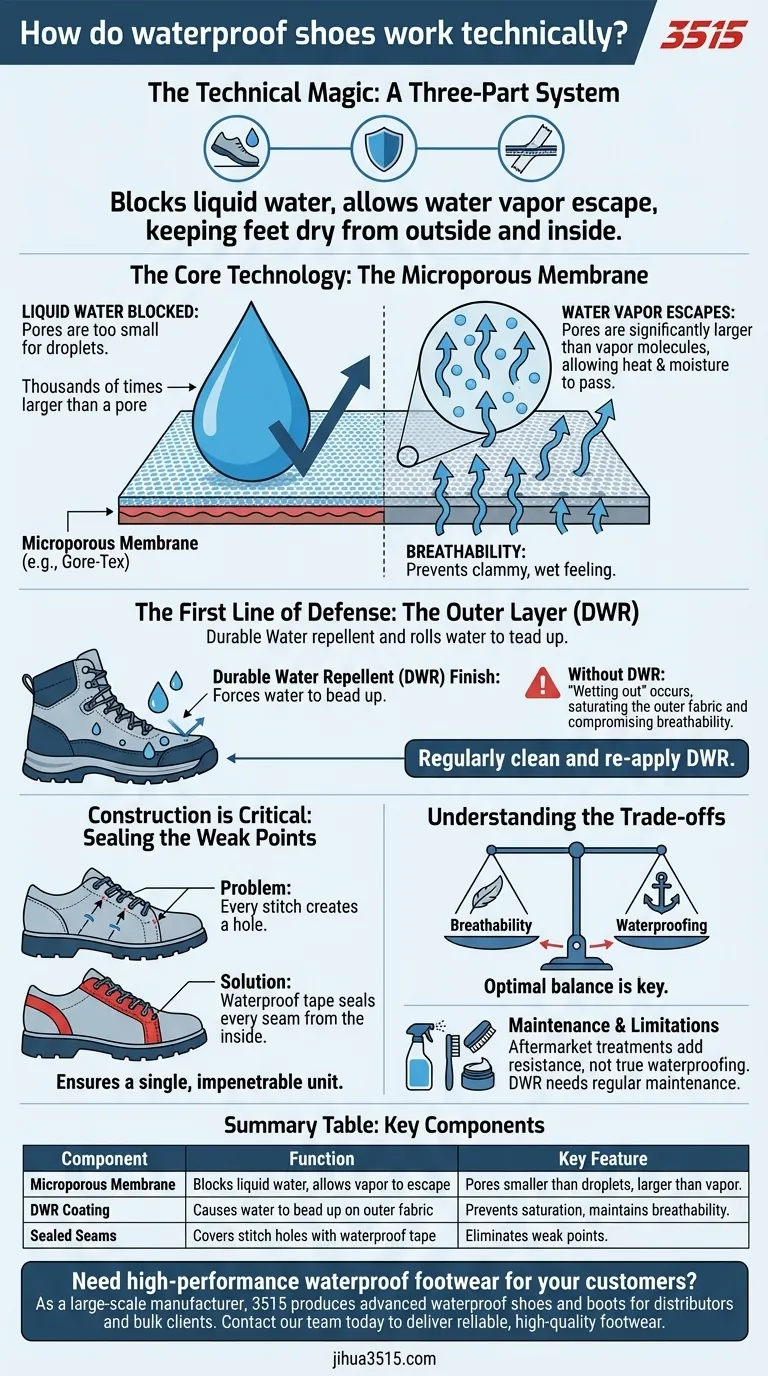

The technical magic of waterproof shoes lies in a three-part system: a high-tech inner membrane with microscopic pores, a water-repellent exterior coating, and sealed construction seams. This combination blocks liquid water from entering while allowing the water vapor from your sweat to escape, keeping your feet dry from both the outside and the inside.

The core principle is selective permeability. A waterproof shoe is engineered as a system that is impassable to large water droplets but permeable to much smaller water vapor molecules, achieving the dual goal of dryness and breathability.

The Core Technology: The Microporous Membrane

How a Membrane Breathes

The heart of a truly waterproof shoe is a specialized liner, or "bootie," made of a microporous material. This membrane is filled with billions of pores per square inch.

Each pore is thousands of times smaller than a single drop of water, making it physically impossible for rain or puddle water to penetrate the barrier.

Simultaneously, each pore is significantly larger than a molecule of water vapor. This allows the heat and moisture from your sweat to pass through the membrane and escape, a process known as breathability.

The Role of Gore-Tex and Similar Materials

Gore-Tex is the most well-known brand of this technology. It's an expanded polytetrafluoroethylene (ePTFE) membrane that embodies this principle.

These materials are engineered to block water and wind completely while retaining a high degree of breathability, preventing the clammy, wet feeling that occurs when sweat gets trapped.

The First Line of Defense: The Outer Layer

The Job of DWR Coatings

The exterior fabric of the shoe (such as leather or nylon) is treated with a Durable Water Repellent (DWR) finish.

This chemical treatment forces water to bead up and roll off the surface of the shoe rather than soak into the outer material.

Why Surface Saturation Matters

Without DWR, the outer fabric would become saturated with water, a state known as "wetting out."

Even though the inner membrane would still be blocking water, a saturated outer layer severely compromises the shoe's breathability. This traps sweat, making your foot feel wet and cold.

Construction is Critical: Sealing the Weak Points

The Problem with Stitches

Every stitch used to assemble a shoe creates a tiny hole. Over thousands of stitches, these holes become a major vulnerability for water to seep through.

To solve this, manufacturers use a special waterproof tape to seal every seam from the inside. This ensures the entire structure is a single, impenetrable unit.

Inherently Waterproof Materials

Some footwear, like traditional rain boots, bypasses this complex system by using materials that are naturally waterproof.

Materials like rubber or certain PVC plastics are non-porous and don't require membranes or coatings. However, this monolithic barrier offers zero breathability, which is why they are not suitable for high-exertion activities.

Understanding the Trade-offs

Breathability vs. Waterproofing

There is always a trade-off. The more robustly waterproof a shoe is, the more its breathability is typically compromised. The goal of modern waterproof footwear is to find the optimal balance for a given activity.

The Limits of Aftermarket Treatments

Waterproofing sprays, waxes, and creams are excellent for adding water resistance to standard footwear. They function like a DWR coating.

However, these treatments cannot make a shoe truly waterproof. They do not seal the seams or provide the breathable barrier of an internal membrane, and they will eventually fail under sustained exposure to moisture.

Maintenance is Non-Negotiable

The DWR coating on the outside of your shoes is not permanent. Dirt, oil, and simple abrasion will wear it away over time.

Once the DWR fails, the shoe will begin to "wet out," losing its breathability. Regular cleaning and re-application of a DWR product is essential to maintain performance.

Making the Right Choice for Your Goal

To ensure your footwear performs as needed, you must align its technology with your intended use.

- If your primary focus is guaranteed dryness in severe weather: Choose footwear with an integrated waterproof membrane (like Gore-Tex) and factory-sealed seams.

- If your primary focus is light protection for casual shoes: Use an appropriate waterproofing spray or wax for the material, but understand its limitations in heavy rain.

- If your primary focus is extending the life of your gear: Regularly clean your shoes and reapply the DWR treatment to maintain both water repellency and breathability.

Ultimately, understanding this multi-part system empowers you to select and maintain footwear that truly serves its purpose.

Summary Table:

| Component | Function | Key Feature |

|---|---|---|

| Microporous Membrane | Blocks liquid water, allows vapor to escape | Pores smaller than water droplets, larger than vapor molecules |

| DWR Coating | Causes water to bead up and roll off the outer fabric | Prevents outer layer saturation, maintains breathability |

| Sealed Seams | Covers stitch holes with waterproof tape | Eliminates weak points where water can enter |

Need high-performance waterproof footwear for your customers?

As a large-scale manufacturer, 3515 produces a comprehensive range of waterproof shoes and boots for distributors, brand owners, and bulk clients. Our technical expertise ensures every pair features advanced membranes, durable coatings, and precision-sealed construction for guaranteed dryness and comfort.

Contact our team today to discuss your specific needs and discover how we can deliver reliable, high-quality waterproof footwear for your market.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

People Also Ask

- How should exotic leather cowboy boots be cared for? A Guide to Preserving Your Investment

- What are the advantages of leather soles? Discover the Hallmarks of Timeless Footwear

- What types of foot problems are associated with repetitive motion or prolonged standing? Protect Your Foundation

- How do advanced manufacturing processes like SPS impact sports equipment quality? Gain a High-Performance Edge

- Why is 100% polyester sewing thread critical for sew-on reflective tapes? Ensure Maximum Safety Garment Durability

- What should be considered when choosing medical boots? Ensure Proper Fit, Support, and Safety

- What are the key considerations for budget bikepacking footwear in cold conditions? Build a Warm, Dry System

- What factors should riders consider when choosing boots? A Guide to Safety, Fit & Performance