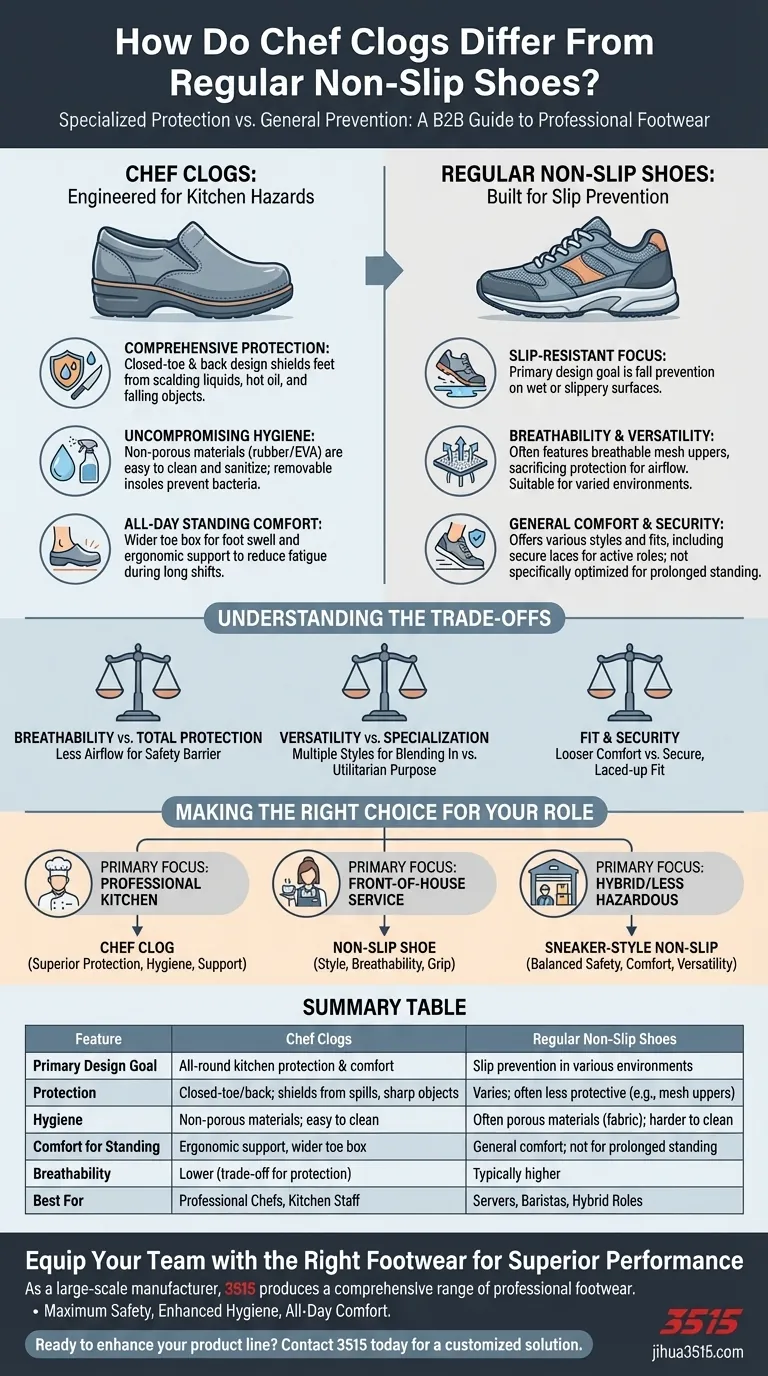

At first glance, chef clogs and non-slip shoes seem to serve the same purpose, but they are fundamentally different tools for different jobs. While all chef clogs are a type of non-slip footwear, they incorporate specialized design features for the unique hazards of a professional kitchen, focusing on protection, hygiene, and all-day standing comfort in ways that general non-slip shoes do not.

The critical distinction is specialization: a standard non-slip shoe is designed only to prevent falls, whereas a chef clog is an engineered system designed to protect you from spills, impacts, and fatigue in a high-intensity kitchen environment.

Beyond the Sole: The Core Design Philosophies

While a slip-resistant tread is the shared foundation, the true differences emerge when you examine the specific demands of a professional kitchen. Chef clogs are built from the ground up to address these challenges.

Protection from Kitchen Hazards

A general-purpose non-slip shoe prevents one type of accident: slipping. A chef clog is designed to prevent many.

Their construction features a closed-toe and often a closed-back design. This solid enclosure acts as a shield, protecting your feet from scalding liquids, hot oil splatters, and the impact of a dropped knife or heavy pan. Many standard non-slip shoes, especially those in a sneaker style, use breathable mesh uppers that offer no such protection.

Uncompromising Hygiene and Cleanliness

Kitchens are messy environments where sanitation is paramount. Chef clogs are almost always made from non-porous, synthetic materials like rubber or EVA foam.

This smooth, seamless surface doesn't absorb liquids and can be wiped clean or even hosed down at the end of a shift. Many also feature removable insoles, allowing for thorough washing and drying to prevent bacterial growth and odors. Fabric-based non-slip shoes are far more difficult to keep sanitized.

Engineered for All-Day Standing

The job of a chef is a marathon of standing, pivoting, and walking on hard floors. Chef clogs are built for this specific kind of endurance.

They typically feature a wider toe box to allow for natural foot swell during a long shift, along with a supportive footbed designed for prolonged weight-bearing. This focus on ergonomic support is purpose-built to reduce fatigue in the feet, legs, and lower back.

Understanding the Trade-offs

Choosing the right shoe involves balancing competing priorities. The specialized nature of chef clogs comes with specific compromises.

Breathability vs. Total Protection

The same non-porous material that makes a clog protective and easy to clean also makes it less breathable than a mesh sneaker. This is a direct trade-off: you sacrifice airflow for a barrier against hot and sharp hazards.

Versatility and Style

General non-slip shoes come in countless styles, from athletic sneakers to professional dress shoes, allowing them to blend in outside of the work environment. Chef clogs have a distinctly utilitarian appearance that is purpose-built for the kitchen and rarely suitable for other settings.

Fit and Security

Many clogs offer a looser fit, which some find comfortable for all-day wear. However, those who need to move very quickly may prefer the secure, laced-up fit of a sneaker-style non-slip shoe. To counter this, many modern clogs include an adjustable strap for a more secure feel.

Making the Right Choice for Your Role

Selecting the correct footwear isn't about which is "better," but which is the right tool for your specific work environment.

- If your primary focus is working in a professional kitchen: A dedicated chef clog is the superior choice for its comprehensive protection, hygiene, and ergonomic support.

- If your primary focus is front-of-house service (server, barista): A standard non-slip shoe provides the necessary grip with more style options and better breathability.

- If your primary focus is a hybrid role or a less hazardous environment: A sneaker-style non-slip shoe offers a balanced compromise between safety, comfort, and versatility.

Ultimately, investing in the right footwear is a foundational decision for your daily safety, comfort, and performance.

Summary Table:

| Feature | Chef Clogs | Regular Non-Slip Shoes |

|---|---|---|

| Primary Design Goal | All-round protection & comfort for kitchens | Slip prevention in various environments |

| Protection | Closed-toe/back; shields from spills, sharp objects | Varies; often less protective (e.g., mesh uppers) |

| Hygiene | Non-porous materials (rubber/EVA); easy to clean/sanitize | Often porous materials (fabric); harder to clean |

| Comfort for Standing | Ergonomic support, wider toe box for all-day wear | General comfort; not specifically for prolonged standing |

| Breathability | Lower (trade-off for protection) | Typically higher |

| Best For | Professional chefs, kitchen staff | Servers, baristas, hybrid roles |

Equip Your Team with the Right Footwear for Superior Performance

As a large-scale manufacturer, 3515 produces a comprehensive range of professional footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety and occupational shoes, including high-performance chef clogs designed for the demanding kitchen environment.

We help you provide footwear that offers:

- Maximum Safety: Protect your staff from kitchen-specific hazards like hot spills and sharp objects.

- Enhanced Hygiene: Easy-to-clean materials that meet strict sanitation standards.

- All-Day Comfort: Ergonomic designs that reduce fatigue and boost productivity during long shifts.

Ready to enhance your product line or equip your team? Let's discuss your specific needs.

Contact 3515 today for a customized solution

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Premium Sport Style Safety Boots for Bulk Orders

People Also Ask

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene