Ultimately, fire departments select boots through rigorous, hands-on field testing. This process allows firefighters to evaluate various models, materials, and designs in their specific operational environment to determine which boot best meets their unique combination of safety requirements, performance needs, and durability expectations.

The goal is not to find a single "best" boot, but to identify the right boot that provides the optimal balance of certified protection, long-term durability, and firefighter comfort for a department's specific call types and environmental hazards.

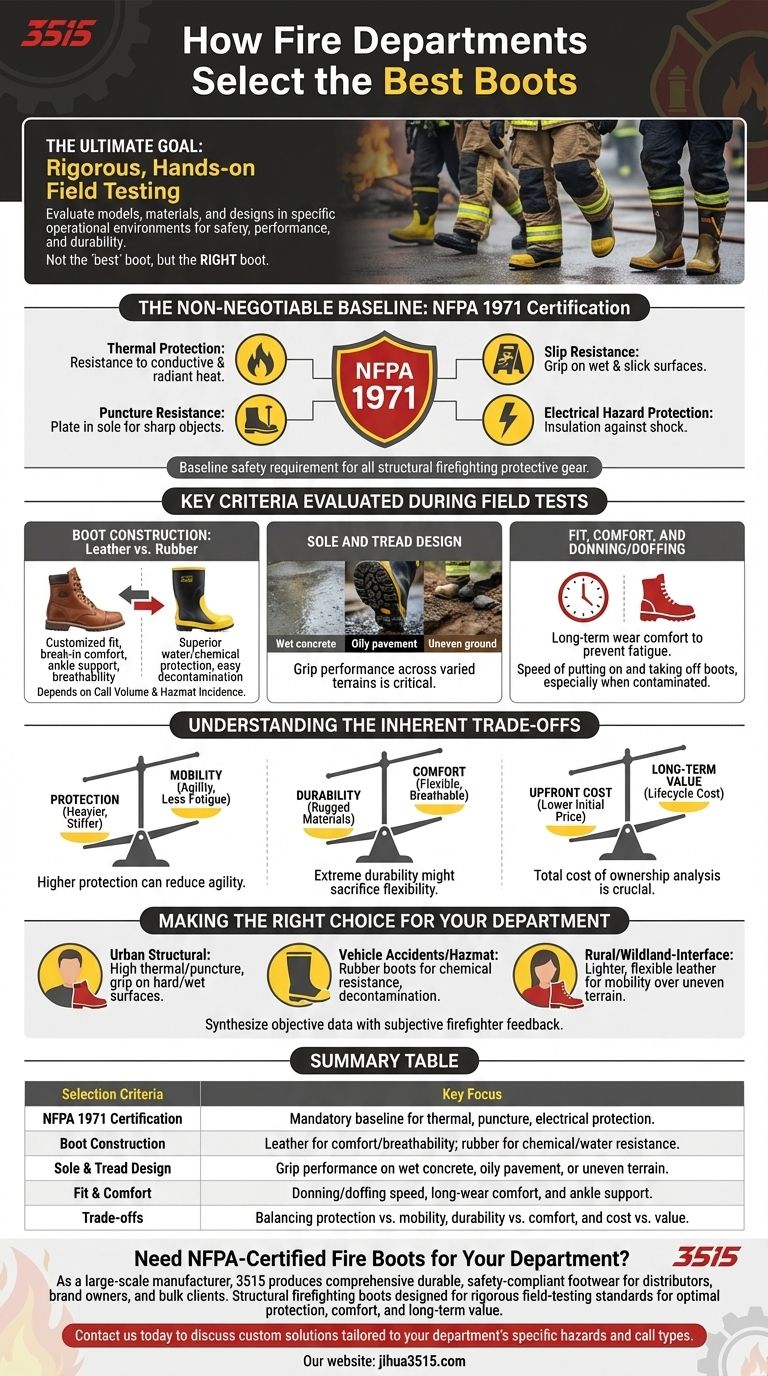

The Non-Negotiable Baseline: NFPA Certification

What is NFPA 1971?

Before any boot is even considered for field testing, it must be certified to meet the National Fire Protection Association (NFPA) 1971 standard. This is the foundational requirement for all structural firefighting protective gear in the United States.

This standard establishes the minimum levels of protection firefighters must have to do their jobs safely. It ensures every certified boot has been independently tested to withstand the extreme conditions of a structure fire.

Key Protections Mandated by NFPA

NFPA 1971 mandates specific performance metrics for every component of a boot. This includes:

- Thermal Protection: Resistance to conductive and radiant heat to prevent burns.

- Puncture Resistance: A plate in the sole to protect the foot from nails, glass, and other sharp objects.

- Slip Resistance: Minimum performance on wet and slick surfaces.

- Electrical Hazard Protection: Insulation against electrical shock.

Compliance with NFPA 1971 is the starting point, ensuring a baseline of safety for any boot a department considers.

Key Criteria Evaluated During Field Tests

Once certified boots are selected for evaluation, departments conduct structured field tests where firefighters wear the boots on actual calls or in realistic training scenarios. The feedback they gather focuses on practical, real-world performance.

Boot Construction: Leather vs. Rubber

There are two primary types of structural firefighting boots, each with distinct advantages.

- Leather boots often provide a more customized fit, breaking in over time for enhanced comfort and ankle support. They also tend to offer better breathability.

- Rubber boots provide superior protection against water and hazardous chemicals, making them easier to decontaminate.

The choice between them often depends on a department’s call volume and the prevalence of hazmat incidents versus long-duration events where comfort is paramount.

Sole and Tread Design

The sole is a critical interface between the firefighter and their environment. Testers pay close attention to how different tread designs perform on various surfaces they commonly encounter, such as wet concrete, oily pavement, or uneven ground.

A boot that grips well in one department’s urban environment may not perform as well in a rural area with more varied terrain.

Fit, Comfort, and Donning/Doffing

A boot can meet every safety standard but fail in the field if it's uncomfortable. Firefighters wear their boots for extended periods, and poor fit leads to fatigue and potential injury.

Evaluators also assess how quickly and easily boots can be put on (donning) during a call and, just as importantly, taken off (doffing), especially when the gear is contaminated.

Understanding the Inherent Trade-offs

Selecting a boot is a balancing act, and every choice involves a compromise. Departments must weigh these factors carefully based on their priorities.

Protection vs. Mobility

Generally, boots with the highest levels of thermal protection and reinforcement are heavier and stiffer. This can reduce a firefighter's agility and increase fatigue over the course of a long incident.

Durability vs. Comfort

The most rugged and durable materials might not be the most flexible or breathable. A department with an extremely high call volume may prioritize durability, while another might favor a more comfortable boot to reduce crew fatigue.

Upfront Cost vs. Long-Term Value

A less expensive boot may seem like a good budget decision, but if it wears out and needs replacement twice as fast as a more expensive, durable option, the total cost of ownership is higher. Departments must analyze the lifecycle cost, not just the initial purchase price.

Making the Right Choice for Your Department

The final selection is made by synthesizing objective performance data with subjective feedback from the firefighters who wore the boots.

- If your primary focus is urban structural firefighting: Prioritize boots with high thermal protection, excellent puncture resistance, and a sole designed for grip on hard, wet surfaces.

- If your department handles frequent vehicle accidents or hazmat calls: Lean towards rubber boots for their superior chemical resistance and ease of decontamination.

- If your response area includes significant rural or wildland-interface zones: Consider lighter, more flexible leather boots that provide better mobility and comfort over uneven terrain for extended periods.

Choosing the right boot is a critical decision that directly impacts firefighter safety and operational effectiveness, which is why a thorough, hands-on evaluation is the industry standard.

Summary Table:

| Selection Criteria | Key Focus |

|---|---|

| NFPA 1971 Certification | Mandatory baseline for thermal, puncture, and electrical hazard protection. |

| Boot Construction | Leather for comfort/breathability; rubber for chemical/water resistance. |

| Sole & Tread Design | Grip performance on wet concrete, oily pavement, or uneven terrain. |

| Fit & Comfort | Donning/doffing speed, long-wear comfort, and ankle support. |

| Trade-offs | Balancing protection vs. mobility, durability vs. comfort, and cost vs. value. |

Need NFPA-Certified Fire Boots for Your Department?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable, safety-compliant footwear for distributors, brand owners, and bulk clients. Our production capabilities include structural firefighting boots designed to meet rigorous field-testing standards—ensuring optimal protection, comfort, and long-term value for your team.

Contact us today to discuss custom solutions tailored to your department’s specific hazards and call types.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- Why might it be beneficial to pre-heat the boots before applying wax? Achieve Deeper, Longer-Lasting Protection

- Are composite toe boots required by OSHA? Focus on the Right Protection for Your Team

- Why are composite toe boots considered lightweight? The Science of Lighter Safety Footwear

- What is the origin of engineer boots? Born in the 1930s for Industrial Workers

- What are the key features of the waterproof pull-on work boot? Superior Protection & Convenience

- How are waterproof boots tested? The Rigorous Lab Process Explained

- How do Robotic Gait Systems verify the durability and safety of mass-produced safety boots? Ensure Unrivaled Performance in Extreme Conditions

- Why is it important for women to wear work boots in the construction industry? Essential Safety & Performance