At their core, work boots support ankles by acting as an external brace. They use a combination of boot height, a snug lacing system, and stiff materials to physically limit the ankle's side-to-side movement, preventing the twists and rolls that cause sprains and other injuries, especially on uneven ground.

The most critical thing to understand is that true ankle support comes from structural rigidity, not just height. A tall but soft boot offers minimal protection; it's the boot's ability to resist unnatural twisting forces that truly safeguards your ankle.

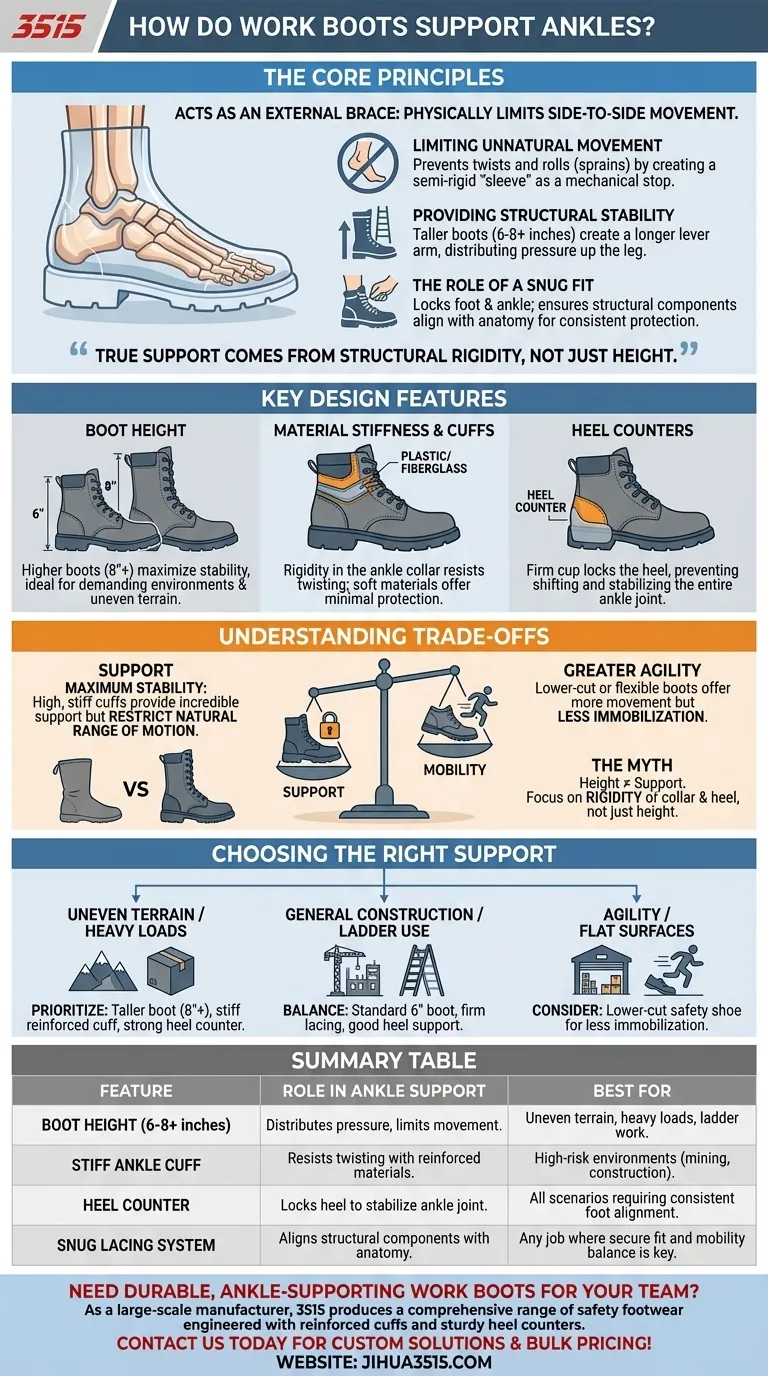

The Core Principles of Ankle Support

To choose the right boot, you first need to understand the mechanical principles that provide protection. Support isn't a single feature but the result of several design elements working together.

Limiting Unnatural Movement

The most common ankle injuries at work are sprains, caused by the ankle rolling inward or outward beyond its normal range of motion. A properly designed work boot physically restricts this dangerous movement.

By creating a semi-rigid "sleeve" around the joint, the boot acts as a mechanical stop, preventing the ligaments from being overstretched.

Providing Structural Stability

A boot's height is a key factor in its stability. Taller boots, typically 6 to 8 inches or higher, create a longer lever arm against which forces must act.

This design helps distribute pressure up the leg instead of concentrating it on the delicate ankle joint, which is crucial when climbing ladders or carrying heavy loads.

The Role of a Snug Fit

A supportive boot is useless if it's not securely fastened to your foot. The lacing system is what locks your foot and ankle in place.

A snug fit ensures the boot's structural components are properly aligned with your anatomy, allowing the boot to move with you and provide consistent protection without chafing or slippage.

Key Design Features That Deliver Support

While the principles are simple, their execution relies on specific components built into the boot.

Boot Height

Higher boots generally offer more support. Tactical or mining boots often feature 8-inch (or taller) shafts to maximize stability in the most demanding environments.

This extra height also provides bonus protection from debris, mud, and other environmental hazards.

Material Stiffness and Cuffs

This is perhaps the most misunderstood aspect of ankle support. Many believe any high-top boot is supportive, but a soft, flexible cuff offers very little real protection against sprains.

True support comes from stiffened materials, often reinforced with plastic or fiberglass, around the ankle collar. This rigidity is what resists the ankle's tendency to roll.

Heel Counters

A heel counter is a firm, cup-like insert built into the back of the boot that cradles your heel.

By locking your heel in place, it prevents it from shifting side-to-side. This stabilizes the base of the foot and, by extension, enhances the stability of the entire ankle joint above it.

Understanding the Trade-offs

Choosing the right work boot is a balancing act. Maximum support is not always the best solution for every job.

Support vs. Mobility

The primary trade-off is between stability and flexibility. A boot with a very high, stiff cuff provides incredible support but will significantly restrict the ankle's natural range of motion.

This can be a drawback for tasks requiring agility or frequent squatting. The stiffest boots immobilize the joint, which is ideal for injury recovery but can feel cumbersome for everyday work.

The Myth of "Any High Boot"

It's crucial to reiterate that height alone does not equal support. A tall boot made of soft, pliable leather or fabric will not prevent your ankle from rolling under pressure.

When evaluating a boot, pay more attention to the rigidity of the ankle collar and heel than to the overall height.

Choosing the Right Support for Your Work

Your specific work environment and tasks should dictate the level of ankle support you need.

- If your primary focus is working on highly uneven terrain or carrying heavy loads: Prioritize a taller boot (8 inches or more) with a visibly stiff, reinforced ankle cuff and a strong heel counter.

- If your primary focus is general construction or frequent ladder use: A standard 6-inch boot with a firm lacing system and good heel support provides an excellent balance of protection and mobility.

- If your primary focus is agility and speed on mostly flat surfaces: A lower-cut safety shoe may be more appropriate, as extreme ankle immobilization is less critical and could hinder performance.

Ultimately, selecting the right boot means matching its protective features directly to the risks you face on the job.

Summary Table:

| Feature | Role in Ankle Support | Best For |

|---|---|---|

| Boot Height (6-8+ inches) | Creates a longer lever arm to distribute pressure and limit side-to-side movement. | Uneven terrain, heavy loads, ladder work. |

| Stiff Ankle Cuff | Resists unnatural twisting forces with reinforced materials (plastic/fiberglass). | High-risk environments like mining or construction. |

| Heel Counter | Locks the heel in place to stabilize the ankle joint and prevent shifting. | All scenarios requiring consistent foot alignment. |

| Snug Lacing System | Ensures the boot's structural components are properly aligned with your anatomy. | Any job where secure fit and mobility balance is key. |

Need durable, ankle-supporting work boots for your team? As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our boots are engineered with reinforced ankle cuffs, sturdy heel counters, and optimal heights to match your specific job risks—ensuring protection without compromising mobility. Contact us today to discuss custom solutions and bulk pricing!

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What are the advantages of using snowshoeing boots for winter biking? Unbeatable Warmth & Value on Flat Pedals

- What are the different types of firefighter boots and their features? Essential Guide for Safety & Performance

- Can insulated work boots be worn in warmer weather? Avoid Discomfort and Foot Health Risks

- What are the advantages of PVC work boots? Get Essential Protection at a Lower Cost

- What safety features are available in work-oriented cowboy boots? Get Certified Protection & Style

- How should work boots be maintained to prolong their lifespan? Essential Care for Long-Lasting Safety

- Why are protective work boots essential in certain industries? Protect Your Workforce from Hazards

- What are pull straps and their variations in cowboy boots? A Guide to Mule Ears, Flush Pulls & More