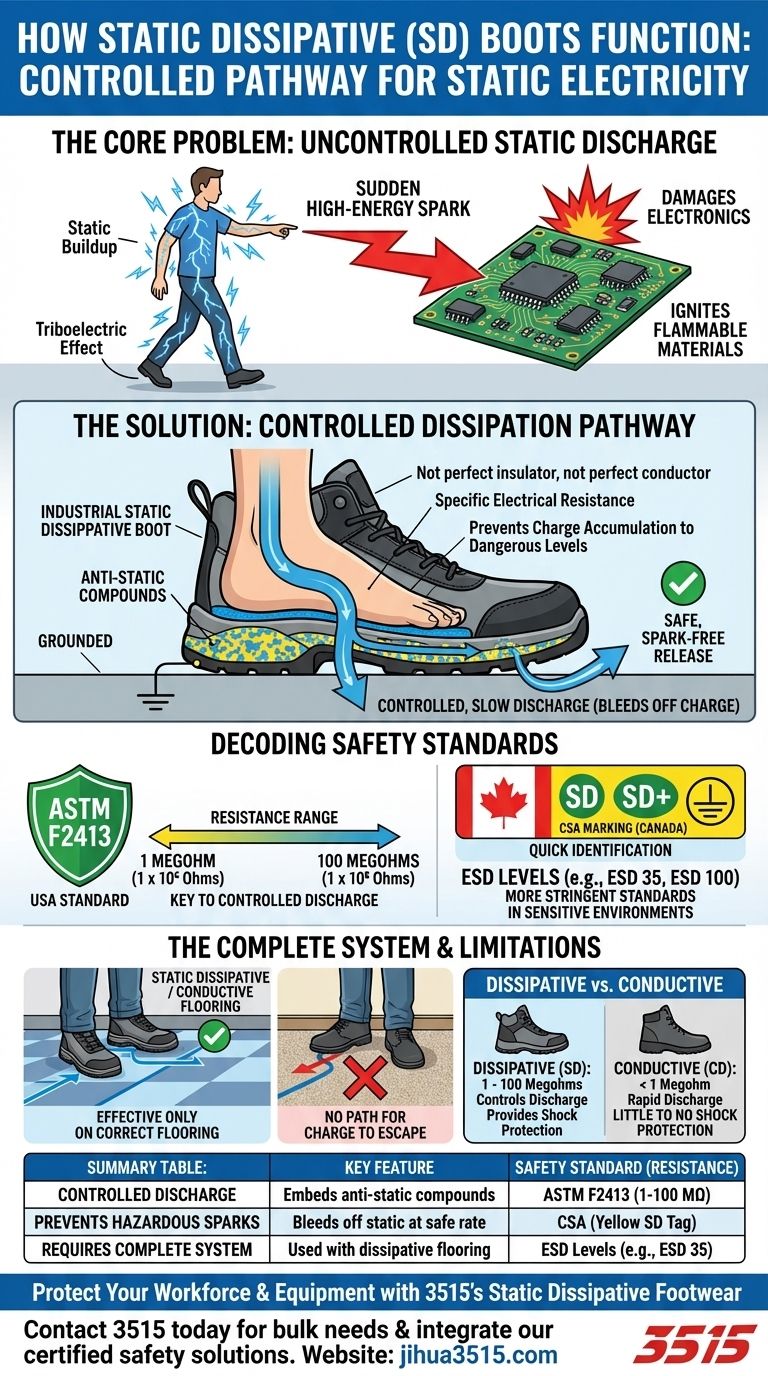

At their core, static dissipative (SD) boots function as a controlled pathway for static electricity. They are engineered to safely and slowly discharge static buildup from your body to the ground, preventing the sudden, high-energy spark that can damage sensitive electronics or ignite flammable materials. This is achieved by embedding special anti-static compounds into the sole material.

The crucial insight is that static dissipative footwear doesn't eliminate static charge, but manages it. By providing a specific, moderate level of electrical resistance, it ensures that any accumulated charge "bleeds off" at a rate that is too slow to create a hazardous spark, yet fast enough to prevent charge from accumulating to dangerous levels.

The Core Problem: Uncontrolled Static Discharge

What Causes Static Buildup?

Static electricity is generated through the triboelectric effect, which occurs when two materials make contact and then separate. This simple act, like walking across a floor, causes electrons to transfer from one surface to the other, creating a charge imbalance on your body.

Without a path to the ground, this charge remains on your body, building up a significant electrical potential.

Why a Sudden Spark is Dangerous

An uncontrolled electrostatic discharge (ESD) event—the spark—occurs when this built-up charge finds an abrupt path to an object with a different potential.

This sudden release of energy is a major risk in two key scenarios:

- Electronics Manufacturing: A tiny, often unfelt spark can be powerful enough to destroy sensitive microchips and electronic components.

- Volatile Environments: In areas with flammable gases, liquids, or dust, a static spark can be the ignition source for a catastrophic fire or explosion.

How Static Dissipative Footwear Provides a Solution

The Principle of Controlled Dissipation

The sole of a static dissipative boot is neither a perfect electrical insulator (like standard rubber) nor a perfect conductor (like metal). It is intentionally engineered to have a specific level of electrical resistance.

This "in-between" property allows the static charge on your body to flow through the boots and into the ground at a controlled, predictable rate.

From Your Body to the Ground

For the system to work, there must be a complete electrical path. Static charge flows from your body, through your socks and the SD boot's insole, out through the specially formulated sole, and into a grounded or static dissipative floor.

This complete pathway ensures that you remain at or near the same electrical potential as the ground, neutralizing any charge as it builds.

Decoding the Safety Standards

The ASTM F2413 Standard

In the United States, the primary standard is ASTM F2413. It specifies that static dissipative footwear must have a electrical resistance between 1 megohm (1 x 10^6 Ohms) and 100 megohms (1 x 10^8 Ohms).

This range is the key to controlled discharge—low enough to allow static to bleed off, but high enough to prevent a dangerous flow of electricity in case of accidental contact with a live electrical circuit.

CSA and Visual Markings

In Canada, the Canadian Standards Association (CSA) uses a distinct visual marker. Compliant static dissipative boots are labeled with a yellow rectangle that features a green "SD" or "SD+" emblem and a grounding symbol.

These markings allow for quick and certain identification of appropriate safety footwear on a job site.

Understanding ESD Levels

You may also see classifications like ESD 35 or ESD 100. These often refer to more stringent standards where the upper limit of resistance is capped at a lower value, such as 35 megohms or 100 megohms, respectively. These are typically used in environments that are extremely sensitive to electrostatic discharge.

Understanding the Limitations

It's a Complete System

Static dissipative boots are only one part of a safety system. They are only effective when used on the correct type of flooring, such as static dissipative or conductive flooring.

If you wear SD boots on an insulated surface like a standard carpet or sealed concrete, there is no path for the charge to escape, and the boots will provide no static protection.

Dissipative vs. Conductive Footwear

It's important not to confuse "dissipative" with "conductive" (CD) footwear. Conductive boots have a much lower electrical resistance (under 1 megohm).

This allows for a very rapid discharge of static electricity and is used in highly controlled environments. However, because of their low resistance, they offer little to no protection from electrical shock hazards.

Making the Right Choice for Your Goal

- If your primary focus is protecting sensitive electronics: You need a reliable system to prevent ESD damage, making certified SD boots paired with the appropriate static-control flooring an essential requirement.

- If your primary focus is preventing ignition in flammable environments: The controlled, spark-free release of static electricity is paramount, meaning SD footwear that meets ASTM or CSA standards is a non-negotiable element of your safety protocol.

- If you require general safety with static control: Always verify that the footwear carries the specific SD markings required by your workplace's safety assessment to ensure you have the correct level of protection.

Ultimately, understanding how these boots function as part of a larger safety system empowers you to mitigate invisible risks effectively.

Summary Table:

| Function | Key Feature | Safety Standard (Resistance) |

|---|---|---|

| Controlled Discharge | Embeds anti-static compounds in the sole | ASTM F2413: 1 - 100 megohms |

| Prevents Hazardous Sparks | Bleeds off static at a safe, controlled rate | CSA: Marked with yellow SD rectangle |

| Requires Complete System | Must be used with conductive/dissipative flooring | ESD Levels: ESD 35, ESD 100 for sensitive areas |

Protect Your Workforce and Equipment with 3515's Static Dissipative Footwear

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our static dissipative boots are engineered to meet strict ASTM and CSA standards, providing the reliable, controlled static dissipation required in electronics manufacturing and volatile environments.

Contact 3515 today to discuss your bulk footwear needs and integrate our safety solutions into your protocol.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

People Also Ask

- What are the advantages and disadvantages of textile uppers in work boots? Find the Right Fit for Your Job

- What features are essential in cowboy boots for construction work? Prioritize Certified Safety & Durability

- What should workers consider regarding warranties for Chemical Resistant boots? Ensure Genuine Protection

- What are the specific requirements for wildland firefighting boots under NFPA 1977? Essential Safety Guide

- What are the key parts of a work boot's interior? The 3 Core Components for All-Day Comfort & Support

- What are the benefits of the integrated energy absorption systems in work boots? Enhance Comfort and Reduce Fatigue

- How do tea-core leather engineer boots age over time? A Guide to Unique Patina Development

- What factors should be considered when choosing wildfire boots? A Guide to NFPA-Certified Safety & Performance