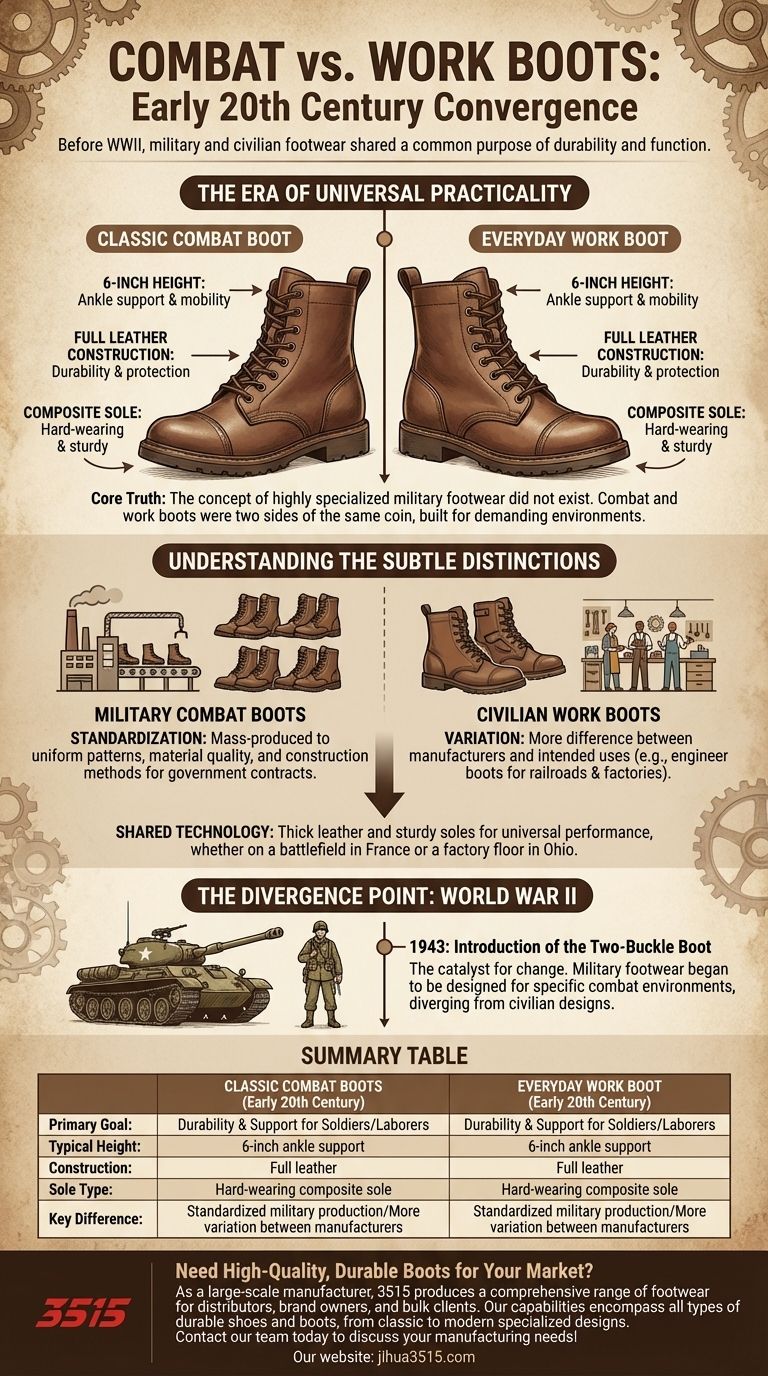

In the first half of the 20th century, classic combat boots were remarkably similar to the everyday work boots worn by civilians. The standard American combat boot until 1943 was a 6-inch laced leather boot with a composite sole, a design that prized durability and support—the same qualities valued by any manual laborer of the era.

The core truth is that the modern concept of highly specialized military footwear did not exist in the early 20th century. Combat boots and civilian work boots were two sides of the same coin, both designed for durability and function in demanding environments.

The Era of Universal Practicality

In the early 1900s, footwear design was driven by necessity. The line between a soldier's equipment and a worker's tool was thin because the physical demands they faced were often analogous.

The Standard-Issue Combat Boot

The quintessential American combat boot before the major specializations of World War II was a practical, no-frills piece of equipment.

Its key features were a 6-inch height for adequate ankle support without restricting movement, a full leather construction for durability, and a hard-wearing composite sole. This design was not a radical invention but an evolution of proven, rugged boot styles.

The Civilian Work Boot Counterpart

Simultaneously, civilian boots followed the same principles. Boots like the "engineer boot," which rose in popularity in the 1930s, were built for blue-collar workers on railroads and in factories.

They were designed for protection and longevity, using the same tough materials and construction methods as their military-issued cousins. The primary goal for both was to create footwear that could withstand abuse day in and day out.

Understanding the Subtle Distinctions

While visually and functionally similar, the key differences were less about design and more about production and purpose.

Manufacturing and Specification

The most significant difference was standardization. Military combat boots were mass-produced to meet specific government contracts and uniform regulations.

This meant a consistent pattern, material quality, and construction method across millions of pairs. Civilian boots, while similar, had more variation between different manufacturers and intended uses.

Function Over Specialized Features

Neither military nor civilian boots of this period had the specialized features we see today, like advanced waterproofing, unique tread patterns for specific terrains, or lightweight synthetic materials.

The shared technology was thick leather and sturdy soles. The goal was universal performance, whether on a battlefield in France or a factory floor in Ohio.

The Divergence Point: World War II

The intense and varied demands of World War II were the catalyst for change. The introduction of the "Two-Buckle Boot" in 1943 marked a clear departure, as military footwear began to be designed for specific combat environments.

This is the point where the design paths of military and civilian boots truly began to diverge, leading to the highly specialized products we recognize today.

How to Apply This to Your Understanding

Understanding this historical context is key to appreciating the evolution of modern footwear.

- If your primary focus is historical accuracy: Recognize that early 20th-century combat boots were essentially a standardized, high-quality version of a common civilian work boot.

- If your primary focus is boot design: View this era as the functional baseline from which all subsequent specialized military and work boot innovations have developed.

- If your primary focus is cultural history: Acknowledge that after the war, these utilitarian boots crossed into the mainstream, becoming symbols of rebellion and subculture, as seen with returning soldiers forming motorcycle clubs.

Ultimately, the story of early combat boots is one of shared purpose and pragmatic design.

Summary Table:

| Feature | Classic Combat Boots (Early 20th Century) | Everyday Work Boots (Early 20th Century) |

|---|---|---|

| Primary Goal | Durability & Support for Soldiers | Durability & Support for Laborers |

| Typical Height | 6-inch ankle support | 6-inch ankle support |

| Construction | Full leather | Full leather |

| Sole Type | Hard-wearing composite sole | Hard-wearing composite sole |

| Key Difference | Standardized military production | More variation between manufacturers |

Need High-Quality, Durable Boots for Your Market?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of durable shoes and boots, from classic work boot designs to modern specialized footwear. Let us help you supply footwear built to last.

Contact our team today to discuss your manufacturing needs!

Visual Guide

Related Products

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

People Also Ask

- What are the main compliance considerations for military boot procurement? Navigating TAA & Domestic Sourcing

- How does high-precision 3D scanning equipment contribute to ergonomic optimization? Advanced Military Boot Development

- What is the historical connection between military uniforms and fashion? Discover the Power of Function & Symbolism

- What are the characteristics of full grain leather used in military boots? Unmatched Durability & Fit

- What inspired the concept of 'super boots' for soldiers? Boost Endurance & Mission Success

- What features contribute to the breathability of military boots? Essential for Comfort and Performance

- What features ensure good traction in military boots? The Ultimate Guide to Stable Footwear

- What are the key features that motorcycle boots should have? Essential Safety & Protection Guide