Selecting the right safety toe boots isn't just about compliance—it's about preventing injuries while maintaining comfort. Whether you're a distributor sourcing for clients or a brand owner curating protective gear, understanding how material properties and industry-specific risks intersect ensures optimal protection.

Safety Toe Boot Essentials for Hazardous Work Environments

Conclusion First: The best safety boots balance protection, comfort, and hazard-specific features.

Key Considerations:

- Hazard Type: Identify primary risks (impact, electrical, slip, or temperature extremes).

- Material Trade-offs: Steel toes offer maximum durability but conduct electricity; composites are lighter and non-conductive.

- Activity Level: Highly mobile workers need lightweight designs; static roles prioritize insulation.

Example: A construction worker facing falling debris needs ASTM F2413-compliant steel toes, while an electrician requires EH-rated composite toes.

How Material Choices Impact Protection

Steel vs. Composite vs. Alloy:

-

Steel Toe

- Pros: Highest impact resistance, cost-effective.

- Cons: Heavy, conducts electricity/cold.

- Best for: Manufacturing, heavy construction.

-

Composite Toe

- Pros: 30% lighter than steel, non-conductive, weather-insulating.

- Cons: Bulkier than alloy.

- Best for: Electrical work, cold environments, security-sensitive sites.

-

Alloy Toe

- Pros: Lightweight like composite but slimmer.

- Cons: Less insulation.

- Best for: Precision tasks needing agility.

Research shows composite toes reduce leg fatigue by 15–20% over steel in 10-hour shifts.

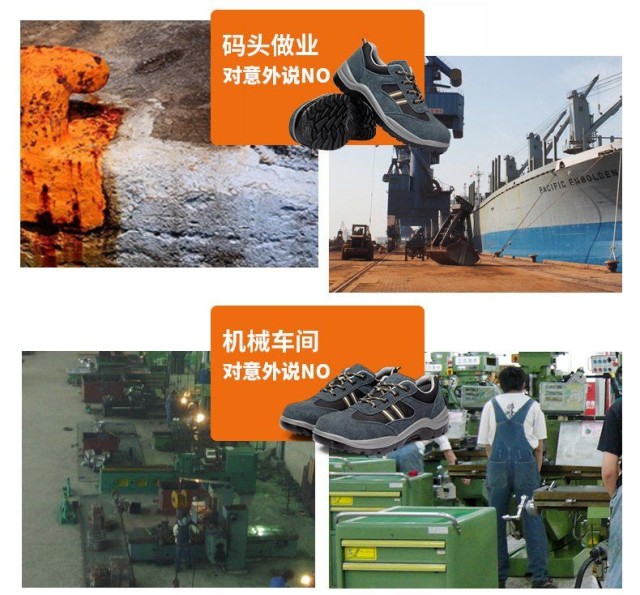

Matching Boot Features to Industry Risks

High-Risk Industries and Their Boot Requirements:

- Construction: Steel/metatarsal guards (ASTM F2413), slip-resistant soles.

- Electrical Work: EH-rated composite toes (non-conductive).

- Oil/Gas: Chemical-resistant uppers, spark-free soles.

- Cold Storage: Insulated (400g–1200g), waterproof linings.

Real-World Insight: Workers in welding environments often overlook heat-resistant soles—a critical feature for preventing burns from molten metal.

Compliance and Certification Standards

ASTM F2412 vs. F2413:

- F2412: Tests impact/compression resistance only.

- F2413: Adds metatarsal, electrical hazard (EH), and puncture protection.

Always verify: Labels like "EH" or "SR" (slip-resistant) must align with job hazards.

Real-World Scenarios and Injury Prevention

Case Study: A warehouse worker slipped on grease, fracturing an ankle. The root cause? Boots lacked oil-resistant soles despite working near machinery.

Prevention Checklist:

- Audit workplace hazards annually.

- Train workers on boot maintenance (e.g., replacing worn treads).

- Partner with manufacturers like 3515 for bulk orders tailored to industry needs.

Ready to Equip Your Workforce?

3515 delivers safety footwear solutions for distributors and brands—engineered for hazard-specific protection without compromising comfort. Contact us to customize bulk orders that align with your clients' unique risks.

Key Takeaways:

- Match toe material to electrical/impact risks.

- Prioritize ASTM F2413 for comprehensive protection.

- Insulation and slip resistance are as critical as toe caps.

Products You Might Be Looking For:

Explore customizable safety footwear for workplace hazards

Related Products

- Wholesale Customizable Suede Safety Boots - Puncture-Proof with Velcro Closure

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Durable Leather Safety Boots for Wholesale & Custom OEM Manufacturing

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

- Wholesale Durable Safety Boots | Custom Steel Toe & Puncture-Resistant Manufacturing

Related Articles

- How Safety Work Boots Engineer Protection: Features and Standards for Targeted Hazard Mitigation

- Matching Men’s Work Shoe Safety Technologies to Workplace Hazards

- Work Boots vs. Western Boots: How to Choose the Right Footwear for Labor Safety

- Steel Toe Work Boots: Balancing Safety and Comfort for Demanding Jobs

- How to Choose Work Boots That Match Your Industry's Safety Needs