Selecting the right safety boots isn’t just about compliance—it’s about creating a barrier between workers and preventable injuries. With workplace hazards ranging from falling objects to electrical currents, the ideal boot must align with three core factors:

- Hazard-Specific Protection (e.g., impact-resistant toes for construction, electrical insulation for utilities)

- Regulatory Compliance (ASTM/OSHA standards tailored to industries like mining or oil/gas)

- Long-Term Wearability (anti-fatigue designs for 12-hour shifts, slip-resistant soles for wet floors)

Below, we break down how to evaluate these priorities, backed by safety standards and material science.

Choosing Safety Boots for Hazard-Specific Work Environments

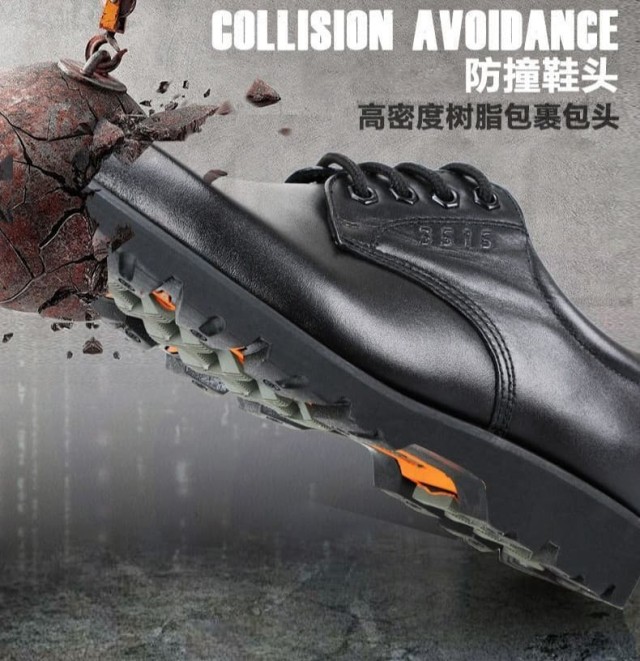

Matching Toe Protection to Physical Risks

Lead with the conclusion: Steel or composite toes are non-negotiable for heavy industries, but material choice depends on the force and frequency of impacts.

- Steel toes (ASTM F2413 I/75) withstand up to 75 pound-force impacts—critical for construction sites with falling tools.

- Composite toes offer similar protection with lighter weight, preferred for high-mobility roles like warehouse work.

- Avoid aluminum toes in extreme heat (e.g., foundries), as they conduct temperature more readily.

Reflective question: How often do your workers handle heavy equipment? A boot labeled "I/75" (impact-resistant) paired with "C/75" (compression-resistant) suits environments with rolling barrels or machinery.

Electrical Safety and Material Compliance

For utilities or oil/gas workers, static electricity or live wires demand boots with:

- EH-rated (Electrical Hazard) soles to reduce shock risks.

- Non-conductive materials like TPU outsoles, which resist oils and insulate up to 18,000 volts (per OSHA 29 CFR 1910.137).

Reference insight: Oil/gas boots often combine EH ratings with metatarsal guards—a shield over the laces to deflect pipe drops.

Weather Resistance and Workplace Climate Demands

- -40°F to 500°F ranges: Insulated liners (Thinsulate™) for cold storage, heat-resistant soles for welding.

- Wet environments: TPU outsoles outperform rubber in oil-rich settings, reducing slip risks by ~30% (per NIOSH traction studies).

Navigating Safety Standards and Certifications

Decoding ASTM/OSHA Labels for Boot Selection

Boot tags like ASTM F2413-18 indicate tested protections:

- "M" (Metatarsal guard)

- "Mt" (Puncture-resistant midsole)

- "SR" (Slip-resistant)

Pro tip: Construction boots in the U.S. must meet ASTM F2413, while EU sites require EN ISO 20345 (with a "S1" to "S3" safety grade).

Industry-Specific Compliance

- Mining: Look for MSHA approval (ventilation for underground gases).

- Energy: NFPA 70E certification for arc flash protection.

Beyond Protection: Ergonomics and Long-Term Wearability

Anti-Slip Outsoles for Oil-Rich Environments

TPU soles dominate in oil/gas due to:

- Microgrooves that channel liquids away.

- Abrasion resistance, lasting 2–3× longer than standard rubber in chemical exposure.

Anti-Fatigue Technology in High-Mobility Jobs

For nurses or factory workers:

- Cushioned midsoles reduce joint stress during 10,000+ daily steps.

- Rockered soles promote natural foot motion, cutting fatigue by ~20% (per Journal of Occupational Ergonomics).

Upgrade Your Safety Footwear with 3515

Distributors and bulk buyers: Partner with 3515 to source boots engineered for your industry’s hazards—from ASTM-compliant toe caps to EH-rated insulation. Let’s reduce workplace injuries without sacrificing comfort.

Did we miss a critical feature for your sector? Explore our range to find your match.

Products You Might Be Looking For:

Explore customizable safety footwear for workplace protection

Related Products

- Wholesale Customizable Suede Safety Boots - Puncture-Proof with Velcro Closure

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Athletic Safety Shoes with Dial Closure & Steel Toe for Wholesale & Custom Manufacturing

- Wholesale Mesh Steel Toe Safety Shoes with Dial Closure Factory Production

- Durable Mid-Cut Tactical Boots for Wholesale & Private Label

Related Articles

- How to Choose Work Boot Materials for Maximum Safety and Durability

- How Safety Work Boots Engineer Protection: Features and Standards for Targeted Hazard Mitigation

- Work Boots vs. Western Boots: How to Choose the Right Footwear for Labor Safety

- How to Choose Work Boots That Match Your Job's Safety Demands

- How to Choose Work Boots That Match Your Industry's Safety Needs