When selecting safety footwear, the debate often centers on one critical question: Should you prioritize lightweight mobility or long-term durability? The answer depends on your work environment, daily tasks, and comfort needs. This guide breaks down the steel vs. non-steel toe dilemma, helping you match the right protection to your job’s unique demands.

Material Science Breakdown: What Makes Non-Steel Toes Lighter?

Non-steel safety toes (made from composites, aluminum, or alloys) are 30–50% lighter than traditional steel caps. Here’s why:

- Composite materials (e.g., fiberglass, Kevlar) use layered polymers that distribute impact forces without the density of metal. They’re also non-conductive, making them ideal for electrical work or extreme temperatures.

- Aluminum/alloy toes provide comparable protection to steel but with reduced weight and slimmer profiles, offering more toe-box space.

Trade-off note: While lighter, non-steel materials may show wear faster in high-abrasion environments like construction or mining.

Mobility vs. Impact Resistance: Which Matters More for Your Job?

Prioritize Lightweight Mobility If:

- Your role involves prolonged walking/climbing (e.g., warehouse logistics, roofing).

- You work in temperature extremes (composites won’t conduct heat/cold like steel).

- You need electrical hazard protection (non-metallic toes reduce shock risks).

Opt for Steel Toes If:

- Your job exposes shoes to heavy impacts or compression (e.g., manufacturing, heavy machinery operation).

- You prioritize decades-long durability over weight savings.

- Your workplace has sharp debris (steel resists punctures better than some composites).

Reflective question: How many steps do you take daily? For workers logging 10,000+ steps, a 30% lighter toe could reduce fatigue significantly.

Longevity Under Pressure: How Work Environments Affect Durability

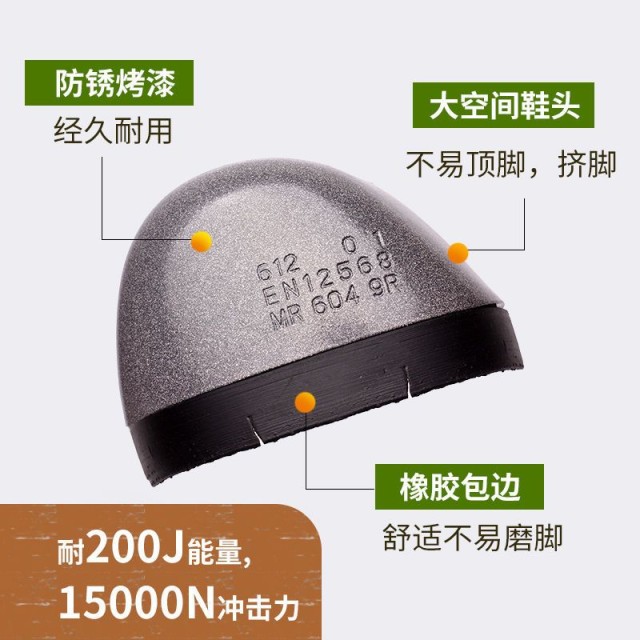

Steel toes excel in harsh conditions but come with drawbacks:

- Corrosion risk in wet environments (unless treated with anti-rust coatings).

- Weight fatigue during long shifts.

Non-steel alternatives shine in specialized scenarios:

- Chemical exposure: Composites won’t degrade like untreated metals.

- Airport security: Aluminum toes avoid metal detector triggers.

Data insight: Research shows alloy toes maintain protective strength over time but may dent under repeated extreme impacts, whereas steel bends but rarely cracks.

Industry-Specific Recommendations: Matching Toe Type to Task

- Construction/Manufacturing: Steel toes for crush protection against heavy materials.

- Electrical Utilities: Composite toes to prevent conductivity.

- Food Processing: Aluminum/alloy for lightweight, corrosion-resistant wear.

- Landscaping: Composite toes to avoid heat retention in outdoor heat.

Closing thought: The best safety toe isn’t about "strongest" or "lightest"—it’s about aligning with hazards you actually face daily.

Ready to Equip Your Team with the Right Safety Footwear?

3515 partners with distributors and brands to deliver tailored safety footwear solutions for every industry. Whether you need steel-toe durability for warehouse crews or featherlight composites for electricians, our manufacturing expertise ensures certified protection without compromising comfort.

Contact 3515 today to discuss bulk orders designed for your workforce’s unique challenges.

Products You Might Be Looking For:

View durable steel toe work boots

Related Products

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Athletic Safety Shoes with Dial Closure & Steel Toe for Wholesale & Custom Manufacturing

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

Related Articles

- Steel Toe Work Boots: Balancing Safety and Comfort for Demanding Jobs

- Matching Men’s Work Shoe Safety Technologies to Workplace Hazards

- How Steel Toe Boots Meet Industry Safety Standards and Reduce Workplace Injuries

- How Safety Standards for Steel Toe Boots Protect Workers Beyond Impact Resistance

- How Safety Work Boots Engineer Protection: Features and Standards for Targeted Hazard Mitigation