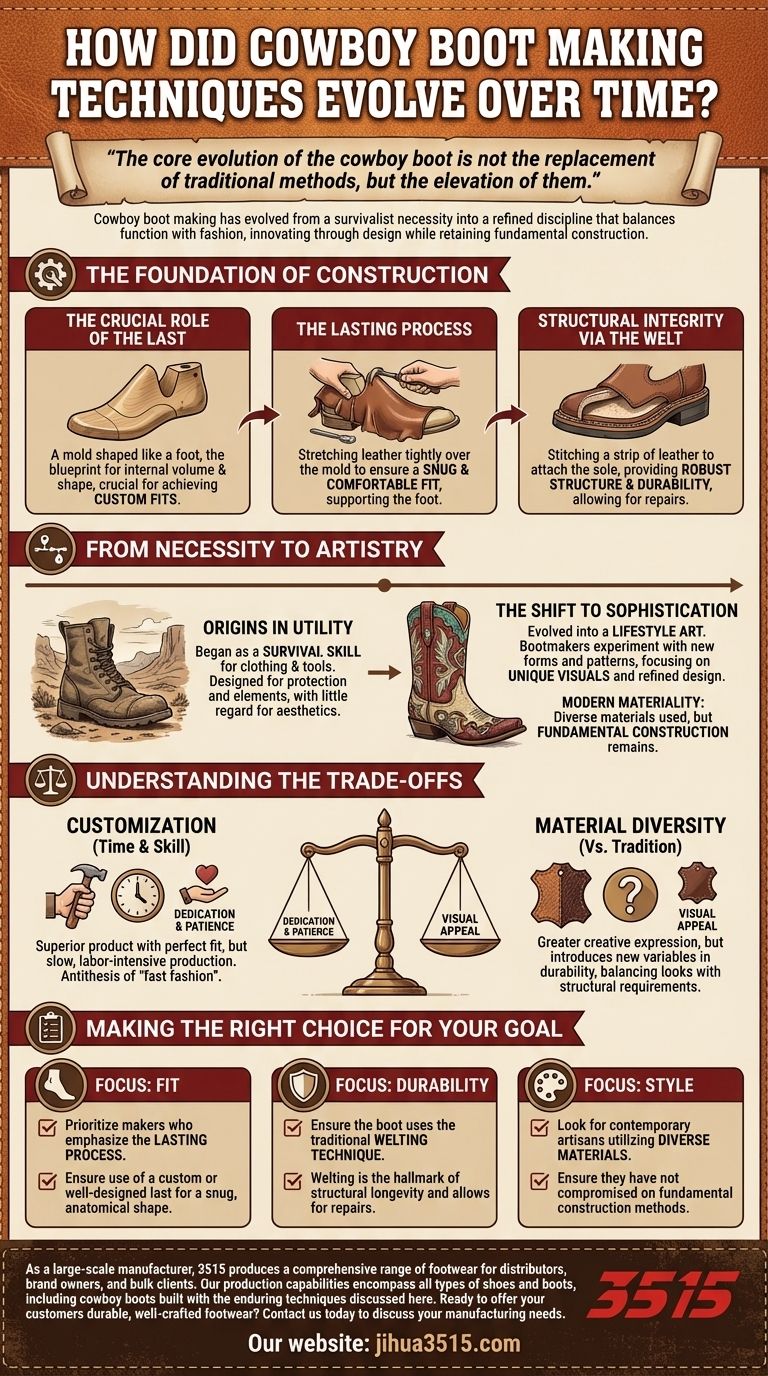

Cowboy boot making has evolved from a survivalist necessity into a refined discipline that balances function with fashion. While the industry has expanded to include diverse materials and intricate decorative patterns, the core technical evolution lies in the refinement of the shoe last to achieve a precise custom fit. Modern bootmakers have largely retained the fundamental construction methods developed over a century ago, choosing to innovate through design rather than altering the structural mechanics of the boot.

The core evolution of the cowboy boot is not the replacement of traditional methods, but the elevation of them. While aesthetic styles have shifted from utility to artistry, the structural integrity still relies on the time-tested processes of lasting and welting to ensure a durable, custom fit.

The Foundation of Construction

Despite the passage of time, the anatomy of a high-quality cowboy boot relies on two critical technical processes. These methods distinguish authentic craftsmanship from mass production.

The Crucial Role of the Last

The most significant technical element in boot making is the shoe last. This is a mold, shaped like a foot, which serves as the blueprint for the boot's internal volume and shape.

Early boot making focused on general utility, but as the craft evolved, the last became essential for achieving custom fits. It allows the maker to account for the nuances of the wearer's foot, ensuring the final product is not just a covering, but a precise match.

The Lasting Process

Once the last is prepared, the lasting process begins. This involves stretching the leather tightly over the mold to force it into shape.

This step is critical for ensuring a snug and comfortable fit. It aligns the leather grain and eliminates slack, creating a boot that supports the foot rather than loosely encasing it.

Structural Integrity via the Welt

The durability of the cowboy boot comes from the welt. This is a specific construction technique where craftsmen stitch a strip of leather to attach the sole to the upper.

This method gives the boot its final, robust structure. Unlike gluing, welting ensures the boot can withstand heavy wear and be repaired, a standard that has persisted from the early days of necessary utility.

From Necessity to Artistry

While the internal mechanics have remained stable, the external application of the craft has undergone a significant transformation.

Origins in Utility

Leather craftsmanship originally began as a survival skill. It was a necessity for creating clothing, housing, and tools in rugged environments.

The early evolution of the boot was driven purely by function. It was designed to protect the wearer and withstand the elements, with little regard for aesthetics.

The Shift to Sophistication

As cowboy boots grew in popularity, the craft evolved from simple tool-making to a sophisticated lifestyle art. Bootmakers began experimenting with new forms and patterns to differentiate their work.

This marked a pivot where the boot became a symbol of fashion and lifestyle, not just a piece of workwear. The demand for unique visuals pushed makers to refine their stitching and design capabilities.

Modern Materiality

Contemporary makers now work with a vast array of diverse materials and decorative elements.

However, even with these modern inputs, they maintain the fundamental construction methods of the past. The evolution is visible on the surface, but the heritage is hidden in the construction.

Understanding the Trade-offs

When analyzing the evolution of boot making, it is important to understand the tension between traditional methods and modern demands.

The Cost of Customization

The reliance on the shoe last for a custom fit creates a superior product, but it requires significant time and skill. This is the antithesis of modern "fast fashion."

A boot made using traditional lasting techniques cannot be mass-produced quickly. The trade-off for a perfect fit is a slower, more labor-intensive production cycle that demands dedication and patience from the artisan.

Material Diversity vs. Tradition

Using diverse, modern materials allows for greater creative expression, but it introduces new variables in durability.

Traditional leathers were chosen for pure function. As makers experiment with exotic or fashion-focused materials, they must balance visual appeal with the structural requirements of the lasting and welting process.

Making the Right Choice for Your Goal

Understanding how these techniques have evolved helps you evaluate the quality of a boot today. Whether you are commissioning a custom pair or buying retail, look for these indicators of craftsmanship.

- If your primary focus is Fit: Prioritize makers who emphasize the lasting process and use a custom or well-designed last to ensure a snug, anatomical shape.

- If your primary focus is Durability: Ensure the boot uses the traditional welting technique to attach the sole, as this is the hallmark of structural longevity.

- If your primary focus is Style: Look for contemporary artisans who utilize diverse materials but have not compromised on the fundamental construction methods of the past.

The true value of a cowboy boot lies in its refusal to abandon the difficult, traditional techniques that make it last a lifetime.

Summary Table:

| Evolution Aspect | Core Technique | Key Benefit |

|---|---|---|

| Fit & Form | Shoe Last & Lasting Process | Achieves a precise, custom fit for comfort and support. |

| Durability | Welted Construction | Ensures structural integrity and allows for repairs, guaranteeing longevity. |

| Style & Aesthetics | Use of Diverse Materials & Decorative Patterns | Blends traditional craftsmanship with modern artistic expression. |

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including cowboy boots built with the enduring techniques discussed here.

Ready to offer your customers durable, well-crafted footwear? Contact us today to discuss your manufacturing needs and leverage our expertise in creating high-quality boots that balance tradition with modern demand.

Visual Guide

Related Products

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

- Wholesale Durable Leather Work Boots | 8-Inch Goodyear Welt Manufacturer

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

People Also Ask

- Why are shoe-mounted distance sensors superior to measuring Foot Clearance? Boost Precision in Gait Analysis

- Why do GBDT and AdaBoost outperform single classifiers in fall risk assessment? Master Complex Gait Data Analysis

- What are some general tips for styling boots effectively? Master Fit, Proportions, and Occasion

- How do professional-grade closed-heel footwear products enhance safety for patients? Superior Stability for Gait Rehab

- What role do high-precision gait analysis systems play in footwear evaluation? Quantitative Data for Perfect Shoe Design

- Why is a Between-subjects design preferred for footwear performance testing? Key Benefits for Material Integrity

- Why is the no-idle constraint significant in industrial footwear manufacturing? Maximize ROI on High-Cost Equipment

- What technical requirements are essential for outsoles in pivoting sports? Boost Grip and Lateral Stability