In short, sustainable shoes transform plastic waste into a resource. They achieve this by repurposing discarded plastics, most notably PET bottles, into durable materials for footwear. This process directly diverts non-degradable waste from entering landfills and oceans, where it can persist for up to a thousand years.

The true impact of sustainable footwear lies in shifting the manufacturing paradigm from one dependent on new, petroleum-based plastics to a circular model that treats existing waste as a valuable raw material.

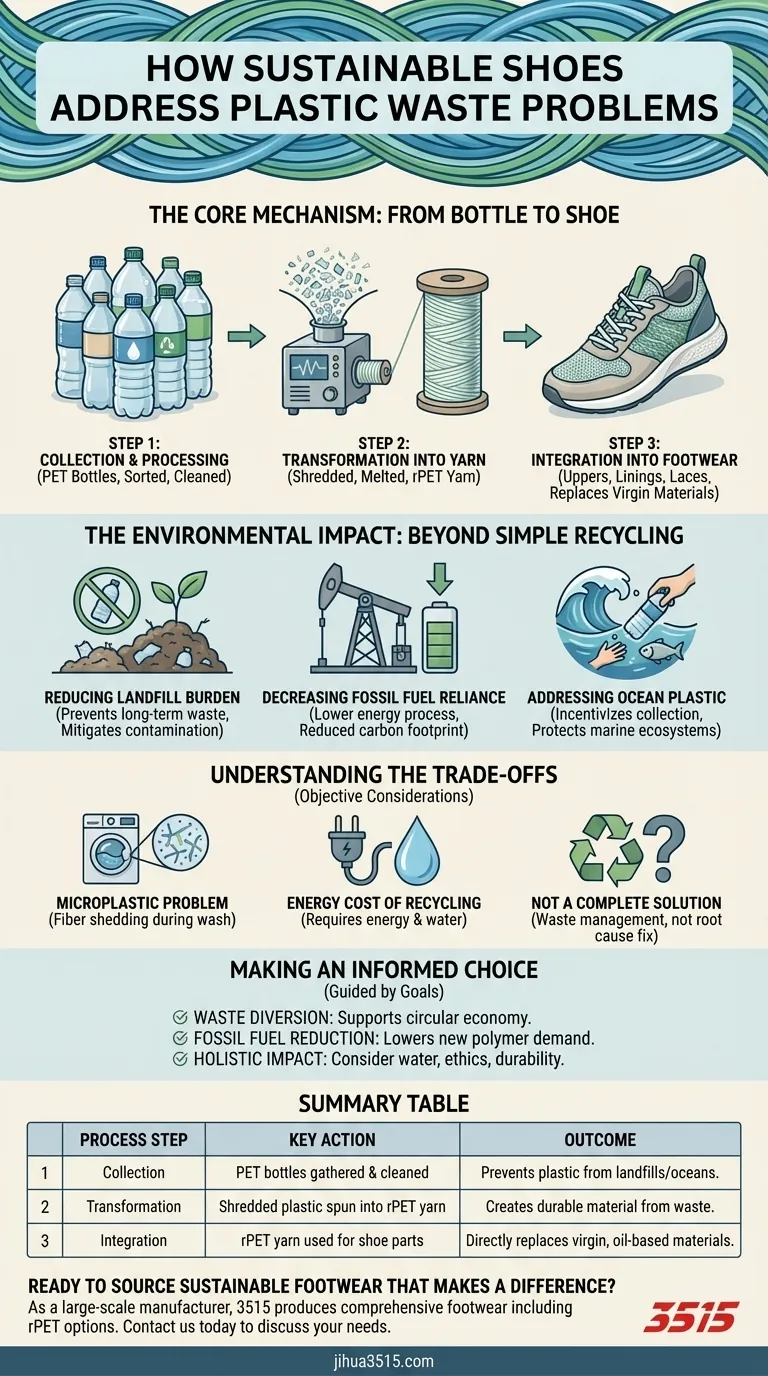

The Core Mechanism: From Bottle to Shoe

To understand how sustainable shoes address plastic waste, it's essential to look at the transformation process. It is a clear, multi-step system designed to give a second life to single-use plastics.

Step 1: Collection and Processing

The journey begins with the collection of plastic waste, primarily PET (polyethylene terephthalate) bottles. These bottles are sorted, cleaned, and stripped of labels and caps to ensure material purity.

Step 2: Transformation into Yarn

The cleaned plastic is shredded into fine flakes. These flakes are then melted down and extruded through tiny holes to create fine filaments, which are spun into a durable, high-quality yarn known as rPET (recycled polyethylene terephthalate).

Step 3: Integration into Footwear

This rPET yarn is then used by footwear manufacturers in the same way as virgin polyester. It is woven or knitted to create shoe uppers, linings, and laces, directly replacing materials that would have been produced from crude oil.

The Environmental Impact: Beyond Simple Recycling

Using rPET is more than just a recycling initiative; it has significant downstream environmental benefits that address the core problems of plastic waste.

Reducing the Landfill Burden

Traditional footwear polymers, derived from crude oil, are not biodegradable. By converting plastic waste into shoes, we prevent it from occupying landfill space for centuries, mitigating soil and water contamination.

Decreasing Reliance on Fossil Fuels

The production of virgin polyester and other plastics is an energy-intensive process that relies entirely on fossil fuels. In contrast, creating rPET uses existing plastic, significantly reducing the demand for new petroleum extraction and its associated carbon footprint.

Addressing Ocean Plastic

A significant portion of plastic waste eventually finds its way into rivers and oceans. By creating a commercial demand for post-consumer plastic, sustainable brands provide a financial incentive for waste collection systems that can intercept this plastic before it pollutes marine ecosystems.

Understanding the Trade-offs

While using recycled plastics is a major step forward, it is essential to approach this solution with a clear understanding of its limitations. Objectivity requires acknowledging that this is not a perfect fix.

The Microplastic Problem

Like virgin polyester, textiles made from rPET can shed microscopic plastic fibers (microplastics) during wear and washing. These particles are too small to be filtered by wastewater treatment plants and can still enter the environment.

The Energy Cost of Recycling

The recycling process itself is not without an environmental cost. It requires significant energy and water to collect, clean, and re-process the plastic, though this footprint is typically smaller than that of producing virgin materials.

Not a Complete Solution

Ultimately, recycling plastic is a waste management strategy, not a final answer to overconsumption. It effectively deals with the waste we have already created but does not solve the root problem of our reliance on single-use plastics in the first place.

Making an Informed Choice

Your decision should be guided by a clear understanding of what this technology can and cannot do. Use your specific environmental goals to frame your choice.

- If your primary focus is waste diversion: Choosing shoes made from recycled plastics is a direct and effective way to support the circular economy and keep waste out of landfills.

- If your primary focus is reducing fossil fuel dependency: Opting for footwear made from rPET helps lower the demand for new, petroleum-based polymers in the textile industry.

- If your primary focus is a holistic environmental impact: View recycled plastic as one important component of a sustainable shoe, and also consider factors like water usage, production ethics, and overall durability.

By understanding both the benefits and the limitations, you can make choices that genuinely align with a more sustainable material lifecycle.

Summary Table:

| Process Step | Key Action | Outcome |

|---|---|---|

| Collection | PET bottles are gathered and cleaned. | Prevents plastic from entering landfills/oceans. |

| Transformation | Shredded plastic is spun into rPET yarn. | Creates a durable material from waste. |

| Integration | rPET yarn is used for uppers, linings, and laces. | Directly replaces virgin, oil-based materials. |

Ready to source sustainable footwear that makes a difference?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including those made with recycled materials like rPET.

We can help you integrate sustainable practices into your product line, offering high-quality, durable footwear that meets market demand and environmental goals.

Contact us today to discuss your sustainable footwear needs and explore our manufacturing solutions.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Durable High-Traction Canvas Sneakers Wholesale & Custom Manufacturing

People Also Ask

- How do specialized footwear categories function as social signals? Master Personal Branding via Strategic Footwear Choices

- What role do 3-axis MEMS accelerometers play in the detection of gait abnormalities? Insights for Smart Footwear.

- How do customized electronic footswitches facilitate synchronized data collection? Precision Gait Timing Explained

- How does styling influence the choice of winter boots? Finding the Perfect Balance for Your Lifestyle

- How can you identify non-marking shoes? A Quick Guide to Protecting Your Floors

- What technical value does standardized footwear provide in long-term gait monitoring? Ensure High-Fidelity Data Accuracy

- What are vegan-friendly alternatives to leather? A Guide to Ethical & Sustainable Materials

- What are the functions of automatic polish dispensers and soft brushes? Enhancing Automated Shoe Polishing Efficiency