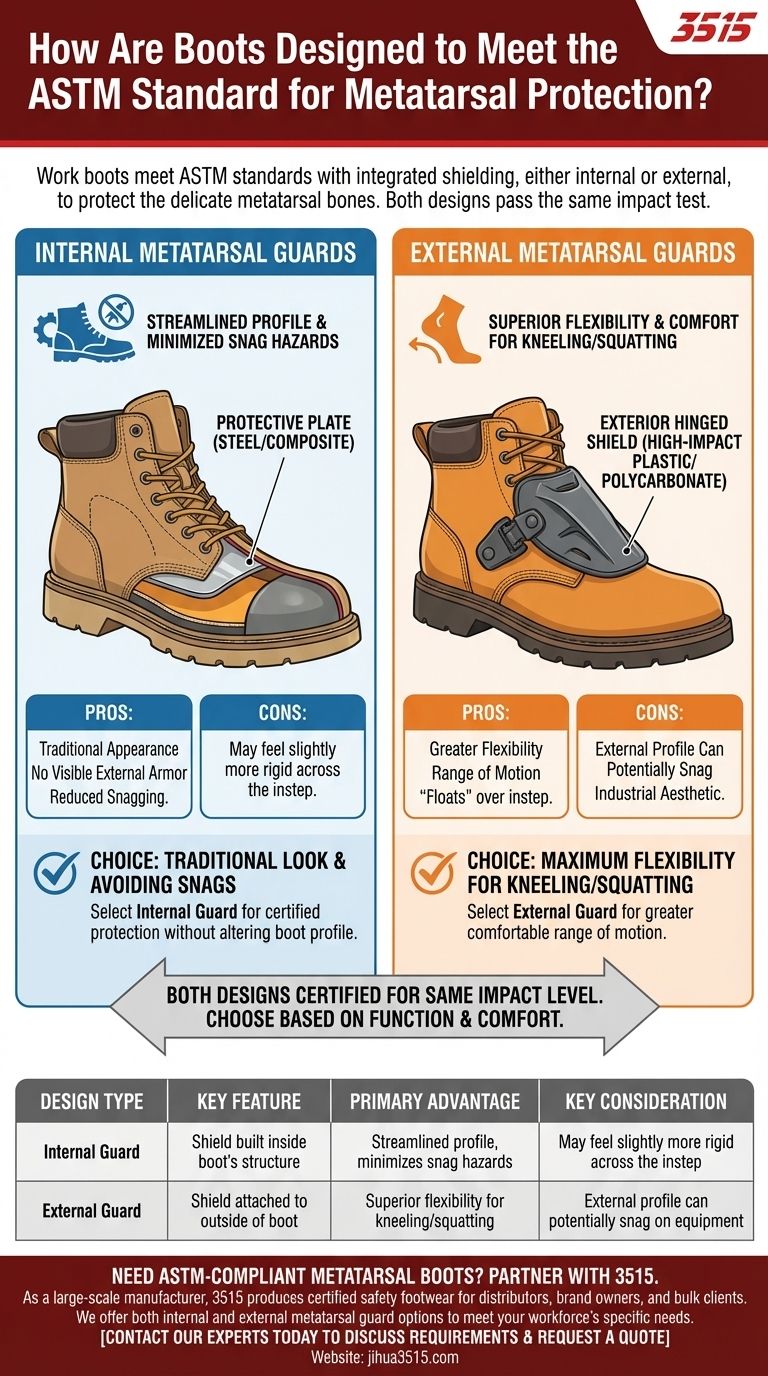

To meet the ASTM standard for metatarsal protection, work boots are designed with integrated shielding over the top of the foot, where the delicate metatarsal bones are located. This is accomplished using one of two primary design philosophies: an internal guard built into the boot's structure or an external guard affixed to the outside of the boot.

The core difference isn't about which design is "safer"—as both must pass the same ASTM impact test—but about the trade-offs between a streamlined look, flexibility, and potential snag hazards in your work environment.

The Two Core Designs for Metatarsal Protection

The ASTM F2413 standard for metatarsal (Mt) protection sets a performance benchmark, not a specific design mandate. It ensures a boot can withstand a significant impact and compression load, leaving manufacturers to innovate on the best way to achieve that protection. This has led to two distinct and effective approaches.

Internal Metatarsal Guards

An internal metatarsal guard is a protective plate made from materials like steel, aluminum, or composite materials that is built directly into the boot.

This shield sits between the inner lining and the outer material of the boot, right above the wearer's instep.

Because it is integrated, the boot maintains a traditional appearance, with no visible external armor. This design is often preferred for its clean look and for minimizing snag hazards.

External Metatarsal Guards

An external metatarsal guard is a protective shield that is attached to the outside of the boot, typically hinged over the laces.

This exterior shield is often made from durable materials like high-impact plastic or polycarbonate.

The external design allows the guard to "float" over the instep, which can provide greater flexibility when crouching or bending the foot. Its visible, rugged appearance makes its protective nature immediately obvious.

Understanding the Trade-offs

While both designs are certified to protect you from the same level of impact, their construction creates different user experiences and functional advantages. Choosing the right one depends on your specific job tasks and personal preferences.

Pros and Cons of Internal Guards

The main advantage of an internal guard is its streamlined profile. The boot looks and feels more like a standard work boot, which prevents the shield from catching on machinery, debris, or other environmental hazards.

However, because the guard is a fixed part of the boot's structure, some users may find it slightly more rigid or less flexible across the top of the foot.

Pros and Cons of External Guards

External guards are often praised for their superior flexibility. Because the shield is hinged and sits outside the boot, it can move more freely as the foot bends, making it more comfortable for jobs that require frequent kneeling or squatting.

The primary drawback is the external profile. The visible shield can potentially snag on equipment or materials, and its industrial aesthetic may not be suitable for all roles.

Making the Right Choice for Your Goal

Your decision should be based on the practical realities of your workday. Both internal and external metatarsal boots are certified to protect you, so the choice comes down to function and comfort.

- If your primary focus is a traditional boot appearance and avoiding snag hazards: An internal metatarsal guard provides certified protection without altering the boot's profile.

- If your primary focus is maximum flexibility for frequent kneeling or squatting: An external guard often allows for a greater and more comfortable range of motion.

- If your primary focus is simply meeting a site's safety requirement: Both designs are equally compliant with the ASTM standard, so you can choose based on personal comfort and the specific tasks you perform.

Understanding these design differences allows you to select a boot that provides certified protection without compromising the comfort and mobility your job demands.

Summary Table:

| Design Type | Key Feature | Primary Advantage | Key Consideration |

|---|---|---|---|

| Internal Guard | Shield built inside the boot's structure | Streamlined profile, minimizes snag hazards | May feel slightly more rigid across the instep |

| External Guard | Shield attached to the outside of the boot | Superior flexibility for kneeling/squatting | External profile can potentially snag on equipment |

Need ASTM-Compliant Metatarsal Boots for Your Team? Partner with 3515.

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Whether your workforce requires the streamlined protection of an internal guard or the enhanced flexibility of an external design, our production capabilities encompass all types of safety boots and shoes.

Let us help you equip your team with the right protection for their specific job demands. Contact our experts today to discuss your requirements and request a quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Suede Metatarsal Guard Safety Boots Work Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Durable Safety Boots | Custom Steel Toe & Puncture-Resistant Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- What do heavy duty boots do? Protect Your Feet in Demanding Work Environments

- Is safety-toe as good as steel toe? Choose the Right Protection for Your Job

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- Do snake bite boots work? Your Ultimate Guide to Effective Snake Bite Protection

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management