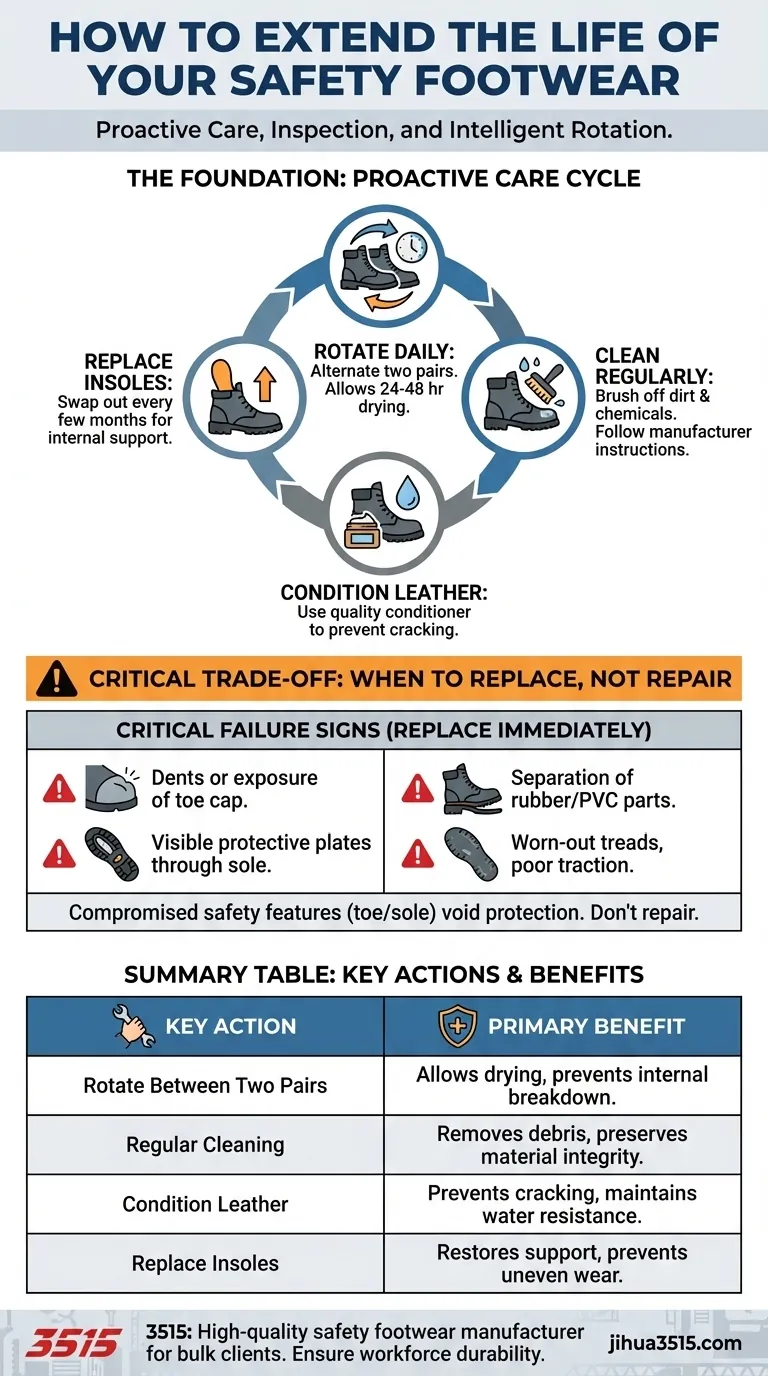

To significantly extend the life of your safety footwear, you must move beyond passive use and adopt a proactive maintenance routine. The most effective methods involve rotating between at least two pairs of boots, keeping them clean according to manufacturer instructions, conditioning leather components, and regularly replacing insoles to maintain internal support.

The lifespan of safety footwear isn't determined by a single action, but by a consistent cycle of proactive care, regular inspection, and intelligent rotation. This approach prevents premature breakdown and ensures your boots protect you effectively every day.

The Foundation: Proactive Care and Maintenance

Your daily habits have the biggest impact on how long your boots will last. Treating your footwear as essential equipment, rather than a disposable item, is the first step toward greater longevity.

Rotate Your Footwear

The single most effective strategy is to own two pairs and alternate them daily. This gives each pair a full 24-48 hours to dry out completely.

This "rest period" allows perspiration and moisture to evaporate, which prevents the breakdown of leather, adhesives, and other materials from the inside out.

Implement a Cleaning Regimen

At the end of your shift, take a moment to brush off dirt, mud, or chemical residues. Caked-on debris can draw moisture out of leather, causing it to crack, and can degrade sole materials over time.

Always follow the specific manufacturer's cleaning instructions to avoid damaging the materials with harsh soaps or solvents.

Condition and Moisturize Leather

For leather boots, regular conditioning is non-negotiable. Use a quality leather conditioner or moisturizer to prevent the material from drying out, cracking, and losing its flexibility.

This simple step maintains the boot's structural integrity and water resistance, preventing small cracks from turning into major failures.

Replace Consumable Components

The sock liners or insoles inside your boots are designed to be replaced. They absorb impact and provide support, but they compress over time.

Replacing your insoles every few months restores comfort and ensures your foot is properly supported, which can prevent uneven wear patterns on the sole of the boot itself.

The Critical Trade-off: When to Replace, Not Repair

Extending the life of your boots is valuable, but it must never come at the expense of your safety. The core purpose of this footwear is protection, and you must know when its protective features are compromised.

The Importance of Regular Inspection

Make it a habit to visually inspect your footwear before each use. A quick check can reveal developing issues before they become critical failures.

Look for deep cuts, punctures, and signs of separation between the upper part of the boot and the sole.

Visible Signs of Critical Failure

You must replace your footwear immediately if you notice any of these signs:

- Dents or exposure of the steel or composite toe cap.

- Visible protective components, such as a puncture-resistant plate or steel shank showing through the sole.

- Separation of rubber or PVC parts, indicating the sole is detaching.

- Worn-out treads that no longer provide adequate traction for your work environment.

Compromised Structural Integrity

Once a core protective element like the safety toe or puncture-resistant sole is damaged, the boot's safety rating is void. No amount of cleaning or conditioning can restore its ability to protect you from an impact or puncture. Continuing to wear compromised footwear creates a false sense of security and exposes you to serious risk.

Making the Right Choice for Your Goal

By focusing on a few key habits, you can directly influence the longevity and performance of your safety gear.

- If your primary focus is maximizing value: Rotating between two pairs of boots is the single most effective long-term strategy for extending footwear life.

- If your primary focus is daily comfort and support: Regularly replacing your insoles every few months is a small investment that yields significant results in both feel and wear patterns.

- If your primary focus is uncompromising safety: Make daily visual inspections a non-negotiable habit and replace boots at the first sign of structural damage.

By treating your safety footwear as a critical tool, you not only extend its life but also ensure it is ready to protect you when it matters most.

Summary Table:

| Key Maintenance Action | Primary Benefit |

|---|---|

| Rotate Between Two Pairs | Allows boots to dry, preventing internal material breakdown. |

| Regular Cleaning | Removes damaging debris and preserves material integrity. |

| Condition Leather | Prevents cracking and maintains water resistance. |

| Replace Insoles | Restores support and comfort, preventing uneven wear. |

Ensure your workforce is equipped with durable, reliable safety footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality safety boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear designed for longevity and safety. Contact us today to discuss your specific needs and discover how we can provide the durable footwear solutions your business depends on.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

People Also Ask

- What type of footwear is required in meatpacking and poultry plants due to slippery conditions? Essential Safety Boots for Slippery Floors

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- What are the primary protective functions of composite-toe boots? A Guide to Modern Safety Footwear