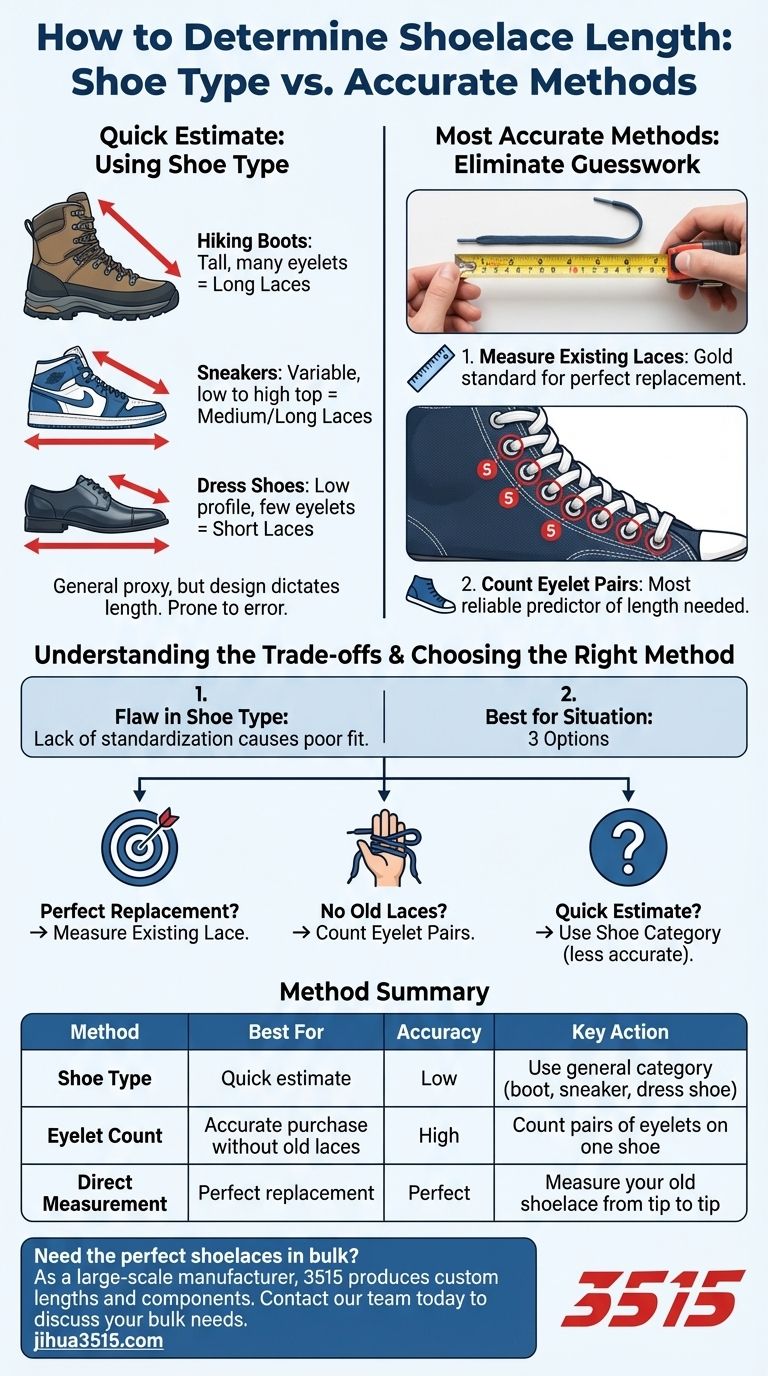

Determining shoelace length by shoe type is a common and convenient starting point, but it's an estimation, not a precise measurement. General categories like hiking boots, street shoes, or dress shoes often correspond to standard lace lengths because their designs typically feature a predictable number of eyelets. However, for a guaranteed fit, the number of eyelets is a far more reliable indicator.

While referencing your shoe's category is a helpful shortcut, the single most accurate way to determine the correct shoelace length is by counting the number of eyelet pairs.

The Logic of Using Shoe Type

Shoe type serves as a general proxy for lace length because the design of a shoe dictates how many eyelets it needs to function correctly. This creates broad, predictable patterns.

How Shoe Design Influences Length

A high-top hiking boot is designed to provide ankle support, which inherently requires more lacing points (eyelets) and therefore a longer shoelace.

Conversely, a low-profile dress shoe needs fewer eyelets to secure the foot, resulting in a much shorter lace.

Common Categories as a Guide

- Work Boots & Hiking Boots: These almost always require long laces due to their height and high number of eyelets needed for a secure fit.

- Street Shoes & Sneakers: This category has the most variability. A low-top sneaker may have 4-5 eyelet pairs, while a high-top version could have 8 or more.

- Dress Shoes: These typically have the fewest eyelets (often 3-5 pairs) and consistently use shorter laces.

The Most Accurate Methods

While shoe type is a good starting point, two other methods offer superior accuracy. Using them eliminates the guesswork.

Method 1: Measure the Existing Laces

This is the gold standard for a perfect replacement. If you are satisfied with the length of your current laces, simply remove one, pull it straight, and measure it from tip to tip.

Method 2: Count the Eyelet Pairs

This is the best method if your original laces are lost or were the wrong length. The number of eyelets (the holes for the laces) on one side of the shoe is the most reliable predictor of the length you need. Most shoelace retailers provide a chart that matches eyelet count to a specific length.

Understanding the Trade-offs

Relying solely on shoe type is fast but introduces a margin of error. Understanding why this happens is key to avoiding a poor fit.

The Flaw in the "Shoe Type" Method

The primary issue is the lack of standardization within a category. One brand's "athletic trainer" might have five pairs of eyelets, while another's has seven.

This difference can easily result in buying laces that are too short to tie or so long they drag on the ground.

Choosing the Right Method for the Situation

Use the shoe type method for a quick, rough estimate when you can't measure or count.

Use the eyelet count for a highly accurate purchase when you don't have the original laces. It's the most reliable universal method.

Use the direct measurement method when you want an identical replacement for a lace you already like.

How to Apply This to Your Goal

Use this simple breakdown to choose the best approach for your specific situation.

- If your primary focus is a perfect replacement: Remove and measure your old laces to get an exact length.

- If your primary focus is accuracy without the old laces: Count the number of eyelet pairs on one shoe and consult a sizing chart.

- If your primary focus is a quick estimate in a store: Use the shoe's category (boot, sneaker, etc.) as a general guide, but accept it may not be precise.

Ultimately, counting the eyelets is the most dependable path to getting the right shoelace length every time.

Summary Table:

| Method | Best For | Accuracy | Key Action |

|---|---|---|---|

| Shoe Type | Quick estimate | Low | Use general category (boot, sneaker, dress shoe) |

| Eyelet Count | Accurate purchase without old laces | High | Count pairs of eyelets on one shoe |

| Direct Measurement | Perfect replacement | Perfect | Measure your old shoelace from tip to tip |

Need the perfect shoelaces in bulk?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear and components for distributors, brand owners, and bulk clients. Whether you need custom shoelace lengths for your specific designs or are sourcing for a large order, our production capabilities ensure you get the right fit, every time.

Contact our team today to discuss your bulk shoelace and footwear needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

- Premium Wholesale Tactical Style Safety Shoes Boots with Quick Lacing

- Wholesale Smart Casual Sneakers with Dial Closure | Factory Direct Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- Why is lightweight design critical for high-intensity footwear? Boost Performance & Reduce Strain

- What factors should physical therapists consider when choosing work shoes? Essential Features for All-Day Comfort and Safety

- What is the new gold standard for ankle sprain recovery? Discover the POLICE Principle for Faster Healing

- How do high-performance wireless microprocessors function within a smart fall detection system? Key Roles & Tech

- Why are Teflon cables and specialized ankle straps utilized in treadmill-based trip simulation experiments for footwear testing? Ensure Valid Results.

- Why are industrial presses critical for footwear production? Unlock Precision Molding & Pre-Fabrication Success

- What are wool boots primarily used for? Unbeatable Warmth and Dry Comfort in Winter

- What are Flip-Flops best suited for? The Ultimate Guide to Casual Footwear