At its core, the manufacturing process for Polyvinyl Chloride (PVC) wellington boots is defined by speed, efficiency, and simplicity. These boots are made using injection molding, a method where molten PVC plastic is forced into a boot-shaped mold under high pressure. The plastic then cools and solidifies, creating a single, seamless, and inherently waterproof boot.

The choice of injection molding is not just a manufacturing detail; it is the primary reason PVC wellingtons possess their signature traits. This process directly results in their affordability and flawless waterproofing but also introduces specific trade-offs in flexibility and long-term durability compared to other materials.

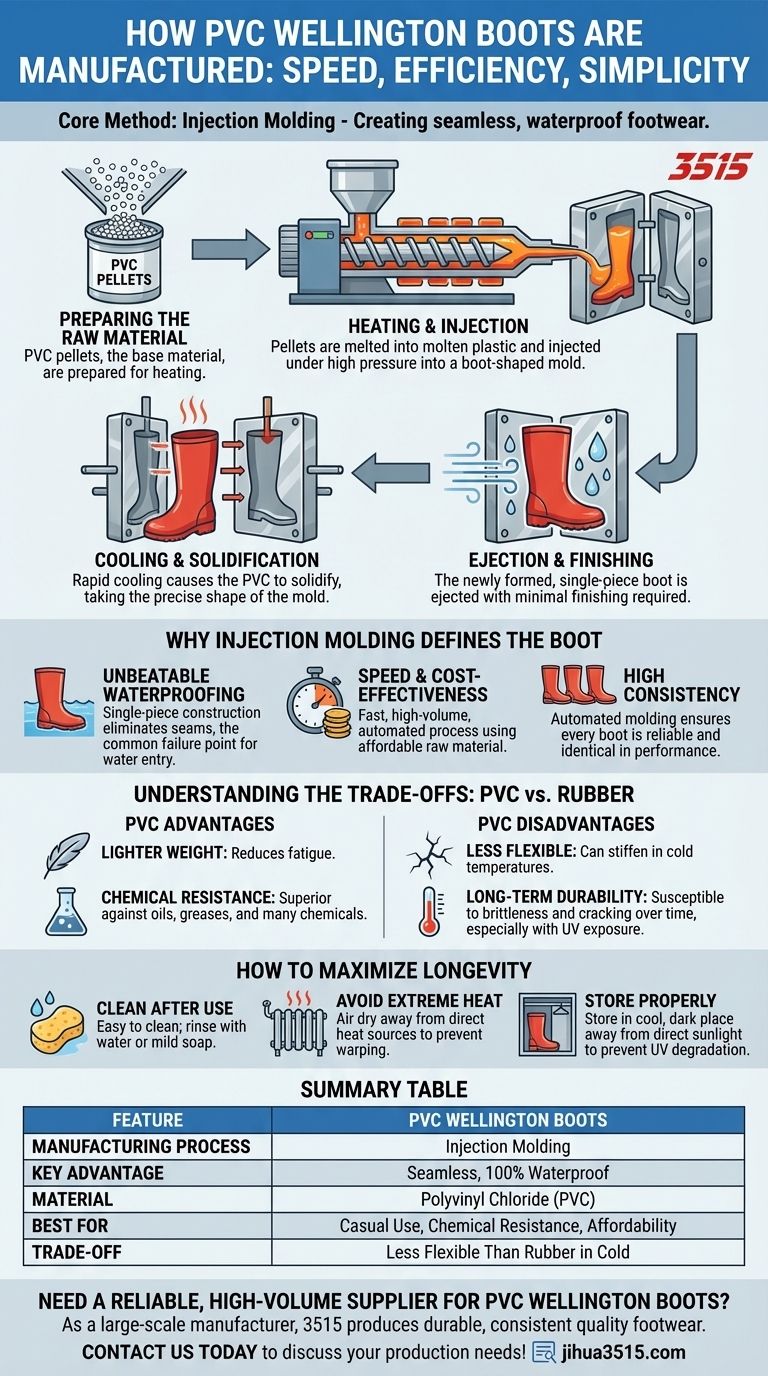

The Injection Molding Process: A Step-by-Step View

Understanding how a PVC boot is formed reveals why it behaves the way it does. The process is highly automated and can be broken down into a few key stages.

Preparing the Raw Material

The process begins with polyvinyl chloride in the form of small, solid pellets. These pellets are the base material that will be heated and shaped into the final product.

Heating and Injection

The PVC pellets are fed into an injection molding machine where they are heated until they become a molten, liquid plastic. This liquid is then injected under immense pressure into a precisely machined, two-part metal mold shaped like a boot.

Cooling and Solidification

Once the mold is filled, it is cooled rapidly. This causes the molten PVC to solidify, perfectly taking on the shape and details of the mold's interior.

Ejection and Finishing

After a short cooling period, the mold opens and the newly formed boot is ejected. Because the process creates a single, finished piece, minimal trimming or finishing is required, which further contributes to the speed and cost-effectiveness of production.

Why This Method Defines the Boot

The use of injection molding is fundamental to the value proposition of a PVC wellington. It is chosen specifically for the advantages it imparts to the final product.

Unbeatable Waterproofing

The single-piece construction created by injection molding eliminates seams. Seams are the most common failure point for water entry in other types of footwear, making a molded PVC boot a completely waterproof barrier by design.

Speed and Cost-Effectiveness

Injection molding is an extremely fast, high-volume manufacturing process. The combination of an affordable raw material (PVC) and an automated production cycle makes these boots one of the most economical waterproof footwear options available.

High Consistency

Automated molding ensures that every boot produced is virtually identical. This leads to reliable, predictable performance in terms of fit, durability, and waterproofing across thousands of units.

Understanding the Trade-offs: PVC vs. Rubber

While excellent for many applications, the material properties of PVC and its manufacturing process create important distinctions when compared to traditional natural rubber boots.

Advantage: Weight and Chemical Resistance

PVC is generally lighter than natural rubber, reducing fatigue during wear. It also offers exceptional resistance to a wide range of chemicals, oils, and greases, making it a superior choice for many industrial, agricultural, and cleaning applications.

Disadvantage: Flexibility and Comfort

PVC is typically a more rigid material than natural rubber. This can make the boots feel less flexible, especially in cold temperatures where the plastic can stiffen, potentially impacting all-day comfort for some users.

Disadvantage: Long-Term Durability

While durable for many uses, PVC can become brittle and susceptible to cracking over time, particularly with frequent flexing and exposure to UV light. High-quality natural rubber often maintains its flexibility and resists cracking for longer.

How to Maximize Longevity

Proper care is essential to getting the most out of your PVC boots and mitigating the material's inherent trade-offs.

Clean After Use

The smooth, non-porous surface of PVC makes it incredibly easy to clean. Simply remove excess dirt and rinse with water. For stubborn stains, a mild soap is sufficient.

Avoid Extreme Temperatures

Always air dry your boots away from direct heat sources like radiators, which can warp or damage the plastic.

Store Properly

Store your boots in a cool, dark place away from direct sunlight. Prolonged exposure to UV radiation is a primary cause of PVC degradation, leading to discoloration and brittleness.

Making the Right Choice for Your Goal

Selecting the right boot means matching its material characteristics to your intended use.

- If your primary focus is affordability and casual use: PVC is an excellent, lightweight, and waterproof choice for tasks like gardening, festivals, or occasional wet-weather walks.

- If your primary focus is work in an industrial or farm setting: PVC's superior resistance to chemicals, oils, and fats makes it a highly practical and safe choice.

- If your primary focus is frequent, heavy-duty outdoor use: Compare PVC with high-quality natural rubber boots, which may offer better long-term flexibility and crack resistance for demanding activities.

Ultimately, understanding how your boots are made allows you to choose the right tool for the job, ensuring your footwear performs exactly as you need it to.

Summary Table:

| Feature | PVC Wellington Boots |

|---|---|

| Manufacturing Process | Injection Molding |

| Key Advantage | Seamless, 100% Waterproof |

| Material | Polyvinyl Chloride (PVC) |

| Best For | Casual Use, Chemical Resistance, Affordability |

| Trade-off | Less Flexible Than Rubber in Cold Temperatures |

Need a reliable, high-volume supplier for PVC wellington boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our injection molding expertise ensures you receive durable, perfectly waterproof boots with consistent quality across every order.

Contact us today to discuss your production needs and get a competitive quote!

Visual Guide

Related Products

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

People Also Ask

- What are the benefits of rubber boots? Superior Waterproofing, Durability & Slip-Resistance

- What are the recommended materials for temporary or part-time workers needing waterproof boots? Find the Most Cost-Effective Choice

- What should you do if wellies become wet inside? The Safe, 3-Step Guide to Dry Boots Fast

- What are the characteristics of rain boots? A Guide to Waterproof Footwear for Every Need

- How can the lifespan of natural rubber boots be prolonged? A Guide to Proper Cleaning and Conditioning

- What are the main drawbacks of traditional wellingtons for extended use? Find Your Perfect Fit

- What factors should be considered when choosing wellington boots for different activities? A Guide to Material, Support, and Endurance

- What are the main materials for waterproof rain boots? Choose the Right Material for Durability & Comfort