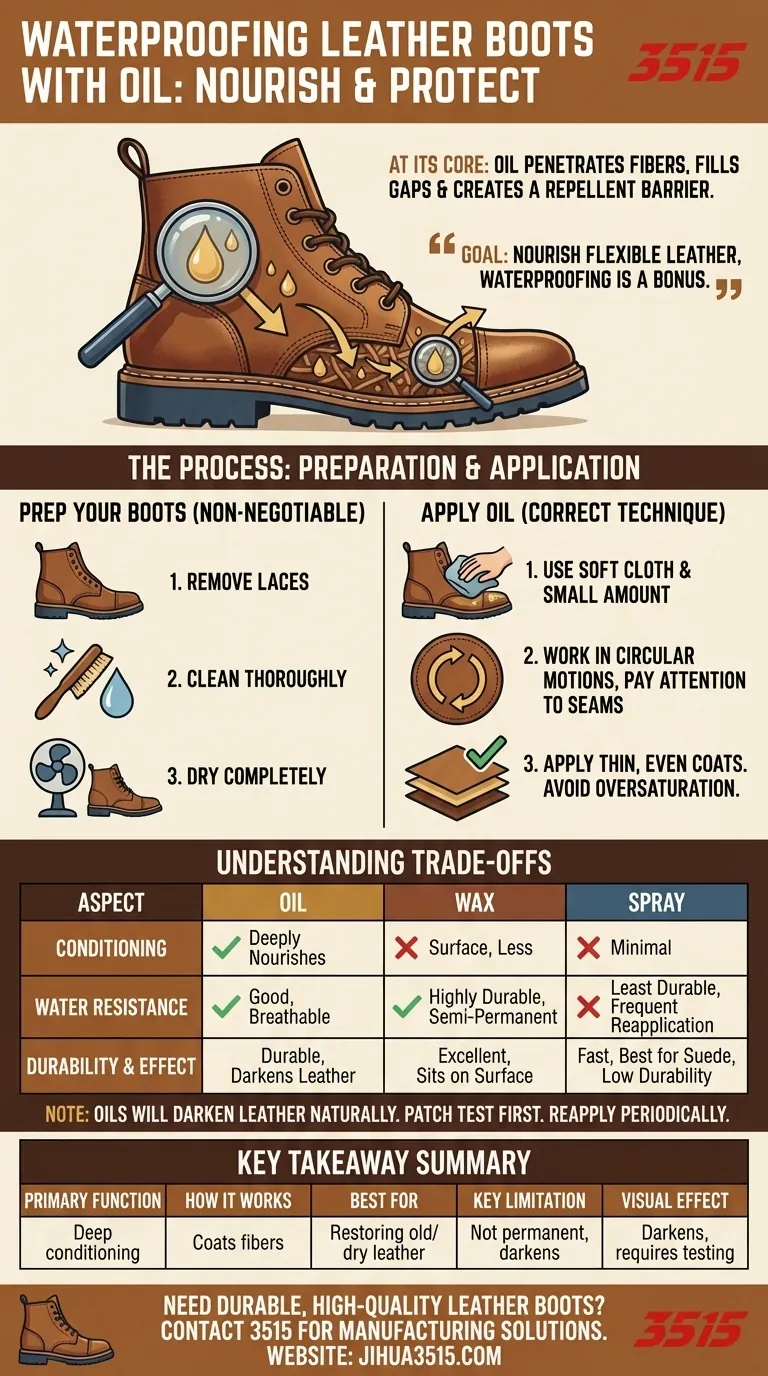

At its core, waterproofing leather boots with oil involves applying a product like mink or neatsfoot oil directly onto clean leather. The oil penetrates the leather's porous fibers, filling the microscopic gaps and creating a barrier that repels water. This process not only provides water resistance but also conditions and moisturizes the leather, preventing it from drying out and cracking.

The real goal isn't just to block water, but to nourish the leather itself. While oils provide a good level of water resistance, their primary function is to keep the leather flexible and healthy, with waterproofing being a beneficial side effect of that conditioning.

The Role of Oil in Leather Care

Leather is a natural material, a skin, and it requires moisture to remain supple. Oils serve as a conditioning agent that restores the natural fats lost over time and through exposure to the elements.

How Oiling Creates Water Resistance

Leather contains countless microscopic pores. When you apply oil, it soaks into these pores and coats the individual fibers. This coating doesn't let water molecules easily pass through, forcing them to bead up and roll off the surface instead.

The Conditioning Benefit

Beyond just repelling water, oils are critical for maintaining the leather's health. Dry, brittle leather is prone to cracking, especially at flex points like the ankle and toe box. Oiling replenishes these essential fats, keeping the material strong and pliable.

Preparing Your Boots for Oiling

Proper preparation is non-negotiable for an effective treatment.

- Remove Laces: Take out the laces to ensure you can access the entire tongue and all eyelet areas.

- Clean Thoroughly: Use a brush to remove all loose dirt and mud. For a deeper clean, use a dedicated leather cleaner to remove any embedded grime that could get sealed in by the oil.

- Dry Completely: The boots must be completely dry before you apply any product. Stuffing them with newspaper or using a fan can help, but avoid direct heat sources like radiators, as this can damage the leather.

Applying Oil: The Correct Technique

The application process is straightforward but requires attention to detail to avoid damaging the leather.

Use a Soft, Clean Cloth

Apply a small amount of oil to a clean, lint-free cloth. Do not apply the oil directly to the boot, as this can lead to over-saturation in one spot.

Work in Circular Motions

Gently massage the oil into the leather using small, circular motions. This helps ensure an even distribution and promotes absorption. Pay special attention to seams, creases, and the welt (where the upper meets the sole), as these are common failure points for water entry.

Apply Thin, Even Coats

It's better to apply two thin coats than one thick, heavy coat. A single, oversaturated application can make the leather feel greasy, attract dirt, and can even weaken its fibrous structure over time.

Understanding the Trade-offs

Using oil is an excellent traditional method, but it's important to be aware of its specific characteristics and limitations compared to other waterproofing products.

Oil vs. Wax

Oils penetrate deeply to condition the leather from within, offering good water resistance and excellent flexibility. Waxes, on the other hand, sit more on the surface to create a highly durable, semi-permanent waterproof seal but offer less conditioning.

Oil vs. Sprays

Oils provide more durable protection and actively nourish the leather. Spray-on treatments are fast and easy to apply but offer the least durable protection, wearing off quickly and requiring frequent reapplication. They are often better suited for materials like suede that can be damaged by heavy oils or waxes.

The Inevitable Darkening

Nearly all conditioning oils will darken the color of your leather. This is a natural part of the process. Always perform a small patch test on an inconspicuous area, like the inner side of the boot's tongue, to see how the leather will react before treating the entire boot.

Reapplication is Key

Oil-based water resistance is not permanent. You will need to reapply the treatment periodically, typically every month or so with regular use, or any time after the boots have been significantly soaked.

Making the Right Choice for Your Goal

Your choice of waterproofing method depends on your boots and your priorities.

- If your primary focus is deep conditioning and restoring older, dry leather: Oil is the superior choice for replenishing moisture and flexibility while providing solid water resistance.

- If your primary focus is creating the most durable, long-lasting waterproof barrier for heavy use: A hard boot wax applied over a lightly oiled base will provide the most robust protection.

- If your primary focus is quick, convenient water resistance for casual use or on sensitive materials: A spray-on treatment is the fastest and easiest option, but be prepared for frequent reapplication.

Ultimately, proper boot care is a cycle of cleaning, conditioning, and protecting that ensures your investment lasts for years to come.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Primary Function | Deeply conditions leather to maintain flexibility and health; water resistance is a beneficial side effect. |

| How It Works | Oil penetrates leather's pores, coating fibers to repel water molecules. |

| Best For | Restoring and maintaining the health of dry, older leather boots. |

| Key Limitation | Not a permanent seal; requires reapplication (typically monthly with regular use). |

| Visual Effect | Darkens leather color; a patch test is recommended. |

Need Durable, High-Quality Leather Boots to Protect?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of durable shoes and boots, built to last with proper care.

Let us help you equip your customers with reliable footwear.

Contact us today to discuss your manufacturing needs and how we can bring value to your supply chain.

Visual Guide

Related Products

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What role does an Ultra-Wideband (UWB) wireless ranging module play in decentralized cooperative positioning? Boost Accuracy

- How does FEA contribute to footwear stiffness and strength? Precision Engineering for High-Performance Shoes

- How do industrial-grade waste management systems optimize the footwear production process? Boost Your Factory Efficiency

- When might someone need prescription orthotics? Key Signs OTC Inserts Aren't Enough

- What factors should be considered when choosing footwear for different activities? Maximize Performance & Safety

- How does water utilization efficiency impact footwear manufacturing sustainability? Optimize Your Industrial Design

- What technical support does 3D virtual fitting software provide? Enhancing Footwear & Apparel Ergonomic Design

- Why is business casual attire considered tricky to define? Navigating the Ambiguous Dress Code