The modern rubber Wellington boot was created when American entrepreneur Hiram Hutchinson applied Charles Goodyear's newly invented vulcanization process to the boot's existing design. In 1853, Hutchinson bought the patent to manufacture rubber footwear and established a factory in France, transforming the leather fashion accessory into a durable, waterproof work boot for agricultural laborers.

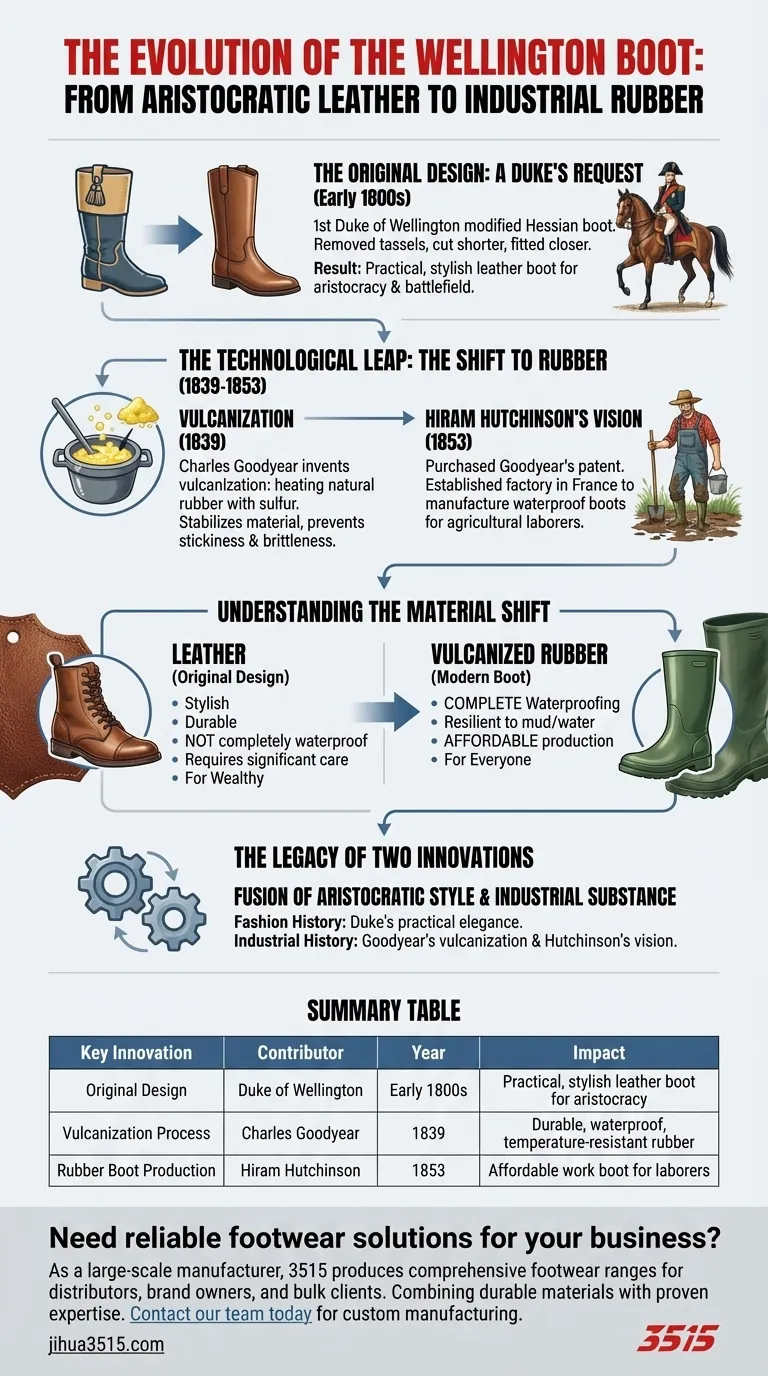

The Wellington boot's history is a story of two distinct innovations: a celebrated Duke created the iconic style for aristocratic fashion, while an industrialist later applied a revolutionary rubber treatment to create the practical, waterproof function we know today.

The Original Design: A Duke's Request

The story of the Wellington boot begins not with rubber, but with leather, and a request from one of Britain's most famous military figures.

From Hessian to Wellington

In the early 19th century, Arthur Wellesley, the 1st Duke of Wellington, instructed his London shoemaker to modify the prevailing military footwear of the time, the Hessian boot.

A Focus on Practicality

The Duke sought a more practical design. He wanted the boot cut shorter, to about mid-calf, and made to fit more closely around the leg. He also had the ornate tassels of the Hessian boot removed.

An Instant Style Icon

The result was a clean, functional leather boot that was tough enough for the battlefield yet stylish enough for evening wear. The "Wellington" boot was quickly adopted by the British aristocracy as a fashionable staple.

The Technological Leap: The Shift to Rubber

For decades, the Wellington remained a leather boot. The transition to rubber was only made possible by a breakthrough in chemical engineering that solved the inherent problems of natural rubber.

The Vulcanization Breakthrough

Charles Goodyear invented the process of vulcanization in 1839, a method of heating natural rubber with sulfur. This process stabilized the material, preventing it from becoming sticky in heat or brittle in cold.

Hiram Hutchinson's Vision

An American entrepreneur named Hiram Hutchinson saw the potential of this new, durable, and waterproof material. He purchased the patent from Goodyear specifically to produce footwear.

Equipping a New Market

Hutchinson moved to France and, in 1853, established a company to manufacture boots from vulcanized rubber. His target audience was not the aristocracy, but the vast agricultural workforce who labored in wet and muddy conditions. This marked the birth of the rubber Wellington boot, or "welly," as a practical item for the working class.

Understanding the Material Shift

The change from leather to rubber was not just a minor alteration; it fundamentally changed the boot's purpose and accessibility.

The Limits of Leather

While stylish and durable, the Duke's original leather boots were not completely waterproof. They required significant care and were not suited for prolonged, harsh use in wet fields.

The Superiority of Vulcanized Rubber

Vulcanized rubber offered complete waterproofing, was far more resilient to mud and water, and could be produced much more affordably. This made the Wellington boot accessible to everyone, not just the wealthy.

The Legacy of Two Innovations

To understand the Wellington boot, you must recognize the two separate moments of genius that created it.

- If your primary focus is on fashion history: The Wellington's origin lies with a trend-setting Duke who prioritized practical elegance over the ornate style of traditional military boots.

- If your primary focus is on industrial history: The modern rubber boot's success is a direct result of Charles Goodyear's vulcanization process and Hiram Hutchinson's vision to apply it to a mass-market need.

Ultimately, the iconic Wellington boot is the perfect fusion of aristocratic style and industrial substance.

Summary Table:

| Key Innovation | Contributor | Year | Impact |

|---|---|---|---|

| Original Design | Duke of Wellington | Early 1800s | Created practical, stylish leather boot for aristocracy |

| Vulcanization Process | Charles Goodyear | 1839 | Made rubber durable, waterproof, and temperature-resistant |

| Rubber Boot Production | Hiram Hutchinson | 1853 | Transformed Wellington into affordable work boot for laborers |

Need reliable footwear solutions for your business? As a large-scale manufacturer, 3515 produces comprehensive footwear ranges for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, combining durable materials with proven manufacturing expertise. Contact our team today to discuss custom footwear manufacturing tailored to your market needs!

Visual Guide

Related Products

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium KPU Injection Athletic Style Safety Shoes

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

People Also Ask

- What should I do if I have chosen the wrong size for my Wellington boots? Get the Perfect Fit & Avoid Future Mistakes

- What other types of footwear are related to men's wellington boots? Explore the Ultimate Guide to Men's Boots

- What are the drawbacks of rubber gardening shoes? Understanding the Trade-offs of Waterproof Footwear

- Are Wellington boots suitable for snowy conditions? Choose the Right Winter Wellies for Safety & Warmth

- What options are available for men's gardening boots? Find the Perfect Fit for Your Garden's Needs

- What are the benefits of ankle wellies for women? Style, Comfort & Everyday Convenience

- Who would benefit from investing in gumboots? Unlock Protection for Work & Play

- How can Hunter boots be styled for winter wear? Leverage Waterproofing for Wet & Slushy Conditions