When investing in quality footwear, construction method determines longevity, comfort, and functionality. Two dominant techniques—stitchdown and Goodyear welt—offer distinct advantages depending on your lifestyle, budget, and environment. This guide compares their structural differences, real-world performance, and ideal use cases to help you make an informed decision.

Structural Differences and Performance Trade-offs

Goodyear Welt: The Resoling Champion

Goodyear welt construction uses a leather strip (welt) stitched between the upper and sole. This creates:

- Double-stitch durability: The welt acts as a buffer, allowing repeated resoling without damaging the upper.

- Machine precision: Consistent tension in stitching enhances structural integrity.

- Moderate water resistance: The welt gap can trap moisture, though storm welts mitigate this.

Stitchdown: The Workhorse Alternative

Stitchdown skips the welt, sewing the upper directly to the midsole. Key traits:

- Superior water resistance: Fewer entry points for moisture compared to Goodyear welts.

- Flexible fit: The absence of a welt allows the upper to mold closely to the foot.

- Simpler repairs: Resoling requires less specialized labor but may limit sole replacement options.

Trade-off: Goodyear welts excel in long-term repairability, while stitchdown prioritizes immediate durability and weatherproofing.

Durability and Longevity in Real-World Scenarios

Goodyear Welt for Urban and Formal Use

- Office shoes: The refined structure supports all-day wear without fatigue.

- Heritage styles: Resole up to 5–7 times, ideal for leather boots meant to last decades.

Stitchdown for Rugged Conditions

- Work boots: Withstands abrasion and moisture in construction or outdoor jobs.

- Hiking: The direct upper-to-sole stitch reduces failure points under heavy loads.

Pro Tip: For mixed use (e.g., commuting and light trails), Goodyear welts with rubber soles offer a balanced solution.

Water Resistance and Environmental Adaptability

| Factor | Goodyear Welt | Stitchdown |

|---|---|---|

| Rain | Moderate (with storm welt) | High (fewer seams) |

| Snow | Good with insulation | Excellent (sealed edges) |

| Mud/Slush | Prone to debris trapping | Sheds debris easily |

Key Insight: Stitchdown’s flush stitching outperforms in wet climates, while Goodyear welts benefit from aftermarket treatments like waxed laces.

Cost, Repairability, and Aesthetic Considerations

Budget and Maintenance

- Goodyear welt: Higher upfront cost (~20–30% more than stitchdown) but lower lifetime cost due to easy resoling.

- Stitchdown: Lower initial price but may require full sole replacements instead of partial repairs.

Style Flexibility

- Goodyear welt: Clean lines suit dress shoes and classic boots.

- Stitchdown: Bulkier profile ideal for tactical or heritage workwear looks.

Case Studies: Ideal Use Cases for Each Method

Choose Goodyear Welt If You...

- Prioritize long-term value (e.g., Allen Edmonds dress shoes).

- Need versatile footwear for urban environments.

Opt for Stitchdown If You...

- Work in wet or abrasive conditions (e.g., Red Wing Iron Rangers).

- Prefer a "break-in and forget" boot with minimal maintenance.

Final Recommendation

Match construction to your dominant use case:

- Frequent resoling → Goodyear welt

- Daily abuse → Stitchdown

For distributors and brands seeking durable footwear solutions, 3515 offers both constructions tailored to bulk clients’ needs—from boardroom-ready Goodyear welts to industrial-grade stitchdown work boots.

Ready to stock high-performance footwear? Partner with 3515 for scalable production across all shoe types.

Related Products

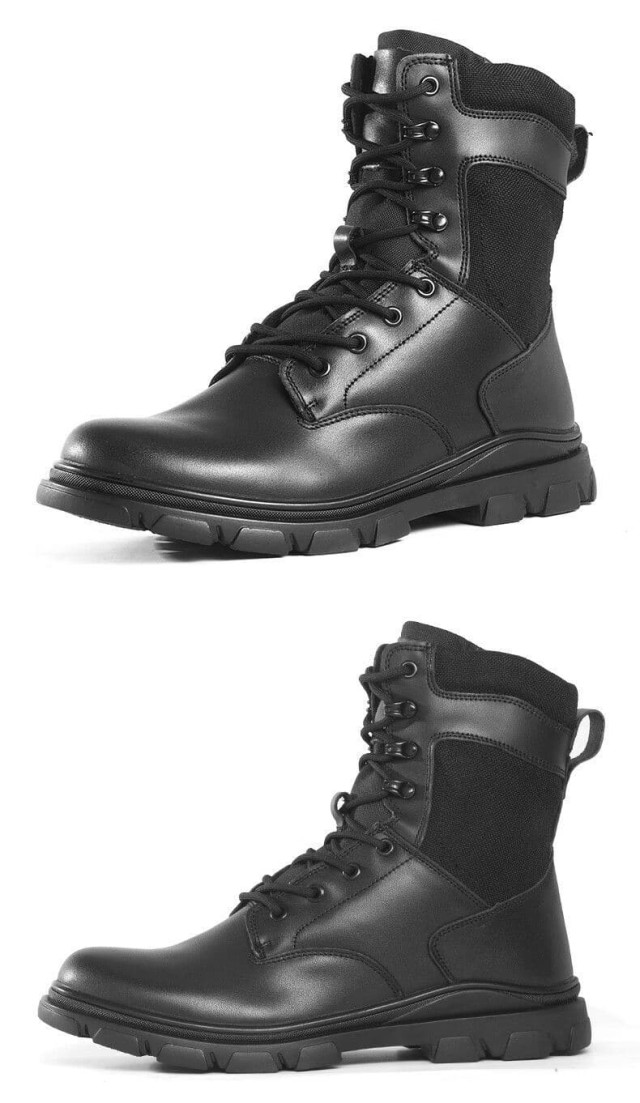

- Wholesale Durable Leather Work Boots | 8-Inch Goodyear Welt Manufacturer

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Wholesale Leather Work Boots with Customizable Wedge Sole for Brands

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

Related Articles

- How to Choose Work Boot Materials: Balancing Weight, Safety, and Job-Specific Needs

- How Work Boot Materials and Technologies Shield Against Cold Weather Hazards

- How Work Boot Safety Features Counteract Industry-Specific Workplace Hazards

- How Work Boot Components Address Safety and Comfort in High-Risk Jobs

- How Advanced Tactical Boot Technologies Enhance Law Enforcement Performance