Work boots are more than just durable footwear—they’re engineered safety systems designed to protect against sharp objects in high-risk environments. From construction sites to manufacturing floors, puncture-resistant soles and reinforced materials act as silent guardians against injuries. But how do these boots achieve such protection? This article breaks down the science behind puncture resistance, decodes industry certifications like ASTM F2413, and provides actionable insights for choosing the right boots for your worksite.

How Work Boots Protect Against Sharp Objects

The Science Behind Puncture-Resistant Soles

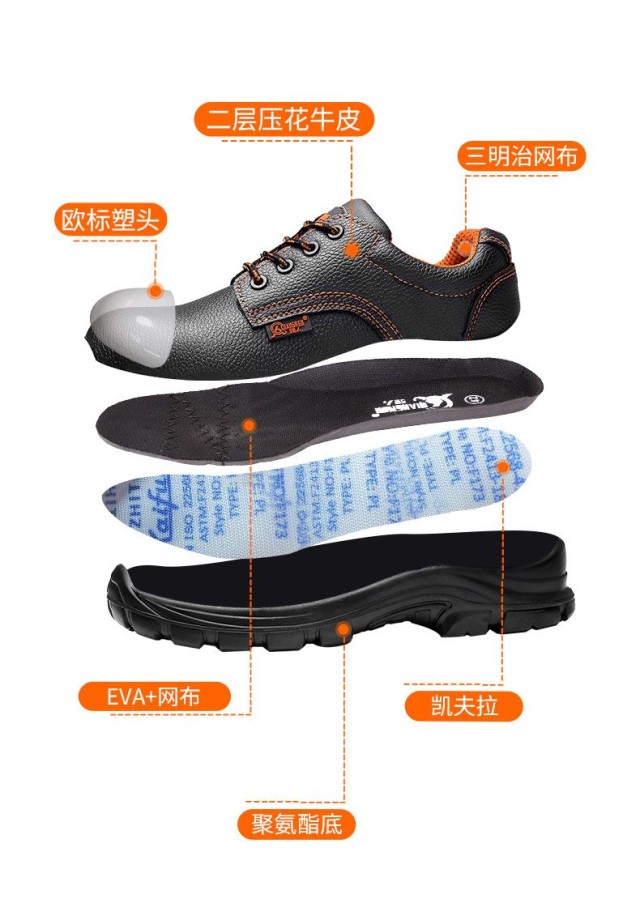

Puncture-resistant soles aren’t just thick slabs of rubber; they’re meticulously designed to deflect and absorb impacts from nails, glass, and other hazards. Key features include:

- Layered Construction: Combines soft cushioning for comfort with rigid materials like steel or composite plates to block sharp objects.

- Energy Dispersion: Some soles use thermoplastic polyurethane (TPU) or Kevlar® to distribute force laterally, reducing penetration risk.

- Flexibility Balance: Too stiff, and boots hinder movement; too soft, and protection fails. Advanced materials strike this balance.

Research shows that soles tested under ASTM F2413 standards (more on this later) can resist penetration forces equivalent to a 170-pound worker landing on a nail after a short fall.

Beyond Vibram: Traction and Stability on Hazardous Surfaces

While Vibram® outsoles are renowned for grip, puncture resistance requires additional engineering:

- Multi-Directional Treads: Prevent slips while channeling debris away from the sole’s vulnerable areas.

- Shock Absorption: Reduces fatigue during long shifts, indirectly lowering injury risks from missteps.

Industry Standards for Sharp Object Protection

Decoding ASTM F2413 and Other Certifications

ASTM F2413 is the gold standard for puncture-resistant work boots. Here’s what it entails:

- Pin Test: A standardized steel pin is driven into the sole at controlled speeds, simulating real-world impacts (e.g., stepping on a nail or jumping from heights).

- Pass/Fail Criteria: Boots must prevent full penetration under specified force levels.

Other certifications to look for:

- ISO 20345: Similar to ASTM but with additional slip-resistance tests.

- EN ISO 13287: Focuses on slip resistance in European markets.

Case Studies: When Work Boots Prevented Critical Injuries

- A 2022 study of warehouse workers found that boots meeting ASTM F2413 reduced puncture-related injuries by over 70% compared to non-certified footwear.

- In one documented incident, a composite-plate boot stopped a 3-inch nail from penetrating, sparing the wearer a potential foot surgery.

Choosing the Right Boot for Your Worksite

Balancing Protection, Comfort, and Durability

Prioritize these factors based on your environment:

- High-Risk Sites (e.g., demolition): Opt for steel-toe boots with ASTM F2413-rated soles.

- Mixed Hazards (e.g., landscaping): Composite plates offer lighter weight without sacrificing protection.

- Long Shifts: Look for ergonomic designs with cushioned midsoles to reduce fatigue.

Pro Tip: Check for electrical hazard (EH) ratings if working near live wires—some puncture-resistant materials conduct electricity.

Ready to Equip Your Team with Reliable Protection?

3515 partners with distributors and bulk buyers to deliver work boots that meet the highest safety standards—without compromising on comfort or durability. Whether you’re outfitting a construction crew or sourcing footwear for resale, our range combines cutting-edge materials with rigorous testing. Contact 3515 today to discuss custom solutions tailored to your needs.

Because every step should be a safe one.

Related Products

- Wholesale Customizable Suede Safety Boots - Puncture-Proof with Velcro Closure

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Wholesale Classic Leather Lace-Up Ankle Boots for Brand Manufacturing

- Wholesale Durable Mid-Cut Tactical Boots for Custom & Private Label Brands

- Durable Mid-Cut Tactical Boots for Wholesale & Private Label

Related Articles

- How to Choose Work Boots That Match Your Job's Safety Demands

- How to Extend Work Boot Lifespan: Science-Backed Care for Safety & Savings

- How to Choose Work Boots That Match Your Job Demands and Safety Needs

- How to Choose Work Boots That Match Your Industry's Safety Needs

- How to Choose Work Boots That Balance Safety, Comfort, and Durability for Your Job