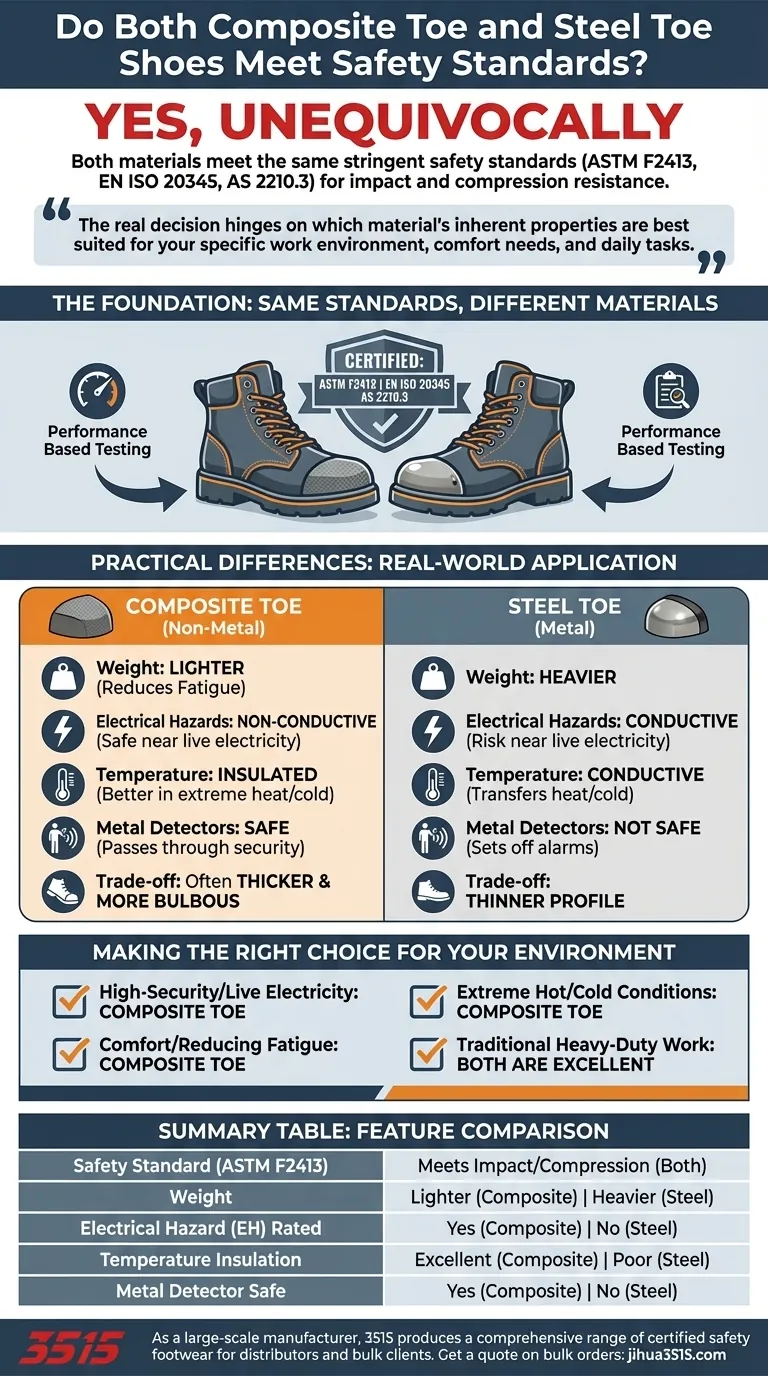

Yes, unequivocally. Both composite toe and steel toe footwear are designed to meet the same stringent safety standards for impact and compression resistance. The key is that the certification is based on performance in standardized tests, not the material used to construct the protective toe cap.

The question is not whether one type is "safer" than the other, as both must pass the same foundational safety tests. The real decision hinges on which material's inherent properties are best suited for your specific work environment, comfort needs, and daily tasks.

The Foundation: Understanding Safety Standards

At the core of safety footwear certification are standards that ensure a boot can protect your feet from specific, measurable hazards. Both composite and steel toe boots are held to these exact same benchmarks.

What the Standards Guarantee

The most prominent standard in the United States is ASTM F2413. This certification guarantees that the protective toe cap in a boot—regardless of material—has been tested to withstand a specific level of impact and compression.

Key Certifications to Look For

While ASTM is the American standard, you will see equivalent certifications globally. These include EN ISO 20345 (European) and AS 2210.3 (Australian/New Zealand). If a boot carries these ratings, it has passed the required performance tests.

It's About Performance, Not Material

Safety organizations like ASTM and OSHA approve footwear based on its ability to pass objective tests. A composite toe must withstand the same 75-pound drop test (impact) and 2,500 pounds of pressure (compression) as a steel toe to earn the same rating.

Practical Differences Beyond the Standard

While both materials achieve the same safety rating, their inherent properties create significant practical differences in the real world. Understanding these is crucial for making the right choice.

Weight and Comfort

Composite toe caps are made from non-metal materials like carbon fiber, Kevlar, or plastic. This makes them significantly lighter than steel toe caps, which can reduce foot fatigue over a long workday.

Electrical Hazards (EH)

Because they contain no metal, composite toes are non-conductive. This makes them the superior choice for electricians or anyone working in environments where contact with live electrical circuits is a risk.

Temperature and Climate

Steel is a highly conductive material. It will get very cold in winter and hot in the summer, transferring that temperature to your feet. Composite materials do not conduct heat or cold, offering much better insulation in extreme weather.

Working with Metal Detectors

For professionals in fields like security, aviation, or high-security facilities, a key benefit of composite toe footwear is that it will not set off metal detectors. This eliminates a common daily hassle.

Understanding the Trade-offs

Neither material is perfect for every situation. Being aware of the potential downsides is just as important as knowing the benefits.

The Bulk Factor (Composite)

To achieve the same strength rating as a thin piece of steel, composite toe caps often need to be thicker and more bulbous. This can sometimes make the boot feel slightly larger or bulkier at the tip.

The Conductivity Factor (Steel)

As mentioned, steel's primary drawback is its conductivity of both electricity and temperature. In environments where these are a concern, steel is a clear disadvantage.

Response to Extreme Impact

Both materials pass the ASTM standard. However, they behave differently under forces that exceed that standard. Steel tends to bend and can potentially trap the foot, while composite materials are more likely to crack or shatter upon catastrophic failure.

Making the Right Choice for Your Environment

Your specific job site and daily tasks should be the final deciding factor.

- If your primary focus is working in high-security areas or around live electricity: Composite toe is the definitive choice for its non-metallic and non-conductive properties.

- If your primary focus is comfort and reducing fatigue over long shifts: The lighter weight of composite toe boots provides a significant advantage.

- If your primary focus is working in extreme hot or cold conditions: Composite toe offers superior insulation and will not transfer ambient temperatures.

- If your primary focus is traditional heavy-duty work without specific electrical or security needs: Both are excellent options, and the choice can be made based on personal preference for fit and comfort.

Ultimately, the best choice is not about which material is safer, but which one's properties best align with the specific demands of your workday.

Summary Table:

| Feature | Composite Toe | Steel Toe |

|---|---|---|

| Safety Standard (ASTM F2413) | Meets Impact/Compression | Meets Impact/Compression |

| Weight | Lighter | Heavier |

| Electrical Hazard (EH) Rated | Yes (Non-conductive) | No (Conductive) |

| Temperature Insulation | Excellent | Poor (Conductive) |

| Metal Detector Safe | Yes | No |

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Whether your team needs the lightweight, non-conductive advantage of composite toe boots or the traditional durability of steel toe, our production capabilities ensure you get the right safety solution for your specific work environment.

Get a quote on bulk orders tailored to your needs — Contact our team today to discuss your requirements!

Visual Guide

Related Products

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

People Also Ask

- What are the two safety standards for steel cap boots in Australia and New Zealand? Choose the Right Protection

- How do safety toes and steel toes compare? Choose the right protection for mobility or durability.

- How do steel toe boots compare to composite toe boots in terms of protection? A Guide to Maximum Safety & Comfort

- When should you seek professional help for foot pain caused by steel toe boots? Recognize the Warning Signs

- Why do landscapers need steel-toe boots? Essential Protection for a Hazardous Job

- What type of safety toe is recommended for hunting boots? Choose the Right Toe for Your Hunt

- What are steel-toe boots and why are they important? Essential Foot Protection for High-Risk Work

- What does OSHA say about steel toe boots? A Guide to Compliant Footwear