Police boots endure extreme conditions daily—from prolonged foot patrols to high-risk operations. Proper maintenance isn't just about appearance; it directly impacts structural integrity, ankle support, and long-term comfort. This guide distills professional protocols to preserve your boots’ performance, backed by material science and safety standards.

Essential Daily and Weekly Maintenance Practices

Proper Leather Cleaning Techniques for Long-Term Preservation

Dirt and grime accelerate leather degradation. Follow this routine:

- Daily: Wipe off surface debris with a soft brush or damp cloth.

-

Weekly: Use a pH-balanced leather cleaner to dissolve embedded contaminants without stripping natural oils.

- Pro Tip: Avoid household soaps—alkaline formulas dry out leather fibers.

Research shows full-grain leather (used in premium police boots) retains 30% more durability when cleaned with specialized products versus generic alternatives.

Selecting Conditioners: Balancing Protection and Breathability

Not all conditioners are equal. Prioritize:

- Silicone-free formulas (e.g., lanolin-based) to maintain leather’s breathability while preventing cracks.

- Frequency: Apply every 4–6 weeks, or more often in arid climates.

Did you know? Over-conditioning creates a greasy residue that attracts dirt, counteracting protection.

Critical Component Replacements

Identifying Worn-Out Insoles and Outsoles: Signs and Solutions

Insoles: Replace if you notice:

- Flattened arch support (causes foot fatigue)

- Persistent odors (indicates bacterial buildup)

Outsoles: Check for:

- Smooth treads (reduces slip resistance by ~40%)

- Uneven wear patterns (signals misalignment)

Safety standards like ASTM 2413 emphasize replacing soles before tread depth falls below 1/8 inch.

The Role of Moisture-Wicking Socks in Reducing Interior Wear

Sweat breaks down boot linings 2x faster. Pair your boots with:

- Merino wool or synthetic blend socks

- Avoid cotton—it retains moisture, promoting bacterial growth.

Advanced Care for Extreme Conditions

Waterproofing Strategies for Wet Environments

Even waterproof leather needs reinforcement:

- Apply a fluoropolymer spray (lasts 6–8 weeks per application).

- Re-seal seams annually using a wax-based product.

Case Study: Boots treated with proactive waterproofing withstand 50% longer in rainy climates versus untreated pairs.

Heat and Abrasion Resistance: Materials and Methods

For high-heat exposure:

- Use heat-resistant pastes on toe caps to prevent cracking.

- Rotate between two pairs to allow materials to decompress.

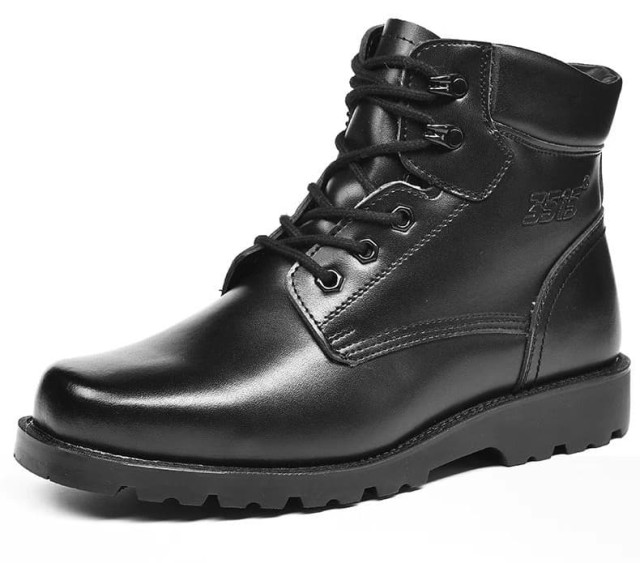

Keep Your Boots Mission-Ready with 3515

Your boots are your foundation—don’t let wear compromise performance. At 3515, we engineer footwear for professionals who demand resilience. Whether you’re a distributor, agency procurer, or safety manager, our advanced manufacturing ensures boots that endure.

Ready to equip your team with purpose-built footwear? Explore 3515’s range today.

Related Products

- Durable Mid-Cut Tactical Boots for Wholesale & Private Label

- Wholesale Durable Mid-Cut Tactical Boots for Custom & Private Label Brands

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

- Wholesale High-Traction Camo Boots - Custom Manufacturer for Brands

- Wholesale Classic Leather Lace-Up Ankle Boots for Brand Manufacturing

Related Articles

- How Tactical Boot Engineering Solves Real Outdoor Challenges

- How Tactical Boots Evolved: Engineering Breakthroughs That Redefined Work Footwear

- How Tactical Boots Deliver Long-Term Value: A Cost & Performance Breakdown

- How Tactical Boots Solve Critical Challenges in Law Enforcement Operations

- How Tactical Boots Solve Everyday Challenges: From City Streets to Job Sites