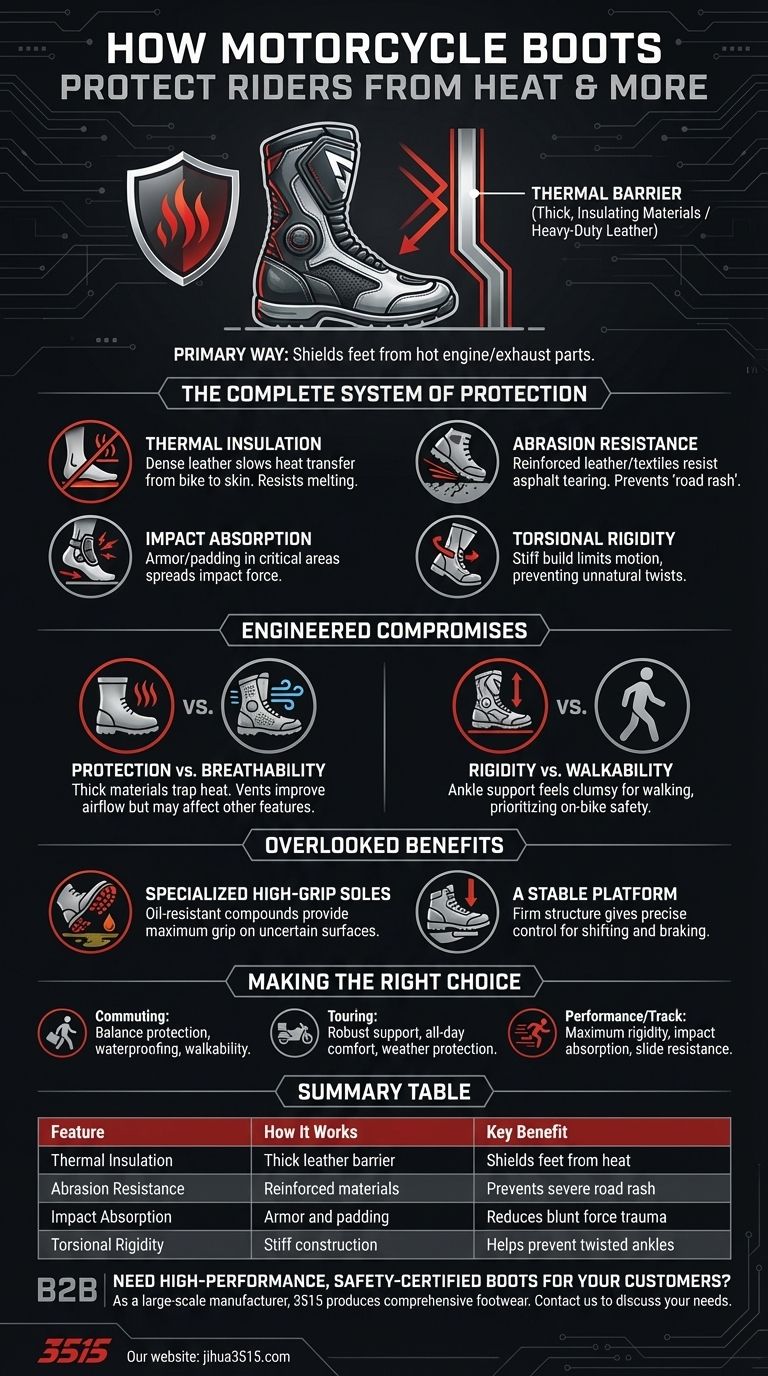

The primary way motorcycle boots protect you from heat is by using thick, insulating materials—most commonly heavy-duty leather—to create a thermal barrier. This shield sits between your feet and the motorcycle's hottest components, like the engine and exhaust pipes, which are often just inches away and can reach extreme temperatures.

While motorcycle boots are excellent at shielding you from engine heat, their true value lies in providing a complete system of protection. They are engineered to address the unique combination of hazards in riding—from abrasion and impact to weather and control—that regular footwear simply cannot handle.

Beyond Heat: The Core Layers of Protection

A common misconception is that motorcycle boots are just thick leather shoes. In reality, they are a piece of technical safety equipment designed to manage multiple, simultaneous risks. Understanding these layers reveals why they are so critical.

### Thermal Insulation (The Obvious Shield)

The most direct answer to the question involves thermal management. The dense structure of full-grain leather is a poor conductor of heat, significantly slowing the transfer of thermal energy from the bike to your skin.

Unlike running shoes or canvas sneakers, which can melt or offer no protection, proper riding boots are built to withstand and insulate against constant, radiant heat.

### Abrasion Resistance (Sliding on Pavement)

In a fall, your feet often make first contact with the road. Motorcycle boots use reinforced leather and advanced textiles specifically chosen for their ability to resist being torn apart by asphalt.

This single feature is a primary defense against "road rash," a severe injury that can easily grind through standard materials in a fraction of a second.

### Impact Absorption (Blunt Force Trauma)

Crashes involve significant impact forces. Purpose-built boots incorporate armor and energy-absorbing padding over critical areas like the ankle, heel, and toe box.

This reinforcement is designed to spread the force of an impact and prevent crushing injuries that could otherwise be debilitating.

### Torsional Rigidity (Preventing Twists)

One of the most common riding injuries is a twisted or broken ankle. Motorcycle boots are intentionally built to be rigid, limiting the foot's range of motion to prevent unnatural and damaging twists during an accident.

This stiffness is a crucial safety feature that differentiates them from flexible hiking or work boots.

Understanding the Trade-offs

No piece of gear is perfect for every situation. Being a trusted advisor means acknowledging the engineered compromises that come with specialized protection.

### Protection vs. Breathability

The same thick materials that block engine heat also trap your body heat. This can lead to sweaty, uncomfortable feet in hot weather.

Some manufacturers address this with perforated leather or vented panels, but this often comes at a slight cost to waterproofing or absolute abrasion resistance.

### Rigidity vs. Walkability

The ankle support and torsional stiffness that protect you on the bike make most motorcycle boots feel clumsy and uncomfortable for walking.

This is not a design flaw; it is an intentional choice that prioritizes on-bike safety over off-bike convenience.

The Overlooked Benefit: Grip and Control

Beyond passive protection, motorcycle boots are an active part of controlling your machine safely.

### Specialized High-Grip Soles

The soles of riding boots are made from compounds designed to be oil-resistant and provide maximum grip on uncertain surfaces. This is critical when you put a foot down at a stoplight that may have a patch of oil or coolant on it.

### A Stable Platform

The boot's firm structure provides a solid and stable platform on the footpegs. This translates to more precise inputs for shifting and braking, giving you better control and feedback from the motorcycle.

Making the Right Choice for Your Riding

Your choice of boot should align directly with your primary use case, as each style prioritizes a different balance of features.

- If your primary focus is daily commuting: Look for boots that balance certified protection with features like waterproofing and a moderate level of walkability.

- If your primary focus is long-distance touring: Prioritize robust support, all-day comfort in a seated position, and superior weather protection.

- If your primary focus is performance or track riding: Seek maximum torsional rigidity, impact absorption, and slide resistance, where off-bike comfort is not a consideration.

Ultimately, choosing proper motorcycle boots is an investment in a piece of equipment engineered specifically for the unique physics and hazards of riding.

Summary Table:

| Protection Feature | How It Works | Key Benefit |

|---|---|---|

| Thermal Insulation | Thick leather acts as a heat barrier | Shields feet from hot engine/exhaust parts |

| Abrasion Resistance | Reinforced materials resist road surface friction | Prevents severe road rash in a slide |

| Impact Absorption | Armor and padding in ankle, heel, and toe | Reduces blunt force trauma during a crash |

| Torsional Rigidity | Stiff construction limits foot movement | Helps prevent twisted or broken ankles |

Need high-performance, safety-certified motorcycle boots for your customers?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective motorcycle boots, engineered with the right balance of thermal insulation, durability, and rider control.

Contact us today to discuss your specific needs and explore how we can deliver reliable, high-quality footwear for your market.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Insulated Safety Boots and Shoes for Wholesale & Bulk Orders

People Also Ask

- What role does comprehensive PPE play in safety culture? Empower Your Workforce with Strategic Material Assurance

- Why are virtual display and interactive technologies necessary for prototype verification? Speed Up Footwear R&D

- What is the role of High-Performance GPUs in training PPE recognition models? Accelerate R&D with Parallel Computing

- How do clinical grading scales like the JOA score assist in orthopedic footwear? Precision Design Through Data

- What is Goodyear Welt Construction? Unlock Decades of Durability & Comfort

- What are the advantages of using nitrile gloves for organophosphorus pesticides? Maximize Chemical Safety & Protection

- Why is moisture management important for keeping feet warm in winter? The key to preventing heat loss.

- How does negative electronic Word of Mouth (eWOM) impact brand equity? Protect Your Footwear Brand's Digital Reputation