Military personnel, outdoor workers, and tactical enthusiasts need combat boots that withstand punishing environments. While basic cleaning helps, specialized maintenance protocols can double or triple your footwear's service life. Here's how to optimize performance across materials and conditions.

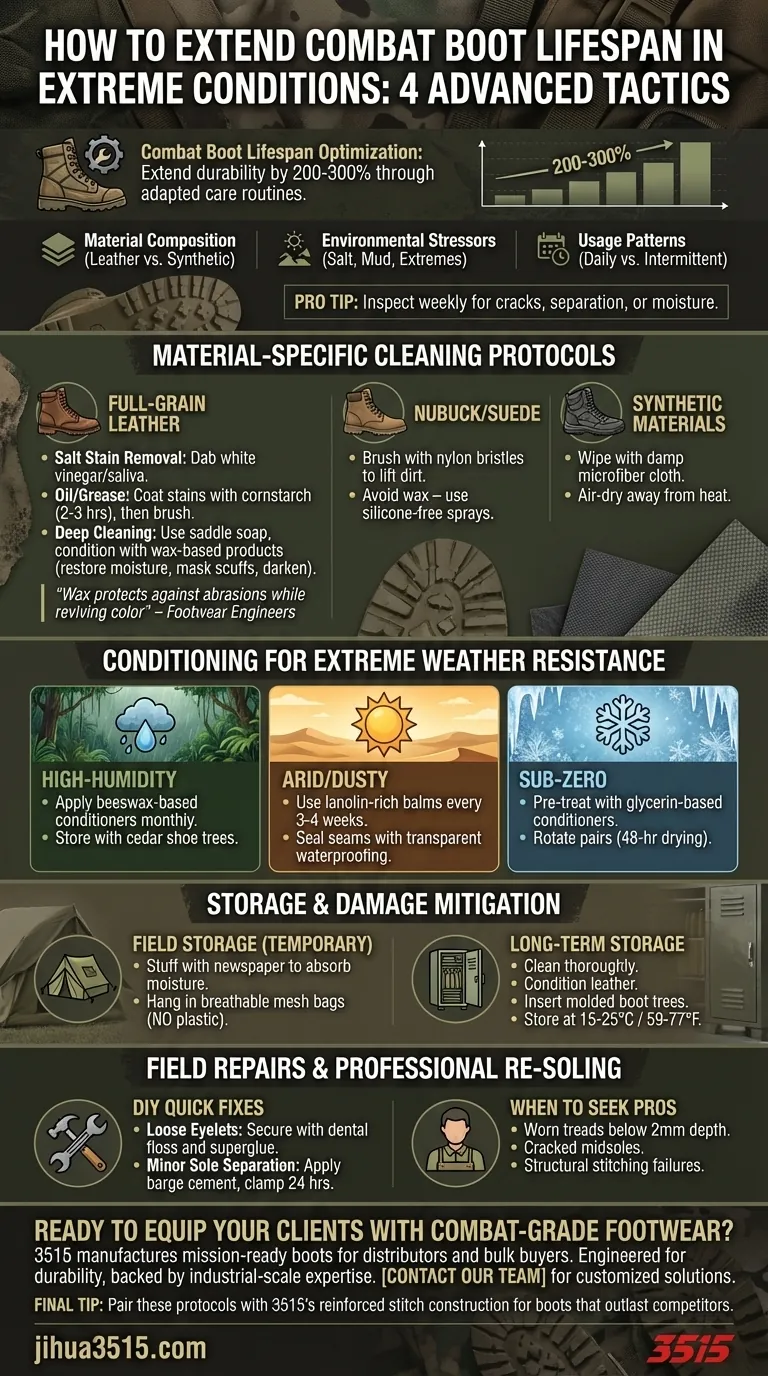

Combat Boot Lifespan Optimization

Research shows proper care can extend boot durability by 200-300% in harsh environments. The key lies in adapting your routine to:

- Material composition (leather vs. synthetic)

- Environmental stressors (salt, mud, extreme temps)

- Usage patterns (daily wear vs. intermittent use)

Pro Tip: Inspect boots weekly for early signs of cracking, sole separation, or moisture damage.

Material-Specific Cleaning Protocols

Full-Grain Leather Boots

- Salt Stain Removal: Dab white vinegar (or saliva) on stains—water spreads salt crystals.

- Oil/Grease Treatment: Coat stains with cornstarch for 2-3 hours before brushing.

- Deep Cleaning: Use saddle soap, then condition with wax-based products to:

- Restore moisture

- Mask scuffs

- Darken leather uniformly (test first)

"Full-grain leather wax protects against abrasions while reviving color," notes footwear engineers.

Nubuck/Suede Boots

- Brush with nylon bristles to lift dirt

- Avoid wax—use silicone-free sprays to maintain texture

Synthetic Materials

- Wipe with damp microfiber cloth

- Air-dry away from heat sources

Conditioning for Extreme Weather Resistance

High-Humidity Environments

- Apply beeswax-based conditioners monthly

- Store with moisture-wicking cedar shoe trees

Arid/Dusty Conditions

- Use lanolin-rich balms every 3-4 weeks

- Seal seams with transparent waterproofing compounds

Sub-Zero Temperatures

- Pre-treat with glycerin-based conditioners to prevent cracking

- Rotate pairs to allow 48-hour drying between uses

Storage and Damage Mitigation

Field Storage (Temporary)

- Stuff with newspaper to absorb moisture

- Hang in breathable mesh bags—never plastic

Long-Term Storage

- Clean thoroughly

- Condition leather

- Insert molded boot trees

- Store in climate-controlled spaces (15-25°C / 59-77°F)

Field Repairs and Professional Re-Soling

DIY Quick Fixes

- Loose Eyelets: Secure with dental floss and superglue

- Minor Sole Separation: Apply barge cement, clamp for 24 hours

When to Seek Pros

- Worn treads below 2mm depth

- Cracked midsoles

- Structural stitching failures

Ready to equip your clients with combat-grade footwear? 3515 manufactures mission-ready boots for distributors and bulk buyers—engineered for durability and backed by industrial-scale production expertise. [Contact our team] to discuss customized solutions.

Final Tip: Pair these protocols with 3515's reinforced stitch construction for boots that outlast competitors.

Visual Guide

Related Products

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Wholesale Tactical Boots High-Traction & Reflective for Bulk & Brand Orders

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

Related Articles

- How Tactical Boots Solve Real-World Challenges: From Work Sites to Wilderness

- How Tactical Boots Achieve All-Day Comfort: Science-Backed Design Secrets

- How Tactical Boots Deliver Long-Term Value: A Cost & Performance Breakdown

- How Tactical Boots Are Engineered to Last: The Science Behind Long-Lasting Performance

- How Tactical Boots Solve Real Workplace Challenges in High-Risk Environments