To identify a Goodyear welted shoe, look for the visible row of stitching that runs along the top edge of the outsole, connecting it to a thin strip of material—the welt—that sits between the sole and the shoe's upper. This construction creates a distinct, layered look when viewed from the side and gives the shoe a sturdy, substantial feel.

The key to identifying a Goodyear welt is understanding its function: it's a separate component stitched between the upper and the outsole. This external stitching is the most reliable visual cue, signaling a shoe built for durability and repair.

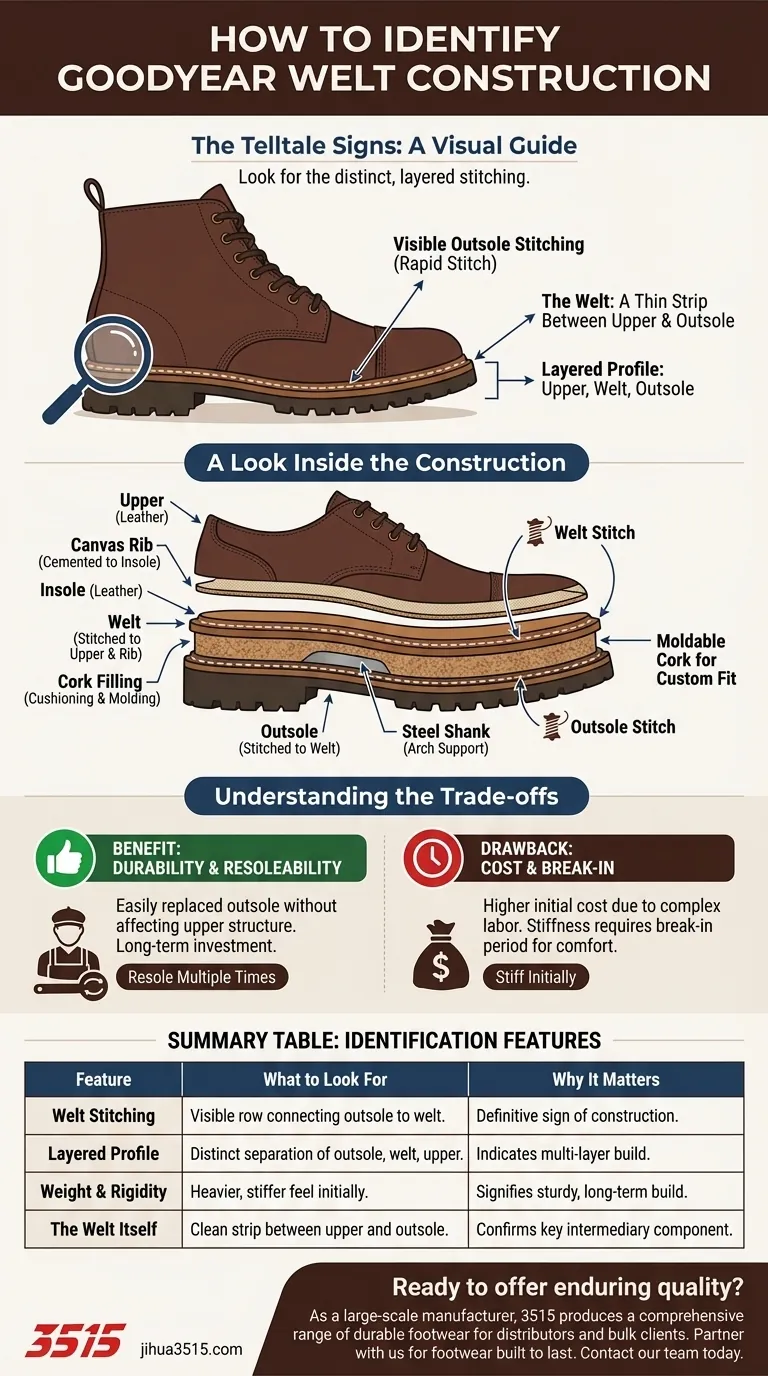

A Look Inside the Construction

To confidently spot a Goodyear welt, it helps to understand what’s happening beneath the surface. This method is prized not just for what you can see, but for its complex, layered internal structure.

The Role of the Welt

The welt is a strip of material, typically leather, that runs along the perimeter of the outsole. It acts as a crucial intermediary. The shoe's upper is first stitched to the welt, and then the welt is stitched to the outsole.

This two-level stitching process is the core principle of the Goodyear welt.

The Hidden Components

Inside the shoe, a canvas rib is cemented to the insole. The upper and the welt are sewn together through this rib, creating a secure internal bond.

This leaves a cavity between the insole and the outsole, which is filled with a layer of cork. This cork filling provides cushioning, insulation, and over time, molds to the shape of your foot.

The Telltale Signs: A Visual Guide

With an understanding of the construction, you can now look for specific, reliable indicators on the shoe itself.

Examine the Welt Stitching

The most definitive sign is the outsole stitching, often called a rapid stitch. This is a thick, durable thread you can see running around the edge of the sole.

You should be able to see this stitch from both the top (looking down at the welt) and the bottom of the shoe.

Identify the Welt Itself

Look for the distinct strip of material sandwiched between the leather upper and the thicker outsole. This is the welt. It creates a small buffer or ledge around the base of the shoe.

On a well-made shoe, this strip will be cleanly finished and clearly visible.

Observe the Layered Profile

View the shoe from the side. You should be able to distinguish the separate layers: the outsole at the bottom, the thin welt above it, and finally the upper. This layered appearance is characteristic of the construction.

Feel the Weight and Rigidity

Goodyear welted shoes are generally heavier and more rigid out of the box compared to more flexible constructions. This sturdiness comes from the multiple layers, the cork filling, and a metal shank often embedded for arch support.

Understanding the Trade-offs

No construction method is perfect for every situation. Being a trusted advisor means acknowledging the pros and cons.

The Benefit: Durability and Resoleability

The primary advantage is repairability. Because the outsole is stitched to the welt and not directly to the upper, a cobbler can easily remove the old sole and stitch on a new one multiple times without compromising the shoe's structure.

This makes Goodyear welted footwear a long-term investment.

The Drawback: Cost and Break-In Period

The complexity of the process requires skilled labor and more materials, making these shoes more expensive upfront.

They also require a break-in period. The initial stiffness from the layers and cork needs time to soften and conform to your foot.

The Common Misconception: Waterproofing

While the construction is highly water-resistant due to the welt, it is not fully waterproof. Water can eventually penetrate the stitch holes with prolonged exposure to wet conditions.

Making the Right Choice for Your Goal

Ultimately, identifying a Goodyear welt is about assessing if a shoe meets your specific needs for quality and longevity.

- If your primary focus is longevity and repairability: The Goodyear welt is the undisputed standard, offering the ability to resole your shoes for years of use.

- If your primary focus is immediate, out-of-the-box comfort: Be prepared for a break-in period, as the rigid construction takes time to mold to your foot.

- If your primary focus is value over time: A Goodyear welt shoe is a sound investment, as its higher initial cost is offset by its extended lifespan.

Recognizing these construction details empowers you to choose footwear that is not just worn, but truly invested in.

Summary Table:

| Identification Feature | What to Look For | Why It Matters |

|---|---|---|

| Welt Stitching | A visible row of stitching connecting the outsole to a thin welt strip. | The most definitive sign of Goodyear welt construction. |

| Layered Profile | A distinct separation between the outsole, welt, and upper when viewed from the side. | Indicates the multi-layer construction for durability. |

| Weight & Rigidity | Shoes feel heavier and more rigid initially due to cork filling and structure. | Signifies a sturdy build designed for long-term wear. |

| The Welt Itself | A cleanly finished strip of material (e.g., leather) between the upper and outsole. | Confirms the presence of the key intermediary component. |

Ready to offer your customers the enduring quality of Goodyear welt construction?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our expertise ensures every pair meets the highest standards of craftsmanship and longevity.

Partner with us to provide footwear built to last. Contact our team today to discuss your production needs and explore our capabilities.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

People Also Ask

- What are the best boot colors to pair with a suit? Master Formal & Modern Style

- What are the recommended features for cowboy boots in a formal work environment? Achieve Professional Style & Comfort

- What are the standout features of the best splurge dress shoes? A Guide to Superior Craftsmanship & Comfort

- What are the styling options for Wingtip (Derby) boots? Master Business Casual & Weekend Style

- What is an alternative to self-cleaning leather shoes? Effortless Maintenance Strategies

- What are the different types of loafers? A Guide to Penny, Tassel & Horsebit Styles

- How does neural style transfer technology assist in the personalized pattern design of formal and business shoes?

- How does the cost of Goodyear-welted shoes compare to their value over time? A Long-Term Investment Analysis