No, you cannot. Any composite toe safety shoe that has sustained a significant impact or compression event must be retired from service and replaced immediately. Even if the shoe shows no visible damage, its internal structure has been compromised, and it will not provide the required protection against a future accident.

The core principle of safety footwear is that it is designed for a single, significant protective event. Much like a motorcycle helmet or a car's airbag, its purpose is to sacrifice its own structural integrity to protect you once.

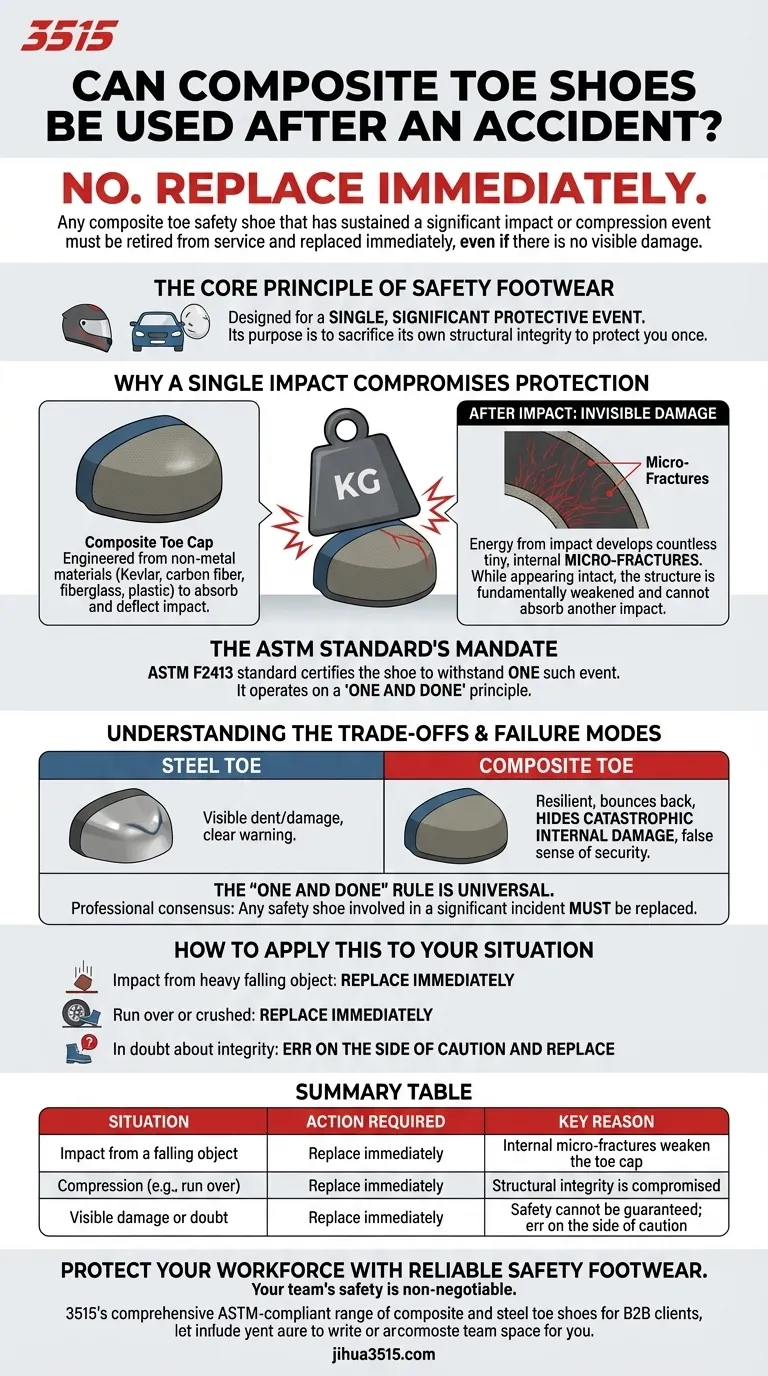

Why a Single Impact Compromises Protection

To understand why replacement is mandatory, you need to look beyond the surface and consider the material science behind the composite toe cap.

The Role of the Composite Toe Cap

A composite toe cap is engineered from non-metal materials like Kevlar, carbon fiber, fiberglass, or plastic. Its primary job is to absorb and deflect the energy from an impact or compression force, preventing that force from crushing your toes.

Micro-Fractures: The Invisible Damage

When a composite toe cap takes a heavy hit, it absorbs the energy by developing countless tiny, internal micro-fractures. These cracks are often invisible to the naked eye.

While the cap may appear intact, these fractures have fundamentally weakened its structure. It has done its job successfully, but its ability to absorb another impact is now gone.

The ASTM Standard's Mandate

Safety footwear in the United States is rated against the ASTM F2413 standard. This standard specifies performance requirements for impact and compression resistance.

Crucially, the testing certifies that the shoe can withstand one such event. It does not certify the footwear for repeated impacts. The standard implicitly operates on a "one and done" principle.

Understanding the Trade-offs

The rule of replacing footwear after an incident applies to all safety toes, but the failure mode of composite materials makes it especially critical.

The Difference in Failure Mode

A steel toe cap might bend or dent under a severe impact. While it must also be replaced, the damage is often visible, serving as a clear warning.

A composite toe, however, is designed to be resilient and bounce back to its original shape. It can hide the catastrophic internal damage, giving you a false sense of security. It will not reliably protect you a second time.

The "One and Done" Rule is Universal

Regardless of the material, the professional safety consensus is absolute: any safety shoe or boot involved in a significant impact or compression incident must be replaced.

Trusting your safety to footwear that has already been compromised is an unacceptable risk. The integrity of the materials can no longer be guaranteed.

How to Apply This to Your Situation

Your personal safety is not an area where you should take chances. The cost of a new pair of boots is insignificant compared to the cost of a debilitating foot injury.

- If your footwear has been struck by a heavy falling object: You must replace your shoes immediately, even if they look perfectly fine.

- If your footwear has been run over or crushed: You must replace your shoes immediately. The compression has created the same invisible micro-fractures.

- If you are ever in doubt about the integrity of your safety shoes: Err on the side of caution and replace them.

Your safety footwear is a critical piece of personal protective equipment designed to fail in a specific way to protect you—do not ask it to do its job twice.

Summary Table:

| Situation | Action Required | Key Reason |

|---|---|---|

| Impact from a falling object | Replace immediately | Internal micro-fractures weaken the toe cap |

| Compression (e.g., run over) | Replace immediately | Structural integrity is compromised |

| Visible damage or doubt | Replace immediately | Safety cannot be guaranteed; err on the side of caution |

Protect Your Workforce with Reliable Safety Footwear

Your team's safety is non-negotiable. As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-compliant safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of composite and steel toe shoes and boots, engineered for maximum protection and durability.

Don't compromise on safety. Ensure your workers have the reliable, certified protection they need.

Contact 3515 today to discuss your safety footwear requirements and secure your supply of high-quality, dependable PPE.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- Why are safety shoes considered a core identification target in industrial monitoring? Boosting AI Compliance

- How should employees contribute to safety shoe effectiveness? A Guide to Active Ownership

- What core features are required in high-performance safety shoes? Gear for Extreme Heat & Complex Environments

- Why are leather fire boots preferred for maneuverability? Lighter Weight for Superior Agility

- What are the pros and cons of artificial leather in motorcycle boots? Choose the Right Material for Your Ride

- What is the function of the ergonomic curve design in professional nursing safety shoes? Enhance Comfort & Foot Health

- What is the primary function of industrial safety shoes? Protect Feet from Heavy Impact & Crush Hazards

- What are the key considerations for choosing work shoes for warehouse employees? Prioritize Safety, Comfort & Durability