At its core, vulcanized shoe manufacturing is a process where a shoe's rubber sole components are chemically bonded to its upper using intense heat and pressure. Instead of just gluing or stitching a pre-molded sole, the entire shoe is "baked" in a specialized oven, fusing the raw rubber parts into a single, durable, and highly flexible unit.

The key to understanding vulcanized shoes lies in the manufacturing process itself. The heat-curing method is directly responsible for the shoe's defining characteristics: its superior flexibility and board feel, which come at the trade-off of reduced cushioning and long-term durability.

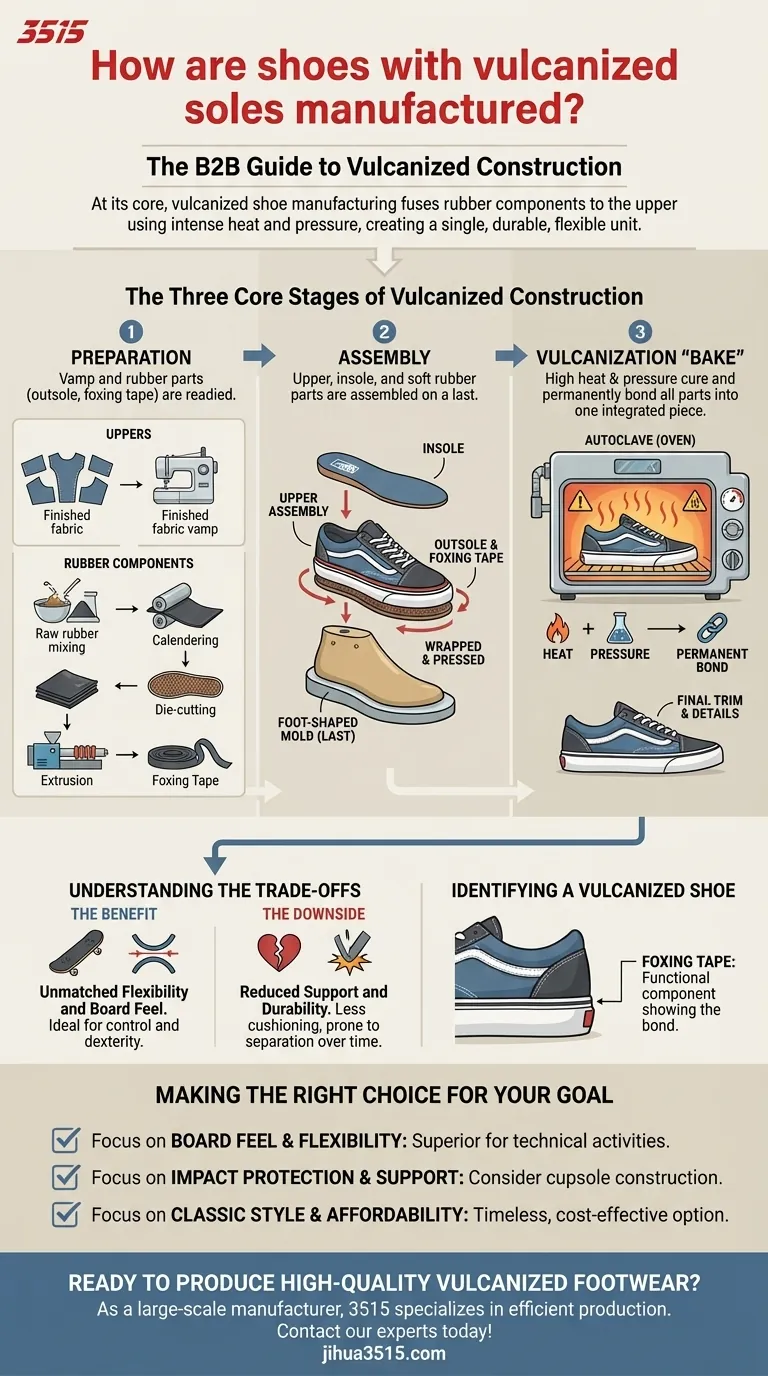

The Three Core Stages of Vulcanized Construction

The creation of a vulcanized shoe can be broken down into three distinct phases: component preparation, careful assembly, and the final heat-curing process that gives the shoe its name.

Stage 1: Preparing the Components

Before assembly, each part of the shoe must be created. The upper, or vamp, is typically made by die-cutting fabric panels and sewing them together according to the design.

Simultaneously, the rubber components are formed. Raw rubber is mixed, then rolled into sheets through a process called calendering. This sheet is then hot-pressed to create the outsole, while a separate process called extrusion forms the iconic rubber sidewall, known as foxing tape.

Stage 2: The Assembly Process

With the upper and rubber parts ready, the shoe is assembled on a foot-shaped mold called a last. The upper is stretched over the last to give it its shape.

An insole is glued in place. Then, the outsole and the crucial foxing tape are carefully wrapped and pressed onto the upper assembly. At this stage, the rubber is still relatively soft and gummy, held together only by a light adhesive.

Stage 3: The Vulcanization "Bake"

This is the defining step. The assembled shoe is placed into a vulcanizing oven, or autoclave, which applies both high pressure and high temperatures.

This "baking" process initiates a chemical change in the rubber. It cures the material, cross-linking its polymers to make it strong and elastic. Most importantly, it permanently bonds the outsole and foxing tape to the shoe's upper, creating one integrated piece. After cooling, the shoe gets a final trim and any last details are added.

Understanding the Trade-offs

The vulcanization method directly dictates the shoe's performance characteristics. This unique construction creates a distinct set of advantages and disadvantages.

The Benefit: Unmatched Flexibility and Board Feel

Because the sole is fused directly to the upper in a thin, single layer, the result is an exceptionally flexible shoe. For activities like skateboarding, this allows the wearer to have a much better feel for the board under their feet, enabling greater control.

The Downside: Reduced Support and Durability

The same minimalist construction that provides flexibility offers less structural support and impact cushioning. The simple, heat-fused bond is also more prone to separating over time with heavy wear compared to a stitched cupsole.

The Visual Cue: Identifying a Vulcanized Shoe

You can often identify a vulcanized shoe by its foxing tape. This strip of rubber runs level and flat around the entire perimeter of the shoe where the upper meets the sole. It isn't just a decorative bumper; it's a functional component of the manufacturing process.

Making the Right Choice for Your Goal

Understanding how a vulcanized shoe is made helps you choose footwear based on performance needs, not just aesthetics.

- If your primary focus is board feel and flexibility: The direct connection to the ground makes vulcanized construction the superior choice for technical skateboarding or activities requiring foot dexterity.

- If your primary focus is impact protection and all-day support: You may prefer a shoe with a cupsole construction, which provides more cushioning and a more structured foundation for your foot.

- If your primary focus is classic style and affordability: The relatively simple and efficient manufacturing process makes vulcanized shoes, like classic canvas sneakers, a timeless and cost-effective option.

By recognizing the engineering behind the shoe, you can confidently select the construction that is truly built for your purpose.

Summary Table:

| Stage | Key Process | Outcome |

|---|---|---|

| 1. Preparation | Calendering rubber sheets, cutting/sewing uppers | Ready-to-assemble components |

| 2. Assembly | Wrapping foxing tape and outsole onto the lasted upper | Pre-vulcanized shoe assembly |

| 3. Vulcanization | Baking in an autoclave under heat and pressure | Permanent bond creating a flexible, single-unit sole |

Ready to produce high-quality vulcanized footwear?

As a large-scale manufacturer, 3515 specializes in the efficient production of vulcanized shoes and boots. We offer comprehensive manufacturing services for distributors, brand owners, and bulk clients, ensuring durable construction and classic style.

Contact our experts today to discuss your production needs and leverage our full-range footwear capabilities.

Visual Guide

Related Products

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Wholesale Training Shoes with Dial Lacing System Custom OEM Manufacturing

- Wholesale Breathable Athletic Sneakers - Custom Lightweight Cushioned Footwear Manufacturer

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Durable Camouflage Canvas Shoes with High-Traction Cleated Rubber Sole

People Also Ask

- What is the importance of using high-precision anthropometric measurements in footwear development? Data Standardization

- What is the value of integrating heart rate monitoring and RPE in footwear evaluation? Optimize Athlete Performance

- What role does shock-absorbing cushioning play in preventing muscle fatigue? Boost Performance & Endurance

- How do precise anthropometric measurements influence Training Shoes? Optimize GMC Assessment Accuracy

- Why is specialized technical training required when operating advanced equipment for footwear circular materials?