Law enforcement officers face unpredictable hazards daily—from high-impact foot injuries during arrests to electrical threats at accident scenes. Quality police boots aren’t just about comfort; they’re engineered to mitigate these specific risks. This article breaks down how key boot features directly address on-duty dangers, backed by safety standards and real-world applicability.

Toe Caps: Guarding Against Crush Injuries in High-Impact Scenarios

The Risk: During arrests, vehicle extrications, or crowd control, officers’ feet are vulnerable to heavy falling objects or compression. A single crush injury can lead to permanent disability.

The Solution: ASTM F2413-compliant toe caps (marked with an "I" rating) withstand up to 75 pounds of force—equivalent to a 20-pound tool dropped from 3 feet. These caps are typically made of steel, composite, or aluminum, offering protection without excessive weight.

Real-World Link: Consider a foot chase ending in a suspect’s garage. Steel-toe boots could prevent broken metatarsals when a car jack slips from a shelf.

Traction Matters: Preventing Slips During Pursuits and Wet Operations

The Risk: Over 20% of officer injuries stem from slips on wet pavement, oil spills, or unstable terrain. Poor traction delays response times and increases fall-related fractures.

The Solution: Advanced outsole designs use:

- Multi-directional lugs for grip on uneven surfaces

- Hydrophobic rubber compounds that repel water and oil

- Deep grooves to channel debris away from the contact zone

Pro Tip: Look for boots tested against ASTM F1677 (slip resistance on wet surfaces). A 45-degree incline test is a common benchmark.

Electrical Hazards: Silent Threats and How EH Ratings Save Lives

The Risk: Officers responding to downed power lines or car accidents may encounter live wires. Even minor electrical exposure can cause cardiac arrest.

The Solution: EH-rated boots (per ASTM F2413) use insulating materials like vulcanized rubber to block circuits up to 600V in dry conditions. Some premium models resist 18,000V with leakage below 1mA—critical when stepping near a live wire during a storm.

Case Example: A sheriff’s deputy kneeling on wet pavement to assist at a crash site avoids electrocution because their boots disrupt the current path.

Waterproofing: Sustaining Mobility in Extreme Weather Deployments

The Risk: Wet feet reduce mobility, cause trench foot, and increase fatigue during prolonged operations like flood rescues.

The Solution: Modern waterproof membranes (e.g., Gore-Tex®) allow sweat vapor to escape while blocking external moisture. Seam-sealed construction prevents leaks at stitching points.

Durability Note: Officers in coastal regions should prioritize boots with anti-corrosion hardware (e.g., rust-proof eyelets) to combat saltwater degradation.

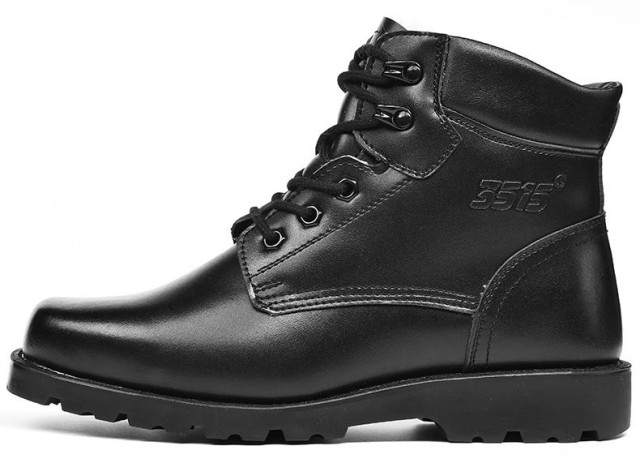

Why Trust 3515 for Your Department’s Footwear Needs?

With decades of expertise in safety footwear manufacturing, 3515 delivers boots that meet and exceed ASTM standards. Our bulk production capabilities ensure consistent quality for distributors and agencies outfitting hundreds of officers.

Ready to equip your team with boots that turn hazards into afterthoughts? Contact 3515 today to discuss custom solutions tailored to your operational risks.

Related Products

- Durable Mid-Cut Tactical Boots for Wholesale & Private Label

- Wholesale Durable Mid-Cut Tactical Boots for Custom & Private Label Brands

- Durable Leather Moc Toe Work Boots for Wholesale & Custom Manufacturing

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

- Durable Moc-Toe Wedge Work Boots | Wholesale Manufacturing for Brands

Related Articles

- How Tactical Boots Solve Critical Challenges in Law Enforcement Operations

- How Tactical Boots Solve Everyday Challenges: From City Streets to Job Sites

- How Tactical Boots Solve Real Workplace Challenges in High-Risk Environments

- How Tactical Boots Evolved: Engineering Breakthroughs That Redefined Work Footwear

- How to Choose Tactical Boots That Match Your Law Enforcement Needs