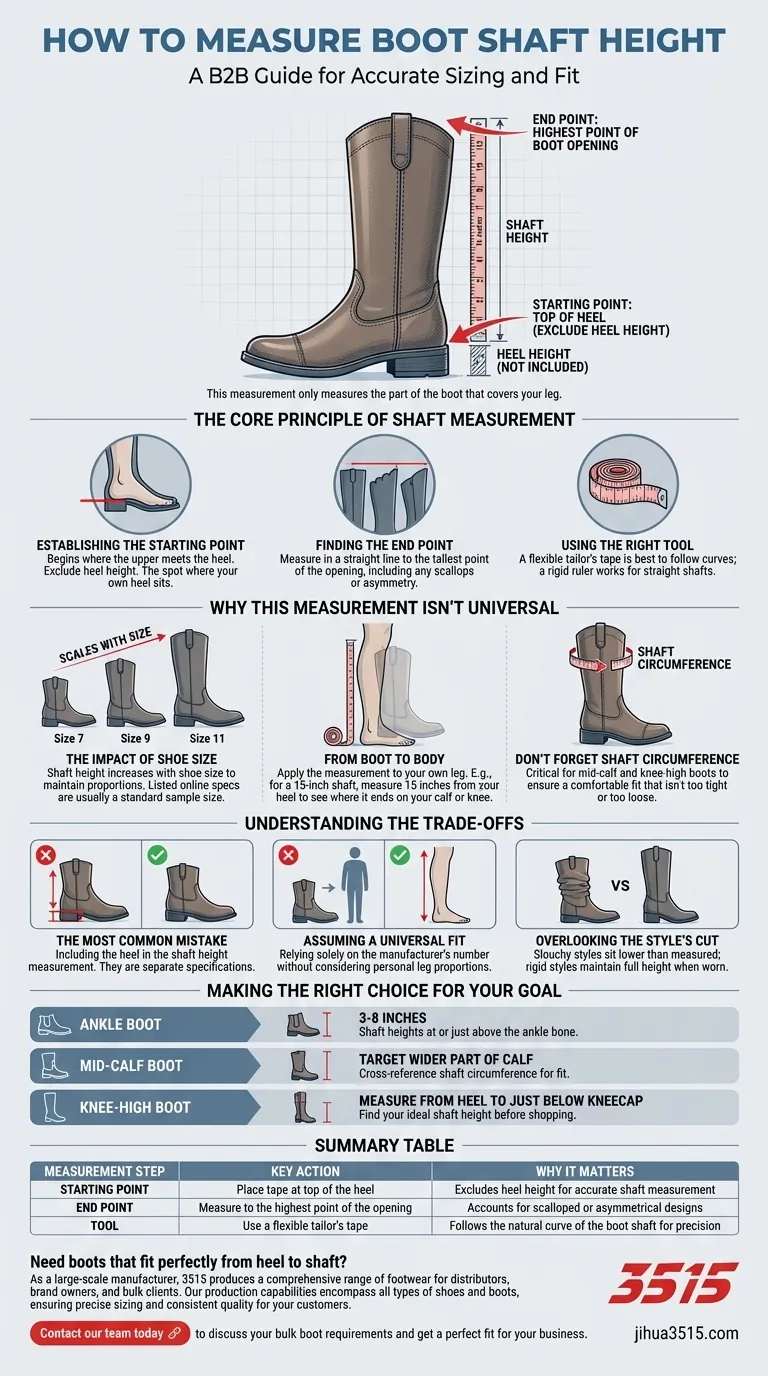

To measure the shaft height of a boot, you place a measuring tape at the top of the heel and measure vertically to the very top edge of the boot shaft. This measurement does not include the heel itself; it only measures the part of the boot that covers your leg.

The concept of shaft height is simple, but its application is personal. It’s not just a product specification; it’s the critical link between the boot's design and how it will actually fit and look on your individual leg.

The Core Principle of Shaft Measurement

Understanding how to measure shaft height correctly is the first step. The process is consistent across almost all boot styles, from ankle boots to over-the-knee designs.

Establishing the Starting Point

The measurement always begins where the upper part of the boot meets the heel. It's crucial to exclude the heel height from this measurement. Think of the starting point as the spot where your own heel would sit inside the boot.

Finding the End Point

Measure in a straight line up to the highest point of the boot's opening, often called the topline. If the boot has a scalloped or asymmetrical design (common in riding or Western boots), always measure to the tallest point.

Using the Right Tool

A flexible tailor's tape measure is the best tool for this job, as it can easily follow any subtle curves of the boot's shaft. For boots with a very straight, rigid shaft, a standard ruler or measuring tape will also work effectively.

Why This Measurement Isn't Universal

A boot's listed shaft height is a helpful guide, but it doesn't tell the whole story. The final fit is a combination of the boot's proportions and your own.

The Impact of Shoe Size

Manufacturers typically scale the shaft height with the shoe size to maintain the boot's intended proportions. A size 11 boot of a particular style will have a slightly taller shaft than a size 7 of the same style. The measurement you see online is usually based on a standard sample size.

From Boot to Body

The most practical way to use shaft height is to apply it to your own leg. If a boot is listed with a 15-inch shaft, take your measuring tape and measure 15 inches up from the bottom of your heel. This will show you precisely where the boot will end on your calf or knee.

Don't Forget Shaft Circumference

Shaft height tells you how high the boot goes, but shaft circumference tells you how wide the opening is. For mid-calf and knee-high boots, this second measurement is just as critical for ensuring a comfortable fit that isn't too tight or too loose.

Understanding the Trade-offs

A few common mistakes can lead to a poor fit. Being aware of them ensures you interpret the measurements correctly.

The Most Common Mistake

The number one error is including the heel in the shaft height measurement. Heel height and shaft height are two completely separate specifications that, together, define the boot's overall profile.

Assuming a Universal Fit

Relying solely on the manufacturer's number without considering your own leg proportions can be misleading. A "knee-high" boot on a shorter person may be an "over-the-knee" boot on someone else, or a "mid-calf" on a taller individual.

Overlooking the Style's Cut

A slouchy boot style will sit lower than its measured shaft height suggests once you wear it. Conversely, a rigid, structured boot will maintain its full height. Consider how the material and design will behave when worn.

Making the Right Choice for Your Goal

Use your understanding of shaft height to deliberately select a boot that achieves your desired look and comfort.

- If your primary focus is an ankle boot: Look for shaft heights that end at or just above the ankle bone, which is typically in the 3 to 8-inch range.

- If your primary focus is a mid-calf boot: Target heights that hit the wider part of your calf and be sure to cross-reference the shaft circumference for a comfortable fit.

- If your primary focus is a knee-high boot: Measure your own leg from your heel to just below your kneecap to find your ideal shaft height before you shop.

By translating this simple measurement into a predictor of personal fit, you can confidently choose a boot that works for your body and your style.

Summary Table:

| Measurement Step | Key Action | Why It Matters |

|---|---|---|

| Starting Point | Place tape at top of the heel | Excludes heel height for accurate shaft measurement |

| End Point | Measure to the highest point of the opening | Accounts for scalloped or asymmetrical designs |

| Tool | Use a flexible tailor's tape | Follows the natural curve of the boot shaft for precision |

Need boots that fit perfectly from heel to shaft?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, ensuring precise sizing and consistent quality for your customers.

Contact our team today to discuss your bulk boot requirements and get a perfect fit for your business.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Wholesale Lightweight Tactical Boots Custom Manufacturer for Desert & Combat Use

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health