Knowing when to replace your safety footwear is not a matter of guesswork; it's a critical safety check. You must replace your boots or shoes immediately when they show clear signs of damage. This includes any dents in the steel toe, internal protective components becoming visible, the sole separating from the upper part of the shoe, or treads that are excessively worn down.

Your safety footwear should be replaced not based on its age, but on its physical condition. Once any critical protective component is compromised or the sole loses its integrity, the footwear can no longer perform its essential safety function.

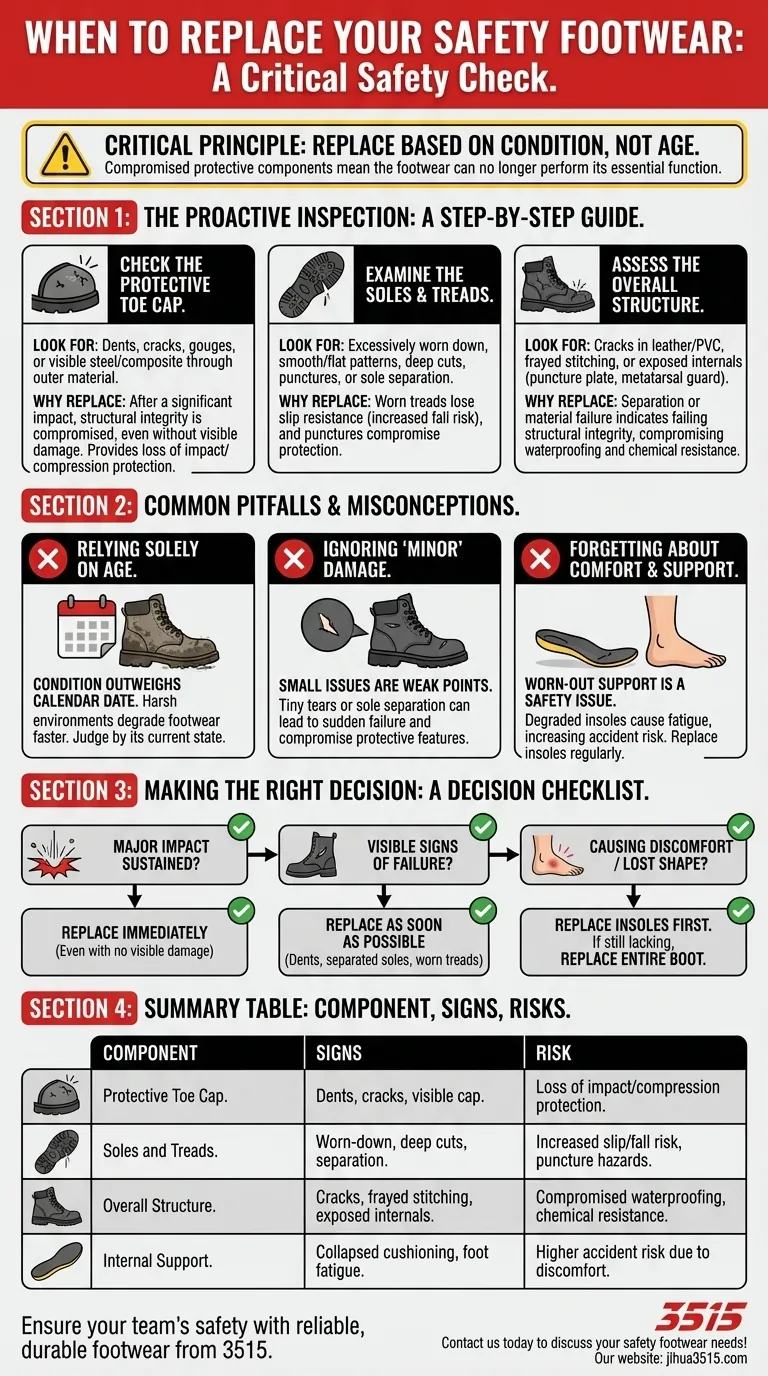

The Proactive Inspection: A Step-by-Step Guide

The most effective way to ensure your footwear is safe is to make inspection a regular habit. Don't wait for a failure. A quick check before each shift can identify problems before they become a danger.

Check the Protective Toe Cap

The toe cap is your first line of defense against impact and compression injuries.

Look for any dents, cracks, or gouges in the protective cap area. If you can see the steel or composite cap through the outer material, it's time for a replacement.

Once a steel toe has been dented from a significant impact, its structural integrity is compromised and it will not provide its intended level of protection in a future incident.

Examine the Soles and Treads

The sole provides slip resistance, puncture protection, and a stable foundation for your entire body.

Check the treads for excessive wear. If the pattern is smooth and flat, the boot has lost its slip-resistant properties, dramatically increasing the risk of falls.

Also inspect for deep cuts, punctures, or any sign that the sole is beginning to separate from the rest of the shoe.

Assess the Overall Structure

The upper part of the footwear protects against splashes, sparks, and abrasions while providing structural support.

Look for cracks in leather or PVC materials, frayed stitching, or exposed internal components like a puncture-resistant plate or metatarsal guard.

Any separation of materials indicates that the boot's structural integrity is failing.

Common Pitfalls and Misconceptions

Relying on simple rules of thumb can create a false sense of security. Understanding these common mistakes is crucial for staying safe.

Relying Solely on Age

A six-month-old boot used in a harsh, chemical-rich environment may need replacement far sooner than a two-year-old boot used for light-duty warehouse work.

Condition always outweighs the calendar date. Judge the footwear on its current state, not how long you've owned it.

Ignoring "Minor" Damage

A small tear or the beginning of a sole separation might seem insignificant, but these are weak points that can fail suddenly under stress.

These minor issues compromise protective features like waterproofing or chemical resistance long before a complete structural failure occurs.

Forgetting About Comfort and Support

While not a direct failure of a protective component, worn-out internal support is a safety issue.

Degraded insoles and collapsed cushioning lead to foot, leg, and back fatigue. Fatigue significantly increases the risk of accidents and injuries on the job. Consider replacing insoles every few months to maintain support.

Making the Right Decision

Use your specific situation to guide your choice. Your goal is not just to have footwear, but to have footwear that works.

- If your footwear has sustained a major impact: Replace it immediately, even if there is no visible damage to the exterior.

- If you notice visible signs of structural failure: Replace the footwear as soon as possible when you see dented toe caps, separated soles, or worn-down treads.

- If the footwear is causing discomfort or has lost its shape: Replace the insoles first, but if support is still lacking, replace the entire boot to prevent fatigue-related injuries.

Treat your safety footwear as a critical piece of equipment, because your protection depends on its integrity.

Summary Table:

| Component to Inspect | Signs It Needs Replacement | Risk of Not Replacing |

|---|---|---|

| Protective Toe Cap | Dents, cracks, or visible cap | Loss of impact/compression protection |

| Soles and Treads | Worn-down treads, deep cuts, separation | Increased slip/fall risk, puncture hazards |

| Overall Structure | Cracks, frayed stitching, exposed internals | Competed waterproofing, chemical resistance |

| Internal Support | Collapsed cushioning, foot fatigue | Higher accident risk due to discomfort |

Ensure your team’s safety with reliable, durable footwear from 3515. As a large-scale manufacturer, we produce a comprehensive range of safety boots and shoes for distributors, brand owners, and bulk clients. Our footwear meets rigorous safety standards and is built to withstand harsh conditions—helping you reduce workplace injuries and maintain compliance.

Contact us today to discuss your safety footwear needs and request a catalog!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Metatarsal Guard Safety Boots Work Shoes

People Also Ask

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What type of footwear is required in meatpacking and poultry plants due to slippery conditions? Essential Safety Boots for Slippery Floors

- What materials are used for safety toes? Choose Steel, Composite, or Aluminum for Your Work Boots

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture