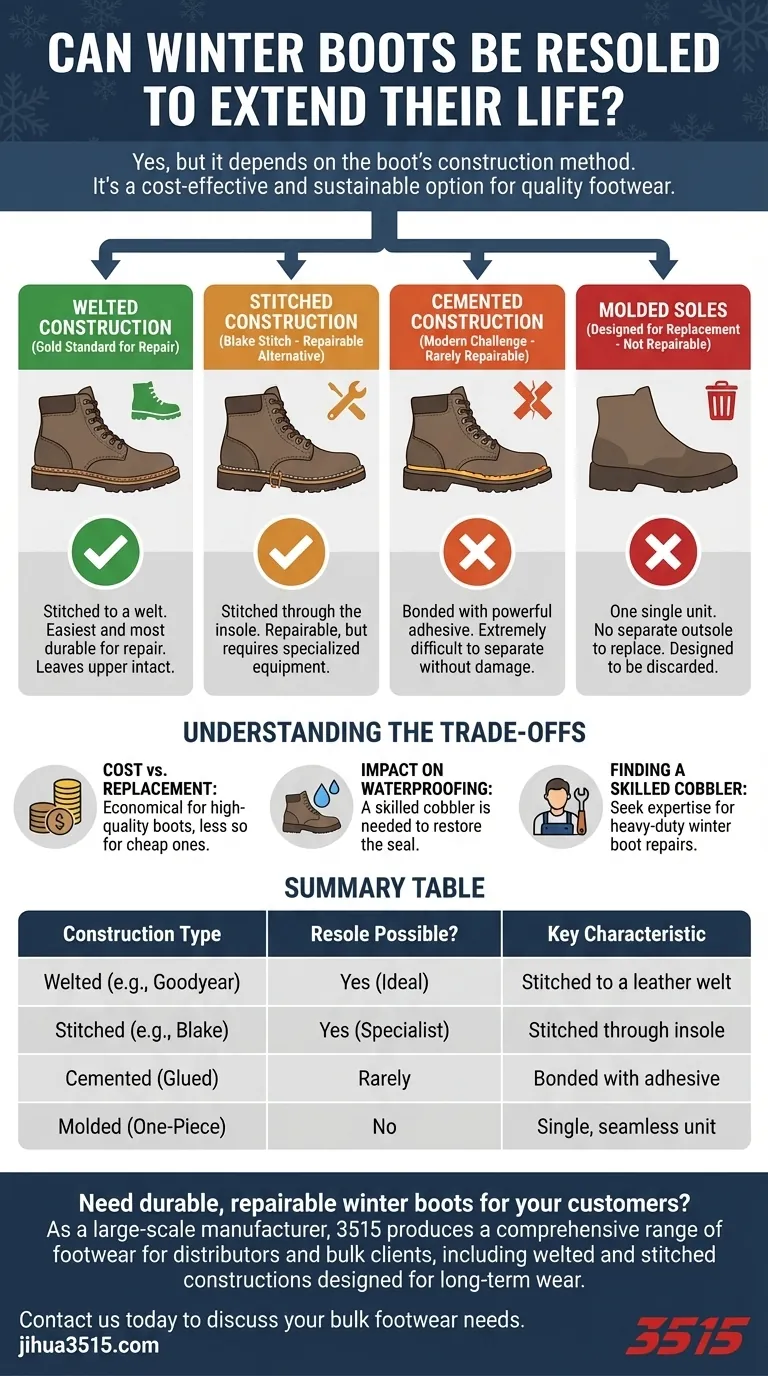

Yes, in many cases, winter boots can be resoled to extend their life. This is often a cost-effective and sustainable way to keep a comfortable, broken-in pair of boots in service. However, the ability to resole a boot is not determined by its style or brand, but by its fundamental construction method.

The critical factor determining if a winter boot can be resoled is how the sole was originally attached to the upper part of the boot. Welted and stitched constructions are designed for repair, while cemented or molded soles often are not.

Why Construction Method is Everything

To understand if your boots are a candidate for repair, you first need to understand how they were made. The manufacturing technique dictates whether a cobbler can cleanly remove the old sole without destroying the rest of the boot.

Welted Construction: The Gold Standard for Repair

The most durable and repair-friendly method is a welted construction, such as a Goodyear welt. In this process, a strip of leather (the welt) is stitched to the boot's upper, and the outsole is then stitched to the welt.

This design creates a robust, water-resistant buffer between the insole and the outsole. Crucially, it allows a cobbler to remove and replace the sole by simply cutting the stitches on the welt, leaving the upper completely intact.

Stitched Construction: A Repairable Alternative

Another common method is a Blake stitch, where the outsole is stitched directly through to the insole and the upper.

Boots with this construction can still be resoled. However, it requires a specialized Blake stitching machine that not every cobbler has. Because the stitching penetrates the inside of the boot, it can be slightly less water-resistant than a true welt.

Cemented Construction: The Modern Challenge

The vast majority of modern, lightweight boots use cemented construction. The sole is attached directly to the upper using a powerful, permanent adhesive.

While this method is efficient and cost-effective for manufacturers, it makes resoling extremely difficult. Attempting to pry the old sole off often tears away parts of the upper, making a successful repair impossible or impractical.

Molded Soles: Designed for Replacement

Some winter boots, particularly lighter-duty or "pac" style boots, feature a molded sole. Here, the outsole and the lower portion of the upper are a single, seamless piece of rubber or synthetic material.

These boots cannot be resoled because there is no separate outsole to replace. They are designed to be discarded once the tread wears down.

Understanding the Trade-offs

Even if your boots are technically resolvable, you must consider the practical implications before proceeding. A successful resole depends on more than just the boot's construction.

Cost vs. Replacement

A professional resole is a skilled service and has a cost. It is most economical for high-quality, expensive boots where the repair cost is a fraction of buying a new pair. For an inexpensive, cemented boot, the cost of a complex repair could easily exceed its replacement value.

Impact on Waterproofing

Resoling a boot involves breaking its original factory seal. A skilled cobbler will use the correct adhesives and sealants to restore water resistance, but it's a critical step that must be done correctly. This is especially important for winter boots where keeping dry is a primary function.

Finding a Skilled Cobbler

Not all shoe repair shops are equipped for the heavy-duty work required for winter boots. Welted and stitched boots, in particular, require specific tools and expertise. Always seek out a reputable cobbler with experience in repairing rugged footwear.

Making the Right Choice for Your Boots

To determine if resoling is the right path, first identify your boot's construction and then consider your primary goal.

- If your primary focus is extending the life of a high-quality, expensive boot: Resoling is almost always the most economical and sustainable choice, provided it was built with a welted or stitched construction.

- If your primary focus is repairing a modern, lightweight boot with a glued sole: It is likely not possible or cost-effective to resole, and replacement is often the only practical option.

- If you are unsure about your boot's construction: The best course of action is to take it to a professional cobbler for an expert assessment before making any decision.

Knowing how your boots were made is the key to making an informed decision that can save you money and preserve a trusted pair of footwear for years to come.

Summary Table:

| Construction Type | Resole Possible? | Key Characteristic |

|---|---|---|

| Welted (e.g., Goodyear) | Yes (Ideal) | Sole stitched to a leather welt; easiest to repair. |

| Stitched (e.g., Blake) | Yes (Specialist required) | Sole stitched directly through the insole. |

| Cemented (Glued) | Rarely | Sole bonded with permanent adhesive; difficult to separate. |

| Molded (One-Piece) | No | Sole and lower upper are a single, seamless unit. |

Need durable, repairable winter boots for your customers?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of durable, welted, and stitched boots designed for long-term wear and easy resoling, ensuring your customers get the best value.

Contact us today to discuss your bulk footwear needs and explore our robust manufacturing solutions.

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- Why are safety boots with steel toes mandatory for logging? Ultimate Protection Against Heavy Impact Hazards

- What role do industrial safety shoes with steel toes or composite protective layers play in high-risk manufacturing?

- What is a safety-toe in a boot? Your Guide to Choosing the Right Protection

- Why do operations involving heavy fruit bunches and 'gancu' require anti-smash and anti-puncture safety boots?

- Are safety toe options available for women's work boots? A Guide to Steel, Composite & Alloy Toes