To ensure your employees have the right work boots, you must move beyond simple recommendations and implement a structured protective footwear program. This begins with a formal hazard assessment of your workplace, which then informs a clear, written policy that specifies mandatory safety features and performance standards for all required footwear.

The most effective way to guarantee correct footwear is not by leaving it to chance, but by establishing a proactive system. This system involves assessing specific job-site risks, defining non-negotiable boot features, and creating a clear policy for procurement and enforcement.

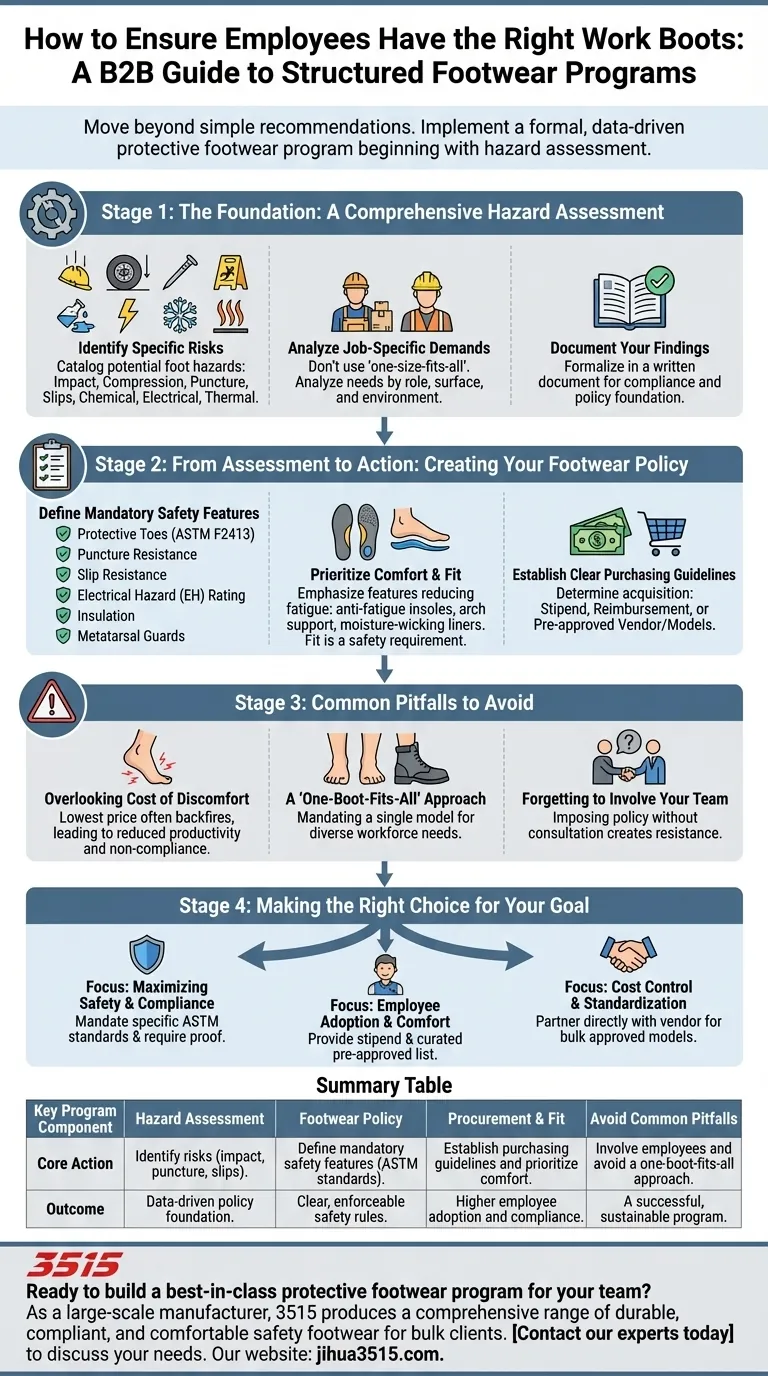

The Foundation: A Comprehensive Hazard Assessment

Before you can define the right boot, you must deeply understand your workplace risks. A guess is not a strategy; a formal assessment is the only reliable starting point for a successful and compliant safety program.

Identify Specific Workplace Risks

Your first step is to catalog every potential foot hazard. This includes risks from falling objects (impact), rolling equipment (compression), sharp materials on the ground (puncture), slick floors (slips), and exposure to chemicals, extreme temperatures, or live electrical circuits.

Analyze Job-Specific Demands

A "one-size-fits-all" boot policy is rarely effective. Analyze the distinct needs of each role. A warehouse worker on concrete floors all day has different needs than an electrician on a construction site. Consider the surfaces they walk on, the distances they cover, and the environmental conditions they face.

Document Your Findings

Formalize your assessment in a written document. This record is crucial for demonstrating compliance with regulatory bodies like OSHA and serves as the objective foundation for creating your company's official footwear policy.

From Assessment to Action: Creating Your Footwear Policy

With your hazard assessment complete, you can now build a clear and enforceable policy. This document translates your findings into actionable rules for your employees.

Define Mandatory Safety Features

Create a checklist of required features based on your documented risks. This removes ambiguity and ensures a baseline level of protection.

Key features to consider include:

- Protective Toes: Steel, alloy, or composite caps (ASTM F2413).

- Puncture Resistance: Midsoles that protect against nails and sharps.

- Slip Resistance: Outsoles designed for the specific surfaces in your facility.

- Electrical Hazard (EH) Rating: For roles working near live circuits.

- Insulation: For work in cold environments.

- Metatarsal Guards: For protection of the top of the foot.

Prioritize Comfort and Fit

Safety features are useless if the boots are too uncomfortable to wear correctly. Your policy should also emphasize features that reduce fatigue and prevent injury, such as anti-fatigue insoles, proper arch support, and moisture-wicking liners. A proper fit is a safety requirement.

Establish Clear Purchasing Guidelines

Your policy must state how employees will acquire compliant boots. Common models include a company-provided stipend or allowance, a reimbursement program upon proof of purchase, or direct purchasing from a list of pre-approved vendors and models.

Common Pitfalls to Avoid

Implementing a program is straightforward, but several common mistakes can undermine its effectiveness. Being aware of these helps ensure your investment in safety pays off.

Overlooking the Cost of Discomfort

Choosing boots based on the lowest price often backfires. Uncomfortable footwear leads to employee fatigue, reduced productivity, and even a refusal to wear the required protection, completely defeating the purpose of the program.

A "One-Boot-Fits-All" Approach

Mandating a single boot model for a diverse workforce is a frequent error. This fails to account for the different hazards and physical demands of various roles, leaving some employees either under-protected or burdened with unnecessary features.

Forgetting to Involve Your Team

Imposing a policy without consultation can create resistance. Involving employees in the selection process by offering several pre-approved choices gives them a sense of ownership and dramatically increases buy-in and compliance.

Making the Right Choice for Your Goal

Your final program should align with your company's primary objectives. Use your hazard assessment as a guide to implement the best strategy for your team.

- If your primary focus is maximizing safety and compliance: Mandate specific ASTM or other certified standards in your policy and require proof that any purchased boot meets them.

- If your primary focus is employee adoption and comfort: Provide a stipend and a curated list of pre-approved boot models, giving employees a choice within safe parameters.

- If your primary focus is cost control and standardization: Partner directly with a safety footwear vendor to select a few approved models that cover your core risks and can be purchased in bulk.

Ultimately, a well-structured footwear program is a direct investment in the safety and productivity of your most valuable asset: your people.

Summary Table:

| Key Program Component | Core Action | Outcome |

|---|---|---|

| Hazard Assessment | Identify risks like impact, puncture, and slips. | Data-driven policy foundation. |

| Footwear Policy | Define mandatory safety features (ASTM standards). | Clear, enforceable safety rules. |

| Procurement & Fit | Establish purchasing guidelines and prioritize comfort. | Higher employee adoption and compliance. |

| Avoid Common Pitfalls | Involve employees and avoid a one-boot-fits-all approach. | A successful, sustainable program. |

Ready to build a best-in-class protective footwear program for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. We can provide the durable, compliant, and comfortable boots your program requires, from steel toes to metatarsal guards and slip-resistant soles.

Contact our experts today to discuss how we can support your hazard assessment and supply the right footwear for your workforce's safety and productivity.

Visual Guide

Related Products

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

People Also Ask

- Are work boots suitable for everyday use? The Ultimate Guide to Comfort & Durability

- What are moc toe boots known for? Unmatched Durability, Comfort & Timeless Style

- What features should a work boot have for a DIY mechanic? Essential Protection for Your Garage

- How have engineer boots influenced women's fashion? A Symbol of Rugged, Androgynous Style

- What are the benefits of easy-to-clean farming and gardening boots? Boost Efficiency, Safety & Durability

- What care tips are recommended for maintaining Clarks desert boots? Essential Guide for Leather & Suede

- In what environments can work boots be worn? From Heavy Industry to Casual Style

- What maintenance tips should be followed for farm boots? Extend Their Lifespan & Protect Your Feet