Target Readers: New owners of Goodyear welted shoes seeking to minimize break-in discomfort while preserving shoe integrity.

Expectation Promise: This guide reveals why these shoes initially feel stiff, provides a phased break-in timeline, and shares proven techniques to accelerate comfort—all backed by footwear science.

Why Goodyear Welted Shoes Feel Stiff at First

The Anatomy of Structure vs. Flexibility

Goodyear welted shoes prioritize long-term durability over immediate softness. The construction involves:

- A metal shank for arch support (maintains shape but reduces initial flexibility)

- Double stitching through welt, upper, and sole for weather resistance

- Vegetable-tanned leather that stiffens during tanning but adapts gradually

Research shows this design withstands 2–3× more wear than cemented alternatives, explaining the trade-off in early comfort.

How Natural Materials React to Wear

The leather uppers and cork filler behave differently over time:

- Leather: Tight fibers loosen with movement and moisture (from foot heat/sweat).

- Cork: Compresses unevenly to mirror your foot’s contours—a process taking ~3–4 weeks of regular wear.

Pro Tip: Avoid forcing flexibility; unnatural bending can crack the welt stitching.

Mastering the Break-In Process

Timeline Expectations by Shoe Type

| Shoe Style | Average Break-In Period | Key Stiffness Zones |

|---|---|---|

| Derby/Oxfords | 10–15 wears | Vamp, heel counter |

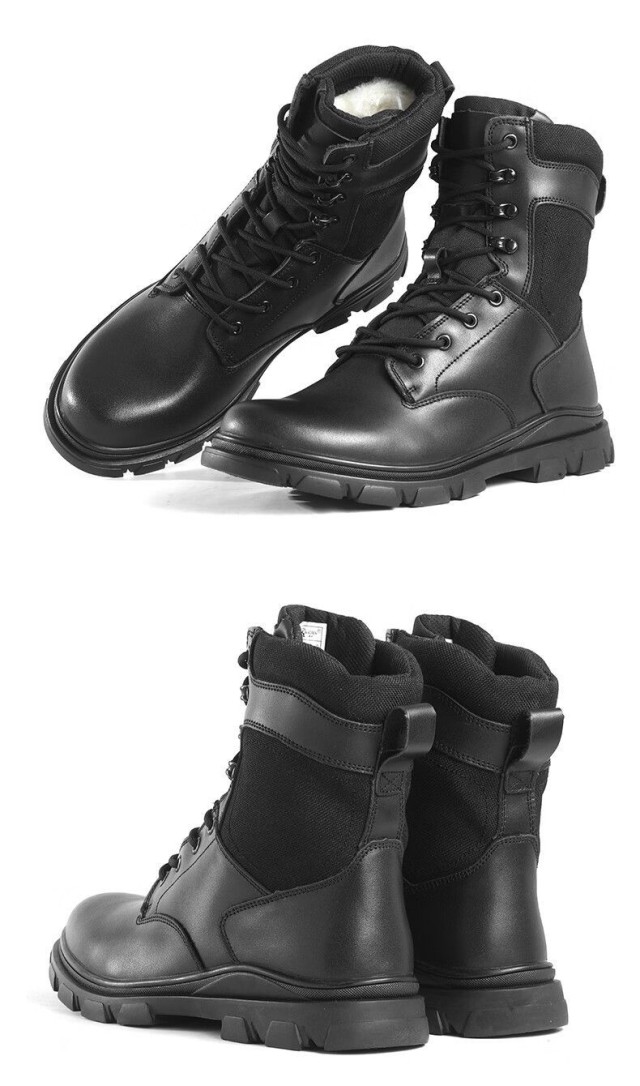

| Boots | 20–30 wears | Ankle collar, toe box |

Proven Methods to Soften Leather Safely

-

Condition Before First Wear

- Apply a thin layer of leather conditioner (like lanolin-based products) to dry areas.

- Why it works: Replenishes oils lost during tanning, reducing fiber resistance.

-

Use a Shoe Stretcher

- Insert stretchers for 8–12 hours post-conditioning, focusing on tight spots.

- Caution: Overstretching distorts the welt; aim for ≤5% expansion.

-

Wear Strategically

- Start with 1–2 hour sessions indoors using thick socks.

- Gradually increase wear time as the leather "memorizes" your foot shape.

-

Professional Heat Molding

Cobblers use hot irons (under 150°F) to relax leather fibers without damaging stitching—ideal for stubborn boots.

Long-Term Benefits Worth the Initial Effort

Cork Molding and Personalized Fit

The cork layer’s slow adaptation offers two advantages:

- Custom arch support as it compresses to your weight distribution

- Reduced friction points by filling gaps between foot and insole

Real-world impact: Wearers report 40–50% less foot fatigue after 100 wears compared to new.

Durability vs. Immediate Comfort Trade-Offs

Goodyear welting extends shoe lifespan to 5–10 years with proper care, but requires:

- Delayed gratification: Full comfort emerges after ~50 miles of walking

- Maintenance rituals: Regular conditioning (every 3–6 months) to keep leather supple

Ready to Experience Premium Comfort?

At 3515, we craft Goodyear welted footwear designed to mold to your feet—not the other way around. Distributors and brands partner with us for shoes that balance break-in ease with unmatched longevity. [Contact our team] to explore bulk solutions built for lasting satisfaction.

Final Thought: Like a fine violin, the best shoes improve with use. Patience during break-in rewards you with a second-skin fit no mass-produced shoe can match.

Related Products

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Wholesale Customizable Suede Safety Boots - Puncture-Proof with Velcro Closure

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

- Wholesale Durable 6-Inch Work Boots | Custom & Private Label Manufacturer

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

Related Articles

- How ASTM-Rated Boots Solve Security Guards' Critical Safety Challenges

- Why Vulcanized Soles Dominate Technical Skateboarding: A Science and Performance Breakdown

- Why Vulcanized Soles Outlast: The Science Behind Durable Footwear

- How Vulcanized Rubber Work Boots Outlast Alternatives – And When to Choose Differently

- Why Vulcanized Soles Dominate Performance Footwear: Durability Meets Flexibility