An operator is miles from base, the temperature plummeting. A critical ascent on snowshoes grinds to a halt. It’s not contact, but a equipment failure: a binding strap has snapped. The boot, despite being a top-tier model, had just enough "play" to create microscopic stress points on the strap with every step, until the frozen plastic finally gave way.

For the procurement manager who selected that gear or the brand that put its name on it, this single point of failure raises a costly question: what really went wrong?

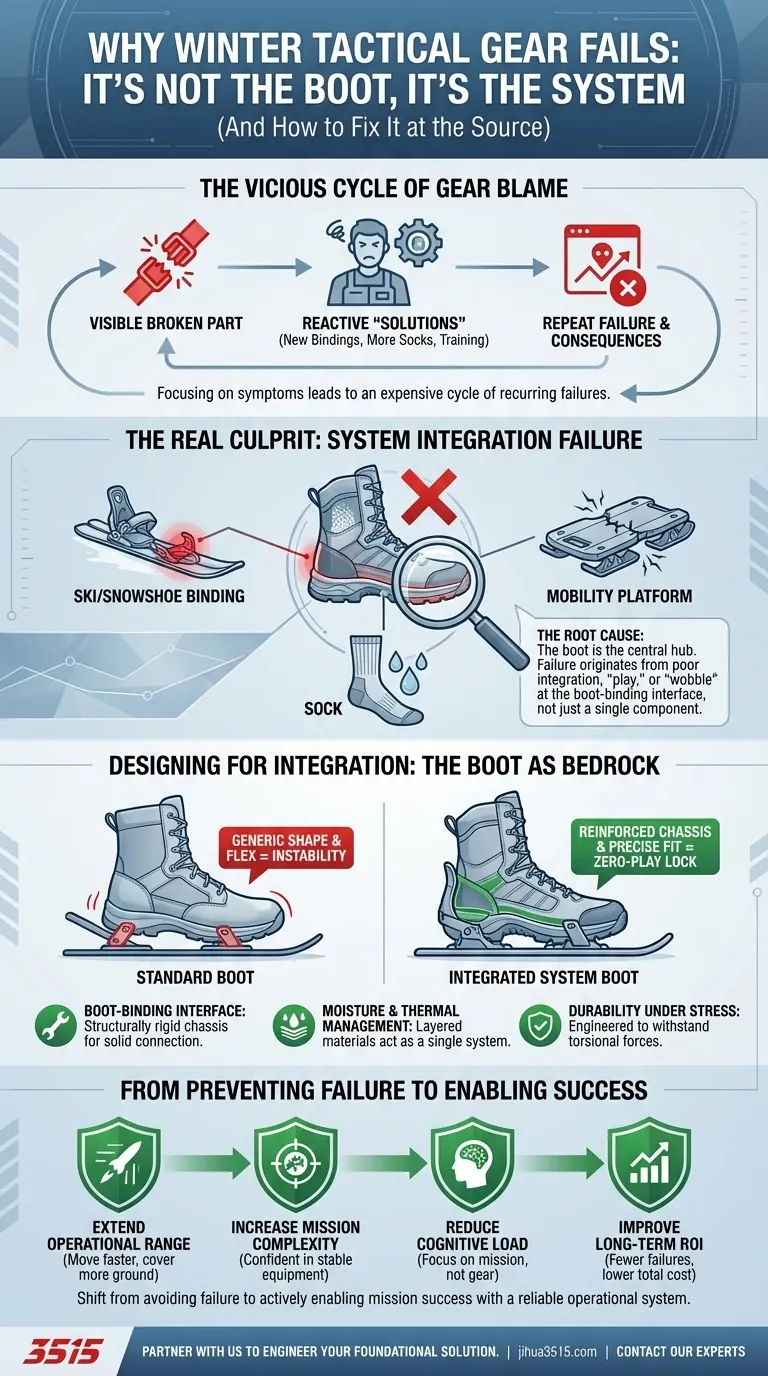

The Vicious Cycle of Gear Blame

This scenario is far too common. When winter mobility systems fail, the blame game begins. We instinctively focus on the most visible broken part:

- "The binding must have been faulty. We need to source a different model."

- "The operator’s feet were cold and wet. We need to issue thicker socks."

- "They didn't tighten the straps enough. We need more training."

While well-intentioned, these "solutions" are merely reactions to symptoms. Teams find themselves in a frustrating and expensive cycle: buying new ancillary gear, adding more training protocols, yet still experiencing the same unpredictable failures in the field.

The business consequences are severe. For brand owners, it means a damaged reputation. For distributors, it leads to customer complaints and costly returns. For government and private organizations, it results in compromised missions, increased risk to personnel, and a poor return on investment for the entire equipment outlay.

The Real Culprit: A Failure of System Integration

Here is the turning point: The problem is rarely a single faulty component. It is a system integration failure, and its origin point is almost always the boot.

A tactical boot is not just footwear. In a winter environment, it becomes the central hub connecting the operator to their mobility platform (skis or snowshoes). The effectiveness of the entire system—the sock, the boot, the binding, and the platform—is dictated by how well these parts work together.

The source article correctly identifies the need for a "zero play or wobble" fit. But it misses a crucial point: no amount of strap-tightening can fix a boot that was not fundamentally designed to create a secure lock-up with a universal binding.

This is why the common "solutions" fail:

- New Bindings: Attaching a high-quality binding to a boot with a soft, rounded toe box or flexible sole is like putting high-performance tires on a car with a broken axle. The foundation itself is unstable.

- Better Socks: The most advanced merino wool socks are rendered useless if the boot's materials don't breathe, trapping moisture and creating a microclimate for frostbite.

- More Training: You cannot train an operator to compensate for the inherent geometric incompatibility between their boot and binding.

The root of the problem is procuring boots based on isolated features (e.g., insulation, waterproofing) without considering its primary role as a systems integrator.

Designing for Integration: The Boot as the Bedrock of Your Mobility Platform

To truly solve this problem, you must shift your perspective. You don’t just need a "good boot"; you need a boot designed from the ground up to be the stable core of a winter mobility system.

This design philosophy is what separates a standard winter boot from a true tactical mobility platform. It requires engineering that specifically addresses the points of system failure:

- The Boot-Binding Interface: Instead of a generic shape, a boot designed for system integration features a reinforced, structurally rigid chassis. Key contact points at the toe and heel are shaped to mate precisely with universal bindings, ensuring a solid, "zero-play" connection is achievable and maintainable under load.

- Moisture and Thermal Management: An integrated design considers the boot and sock as a single system. It utilizes advanced, layered materials that work with moisture-wicking socks to actively pull sweat away from the skin and out of the boot, keeping the foot dry, warm, and functional.

- Durability Under Systemic Stress: The boot is engineered to withstand the unique torsional forces applied by skis and snowshoes, preventing the material fatigue that leads to sloppy fits and eventual component failure.

This is not just a boot; it is a foundational solution. It’s the product of understanding that in winter operations, you are only as strong as the link between your foot and the snow.

From Preventing Failure to Enabling Success: The New Operational Horizon

When you solve the system integration problem at its source, you do more than just prevent broken binding straps. You unlock a new level of operational capability.

With a truly reliable mobility platform, teams are no longer just surviving in the cold; they are thriving. They can:

- Extend Operational Range: Move faster, more efficiently, and with less fatigue, covering more ground with greater safety.

- Increase Mission Complexity: Confidently take on more challenging terrain and conditions, knowing their core equipment is a stable and predictable asset, not a liability.

- Reduce Cognitive Load: Operators can focus on the mission, not on constantly checking and adjusting their gear.

- Improve Long-Term ROI: For procurement managers and brand owners, this means fewer failures, higher user trust, a stronger reputation, and a drastically lower total cost of ownership.

The goal shifts from simply avoiding equipment failure to actively enabling mission success.

Your challenge isn't just sourcing footwear; it's building a reliable operational system that your teams can depend on when everything is on the line. As large-scale manufacturers, our expertise goes beyond production. We partner with distributors, brands, and organizations to engineer footwear that serves as the bedrock of a successful mission system. To discuss how a systems-based approach to footwear can elevate your operational capabilities, we invite you to connect with our team. Contact Our Experts

Visual Guide

Related Products

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

- Wholesale Lightweight Tactical Boots Custom Manufacturer for Desert & Combat Use

- High-Traction Suede Tactical Boots Wholesale & Custom Manufacturing

- Wholesale Durable Mid-Cut Tactical Boots for Custom & Private Label Brands

Related Articles

- How Tactical Boots Solve Real-World Challenges: From Work Sites to Wilderness

- How to Verify Tactical Boot Reliability for Life-Saving Performance

- How to Choose Tactical Boots That Match Your Law Enforcement Needs

- How Tactical Boots Are Engineered to Last: The Science Behind Long-Lasting Performance

- How Tactical Boots Solve Critical Challenges in Law Enforcement Operations