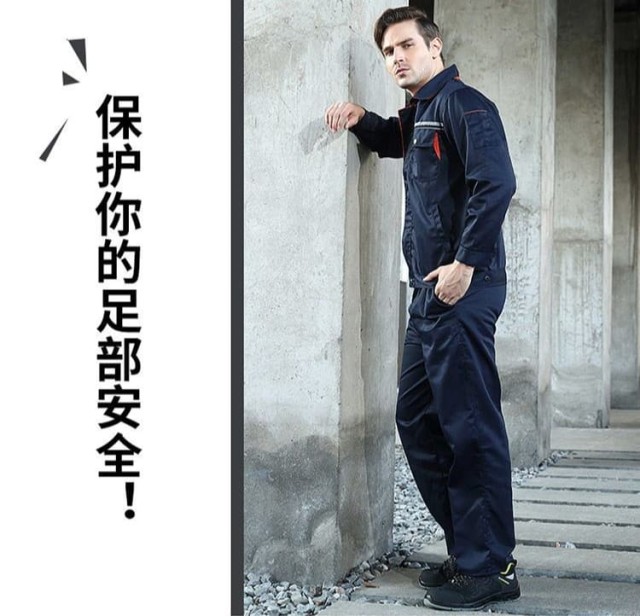

Every step in hazardous environments relies on footwear engineered for protection. This guide deciphers work boot components and job-specific safety features—helping you select boots that reduce injury risks while enduring daily wear.

Anatomy of a Work Boot

The Outsole: Your First Line of Defense Against Workplace Hazards

The outsole determines traction, stability, and puncture resistance. Research shows:

- Rubber compounds (e.g., Vibram) excel in grip and chemical resistance, critical for construction sites. Deep lug patterns prevent slips on uneven terrain, while shallow lugs minimize mud buildup for landscapers.

- Slip-resistant designs meet OSHA requirements for wet/oily surfaces, reducing fall-related injuries—a leading cause of workplace accidents.

Tip: Prioritize outsoles with oil- and abrasion-resistant ratings if you work with machinery or solvents.

The Midsole: Engineering Comfort for High-Impact Environments

Midsoles absorb shock from prolonged standing or heavy loads:

- Polyurethane (PU) balances cushioning and durability, ideal for warehouse roles.

- EVA foam is lighter, suited for trades requiring mobility (e.g., roofing), though it compresses faster under heavy equipment.

Did you know? A well-cushioned midsole can reduce fatigue-related errors by up to 30% in 10-hour shifts.

The Insole: Custom Support for All-Day Wear

Replaceable insoles address individual needs:

- Arch support prevents plantar fasciitis for workers on hard surfaces.

- Moisture-wicking linings combat fungal infections in hot/humid conditions.

The Upper: Balancing Durability and Workplace Safety Risks

Materials dictate protection levels:

- Full-grain leather resists abrasions and sparks, vital for welding.

- Waterproof membranes (e.g., Gore-Tex) shield against rain and chemicals, while breathable mesh suits moderate climates.

Pro insight: Reinforced toe caps (steel or composite) meeting ASTM F2413-18 prevent crush injuries from falling objects—a non-negotiable for construction.

Choosing the Right Boot for Your Job

Construction Sites: Slip Resistance and Puncture Protection

- Key features: Vibram outsoles, ASTM F2413-11 puncture-resistant plates, and metatarsal guards.

- Why it matters: Construction workers face 25% higher foot injury risks than other industries, often from sharp debris or unstable surfaces.

Electrical Work: Non-Conductive Materials and ASTM Standards

- Key features: EH-rated boots (tested at 18,000 volts), non-metallic components.

- Safety note: ASTM F2413 certifies electrical hazard protection, but always de-energize circuits—boots are a last-resort safeguard.

Landscaping: Waterproofing and Chemical Resistance

- Key features: Rubberized uppers repel moisture and herbicides, while lugged outsoles navigate mud.

- Durability hack: Boots with sealed seams prevent water ingress during irrigation or storm cleanup.

Upgrade Your Safety with 3515’s Work Boot Solutions

Whether you’re a distributor supplying construction crews or a brand owner catering to electricians, 3515’s manufacturing expertise delivers boots that merge OSHA compliance with all-day comfort. Partner with us to equip workers with footwear that outlasts job demands—request a catalog today.

Related Products

- Wholesale Customizable Suede Safety Boots - Puncture-Proof with Velcro Closure

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Athletic Safety Shoes with Dial Closure & Steel Toe for Wholesale & Custom Manufacturing

Related Articles

- Steel Toe Work Boots: Balancing Safety and Comfort for Demanding Jobs

- Work Boots vs. Western Boots: How to Choose the Right Footwear for Labor Safety

- How to Choose Work Boot Materials for Maximum Safety and Durability

- How to Choose Work Boots That Balance Safety, Comfort, and Durability for Your Job

- How Safety Work Boots Engineer Protection: Features and Standards for Targeted Hazard Mitigation