You’ve done your due diligence. You invested in a bulk order of high-performance tactical boots for your team, choosing a reputable brand with stellar reviews. The shipment arrives, the gear is distributed, and for a few weeks, all seems well. Then, the reports start trickling in: blisters, arch pain, complaints about instability on uneven ground. Soon, you’re dealing with a surge in returns, requests for different sizes, and even a report of a sprained ankle. Your investment in top-tier equipment is now causing downtime and eroding morale. What went wrong?

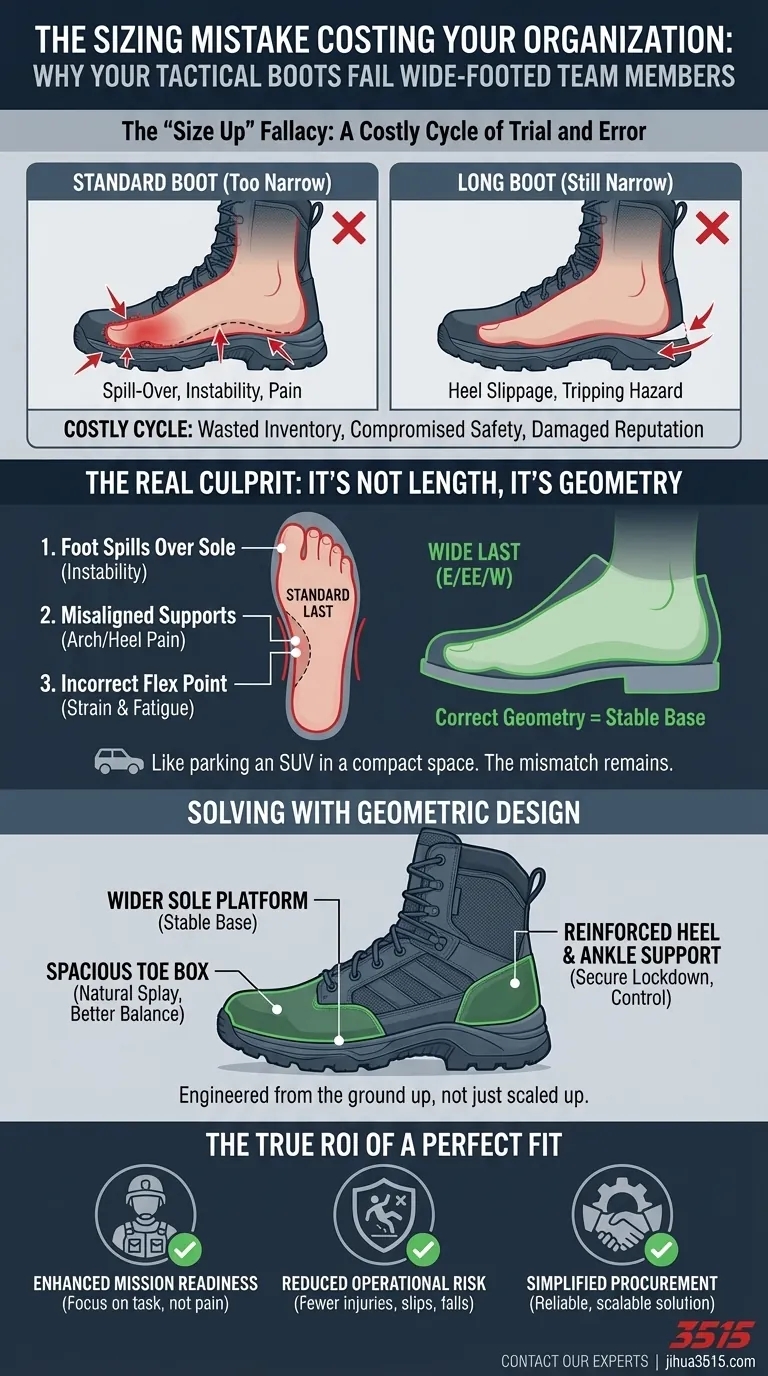

The "Size Up" Fallacy: A Costly Cycle of Trial and Error

This scenario is frustratingly common for distributors, brand owners, and procurement managers. When faced with fit complaints, the default solution is often to tell the user to “just go up half a size.” This seems logical, but it rarely works. In fact, it often makes the problem worse.

This creates a costly cycle:

- Wasted Inventory: Boots that are too long but still too narrow create a new set of problems, like heel slippage and tripping hazards. They end up back in the warehouse, unsellable.

- Compromised Safety & Performance: Team members in ill-fitting boots are less stable, fatigue faster, and are demonstrably more prone to injury. This isn't just a comfort issue; it's an operational risk.

- Damaged Reputation: Whether it’s your employees or your customers, providing gear that consistently fails a significant portion of users damages trust. It suggests a lack of understanding of their real-world needs.

Attempting to solve the problem by switching brands often just repeats the cycle, because the issue isn't the brand—it's the fundamental design philosophy behind standard-fit boots.

The Real Culprit: It's Not About Length, It's About Geometry

Here is the truth that turns the problem on its head: For a wide foot, the problem is not one of length, but of geometry.

Think of it like this: Trying to fit a wide foot into a standard-width boot by ordering a longer size is like trying to park an SUV in a space designed for a compact car. You can pull further in, but the sides will always spill over the lines. The fundamental mismatch remains.

A standard tactical boot is built on a foot-shaped model (called a "last") with specific proportions. Its entire support system—the width of the sole, the location of the arch support, the curve of the heel cup—is engineered for that standard shape. When a wider foot is forced into it, this is what happens:

- The Foot Spills Over the Sole: The edge of the foot is no longer on the stable platform of the outsole. This is the direct cause of the instability and rolled ankles your team reports.

- Structural Supports are Misaligned: The built-in arch support now pokes into the wrong part of the foot, causing pain. The heel isn't properly seated, leading to blisters from rubbing.

- The Flex Point is Incorrect: The boot is designed to bend at the ball of a standard foot. A wider foot, squeezed in, forces the boot to bend at an unnatural point, leading to strain and rapid fatigue.

The "size up" approach and other common "fixes" fail because they never address this core geometric conflict. They are temporary patches on a foundational design flaw.

Solving a Geometry Problem with Geometric Design

To truly solve this issue, you don't need a longer boot. You need a boot built on an entirely different foundation—one engineered from the ground up for the dimensions of a wide foot.

This is where a manufacturing-first approach becomes critical. A true wide-fit solution isn't just about using more leather. It's about utilizing a completely different set of lasts (E, EE, or W widths) that serve as the blueprint for the entire boot.

As a large-scale footwear manufacturer, 3515 builds boots to solve these exact structural challenges. A correctly engineered wide boot doesn't just feel better; it functions better by directly countering the root causes of failure:

- The Problem: Foot spilling over the sole.

- The Solution: A wider sole platform and a last that provides the necessary width across the ball of the foot, creating a stable base of support.

- The Problem: Crushed toes and pressure points.

- The Solution: A genuinely spacious toe box that allows toes to splay naturally for better balance, combined with a lace-to-toe system that allows for a secure fit without creating constriction.

- The Problem: Heel slippage and poor lockdown in oversized boots.

- The Solution: A reinforced heel counter and robust ankle support built to the proportions of a wide foot, ensuring the foot is locked in place for maximum control and safety.

This isn't just a boot that comes in a "wide" option; it's a piece of equipment where every component has been designed and manufactured in concert to support a wider foot's geometry.

Beyond Comfort: The True ROI of a Perfect Fit

When you solve the fit problem at its source, you unlock significant business value that goes far beyond simply reducing complaints.

For distributors and brand owners, it means offering a product that serves a broader market with confidence, dramatically reducing return rates and building a reputation for quality and expertise. For organizations outfitting their teams, the benefits are even more direct:

- Enhanced Mission Readiness: Your team can focus fully on the task at hand, not the pain in their feet.

- Reduced Operational Risk: Properly supported personnel are less likely to suffer from the slips, falls, and strains that lead to costly downtime and potential liability.

- Simplified Procurement: You can eliminate the guesswork and costly trial-and-error from your purchasing process, knowing you are providing a solution that works for everyone.

A boot is more than footwear; it's a critical piece of equipment that directly impacts safety, endurance, and effectiveness. Your challenge isn't just finding a wide boot; it's implementing a reliable, scalable solution that enhances performance across your entire operation. Our expertise lies in manufacturing footwear that meets these precise, demanding specifications for our B2B clients. Let's discuss how we can help you solve your team's specific fit and performance challenges.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

Related Articles

- How Steel Toe Boots Meet Industry Safety Standards and Reduce Workplace Injuries

- How to Choose Safety Footwear That Solves Steel Toe Shoe Problems Without Sacrificing Protection

- How to Choose Steel Toe Shoes That Balance Safety and Comfort

- How to Reduce Steel Toe Boot Risks Without Compromising Workplace Safety

- Matching Men’s Work Shoe Safety Technologies to Workplace Hazards