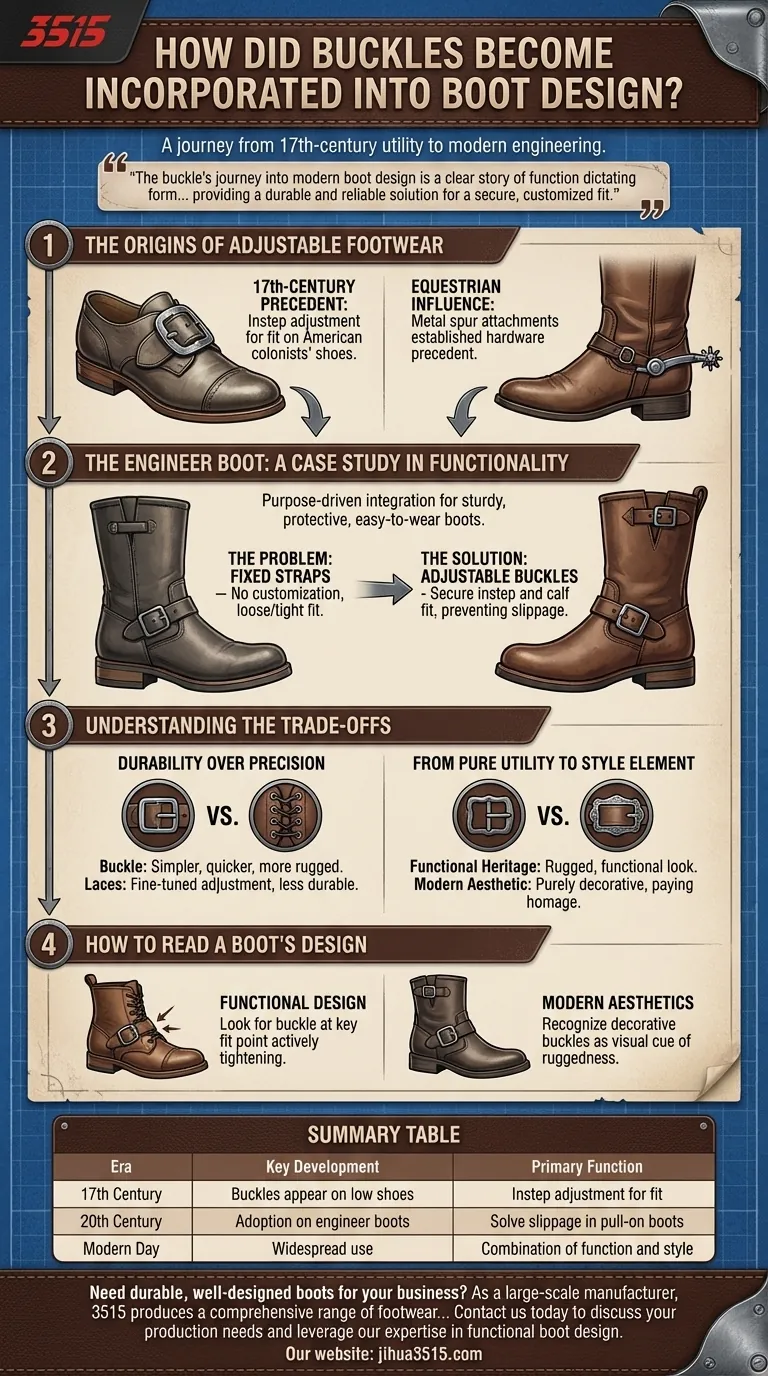

The incorporation of buckles into boot design was a direct evolution driven by the need for functional, adjustable fit. While buckles appeared on low shoes as early as the 17th century, their adoption on boots like the iconic engineer boot was a specific engineering choice, adapting a historical precedent to solve the problem of securing a boot without laces.

The buckle's journey into modern boot design is a clear story of function dictating form. It represents a critical shift from fixed-fit designs to adjustable footwear, providing a durable and reliable solution for a secure, customized fit.

The Origins of Adjustable Footwear

The concept of using a buckle for more than simple closure has deep roots. It was the solution to a timeless problem: how to make one shoe fit securely on feet of slightly different shapes and sizes.

The 17th-Century Precedent

The earliest significant use of buckles for fit adjustment dates to 17th-century footwear. Low-cut buckle shoes, famously worn by American colonists, used a buckle over the instep to tighten the shoe, a clear forerunner to its later use in boots.

The Influence of Equestrian Gear

Early riding boots often lacked buckles for fit adjustment. However, they frequently featured metal spur attachments. This established a precedent for incorporating functional metal hardware onto boot designs, influencing the mindset of future bootmakers.

The Engineer Boot: A Case Study in Functionality

The engineer boot is perhaps the best example of the buckle's purpose-driven integration. Its design arose from a need for a sturdy, protective, and easy-to-wear boot for workers.

The Problem with Fixed Straps

Before the widespread use of adjustable buckles, many pull-on boots used fixed straps or harnesses. These offered no way to customize the fit, meaning the boot was either too loose or too tight for many wearers.

The Buckle as a Solution

Designers adapted the buckle to solve this problem. An adjustable buckle was placed at the instep to cinch the boot securely around the foot, preventing slippage. A second buckle was often added to the top of the boot shaft to adjust its fit around the calf.

A Legacy of Practicality

This was not an aesthetic choice; it was a functional improvement. The buckle provided a durable, reliable, and easily adjusted fastening system that was superior to the fixed designs it replaced.

Understanding the Trade-offs

While effective, the buckle is just one of several closure systems, each with its own advantages and disadvantages. Its role has evolved from pure utility to a combination of function and style.

Durability over Precision

Compared to laces, which offer many points of fine-tuned adjustment, a buckle provides a simpler, quicker, and more rugged solution. It offers less granular control but is far more durable and resistant to failing in harsh conditions.

From Pure Utility to Style Element

Over time, the rugged, functional look of the buckle became a style statement in its own right. Many modern boots now incorporate buckles as a purely aesthetic element, paying homage to their functional heritage without serving the original purpose of adjustability.

How to Read a Boot's Design

By understanding the buckle's history, you can better interpret the intent behind a boot's construction.

- If your primary focus is functional design: Look for boots where the buckle is clearly placed at a key fit point, such as the instep or the top of the shaft, and is designed to actively tighten the leather.

- If your primary focus is modern aesthetics: Recognize that many buckles on contemporary boots are decorative, adding a visual cue of ruggedness that taps into this rich design history.

Ultimately, the humble buckle tells a story of practical innovation, marking the moment when boot design evolved to give the wearer control over their own comfort and security.

Summary Table:

| Era | Key Development | Primary Function |

|---|---|---|

| 17th Century | Buckles appear on low shoes | Instep adjustment for fit |

| 20th Century | Adoption on engineer boots | Solve slippage in pull-on boots |

| Modern Day | Widespread use | Combination of function and style |

Need durable, well-designed boots for your business?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including designs that master the balance of function and style.

Contact us today to discuss your production needs and leverage our expertise in functional boot design.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear