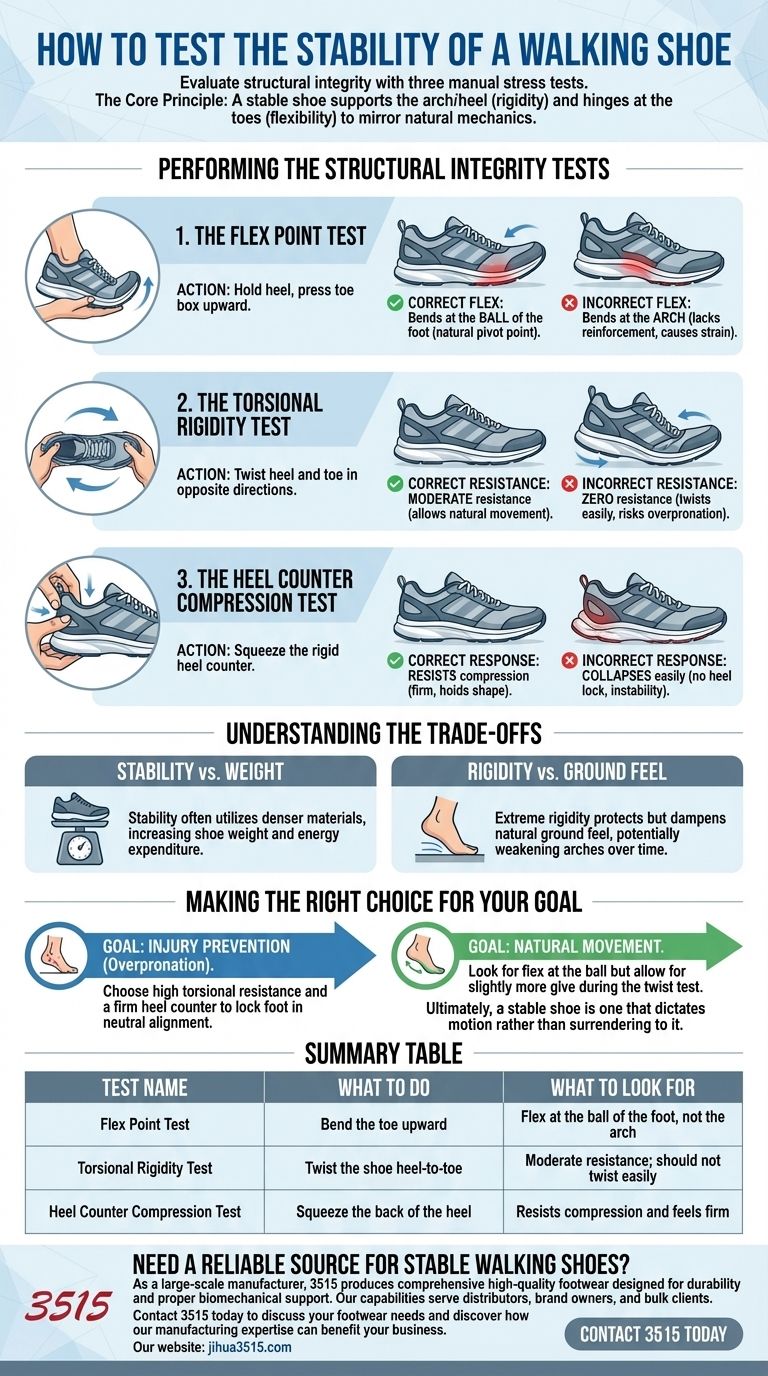

To determine the true stability of a walking shoe, you must perform three manual stress tests to evaluate its structural integrity. First, bend the toe upward to ensure the shoe flexes at the ball of the foot rather than the arch. Second, twist the shoe longitudinally to check for moderate resistance, and third, squeeze the back of the heel to verify it resists compression.

The Core Principle: A stable shoe acts as an extension of your foot's natural mechanics. It must offer rigidity where your foot needs support (the arch and heel) and flexibility where your foot naturally hinges (the toes).

Performing the Structural Integrity Tests

You can assess the biomechanical support of a shoe without putting it on. By applying specific forces to the shoe, you simulate the stress of walking to reveal how the materials will behave under your weight.

The Flex Point Test

Hold the shoe firmly by the heel and press the toe box upward, mimicking the motion of a step. Observe exactly where the sole creates a crease.

The shoe must bend at the ball of the foot, which corresponds to the natural pivot point of your toes.

If the shoe bends halfway along the arch, it lacks essential structural reinforcement. This "mid-foot break" can lead to strain on the plantar fascia and general foot fatigue.

The Torsional Rigidity Test

Grasp the shoe with one hand on the heel and the other on the toe. Twist your hands in opposite directions, as if wringing out a wet towel.

You are looking for moderate resistance. The shoe should allow for some natural movement but should not twist easily into a spiral.

If the shoe offers zero resistance and twists effortlessly, it lacks the torsional stiffness required to prevent the foot from rolling inward (overpronation) during a walk.

The Heel Counter Compression Test

Locate the "heel counter," which is the rigid cup surrounding the back of the heel. Use your thumb and index finger to squeeze this area near the sides.

A stable walking shoe will resist compression. The material should feel firm and hold its shape against your grip.

If the heel counter collapses easily under pressure, the shoe will fail to lock your heel bone (calcaneus) in place. This lack of rearfoot control often leads to ankle instability.

Understanding the Trade-offs

While stability is crucial for support, it is important to recognize that shoe design is a balance between control and freedom.

Stability often comes at the cost of weight. Shoes that pass the twist and squeeze tests with high rigidity often utilize denser materials or plastic shanks. This can make the shoe heavier, which requires more energy to lift with every step.

Rigidity can reduce natural feedback. A shoe that is extremely resistant to twisting protects the foot, but it may also dampen the ground feel. Some walkers prefer a more flexible, "natural" shoe that strengthens the foot muscles, though this increases the risk of strain for those with weak arches.

Making the Right Choice for Your Goal

Once you have performed these tests, interpret the results based on your specific biomechanical needs.

- If your primary focus is Injury Prevention (Overpronation): Choose a shoe with high torsional resistance and a firm heel counter to lock your foot in a neutral alignment.

- If your primary focus is Natural Movement: Look for a shoe that passes the flex test at the ball of the foot but offers slightly more give during the twist test.

Ultimately, a stable shoe is one that dictates motion rather than surrendering to it.

Summary Table:

| Test Name | What to Do | What to Look For |

|---|---|---|

| Flex Point Test | Bend the toe upward. | Shoe must flex at the ball of the foot, not the arch. |

| Torsional Rigidity Test | Twist the shoe heel-to-toe. | Look for moderate resistance; it should not twist easily. |

| Heel Counter Compression Test | Squeeze the back of the heel. | The heel counter should resist compression and feel firm. |

Need a reliable source for stable walking shoes?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality footwear designed for durability and proper biomechanical support. Our production capabilities encompass all types of stable walking shoes and boots perfect for distributors, brand owners, and bulk clients seeking to provide their customers with injury-preventing footwear.

Contact 3515 today to discuss your footwear needs and discover how our manufacturing expertise can benefit your business.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- What historical breakthrough in 1844 contributed to modern shoe sole manufacturing? The Vulcanization Revolution

- What makes rubber sole shoes an economical and practical choice? Unmatched Durability & All-Weather Value

- What is vulcanized rubber and why is it used in products? The Key to Durable, Flexible Footwear

- What makes natural rubber provide excellent traction and grip? Unlocking Superior Performance with Molecular Science

- What are the disadvantages of leather shoe soles? Key Limitations in Traction & Durability