Every year, workplace foot injuries cost industries millions in lost productivity. The right safety footwear doesn’t just comply with regulations—it actively neutralizes environmental threats through targeted engineering. Here’s how advanced designs protect workers where standard boots fail.

Heat Resistance in Foundries and Welding: Beyond Basic Protection

Foundry workers face molten metal splashes exceeding 1,000°C, while welders confront sparks and radiant heat. Generic leather boots char under these conditions, but purpose-built footwear uses:

- Multi-layer insulation: Heat-resistant membranes (like aluminized materials) reflect radiant energy while allowing breathability

- ASTM F2413-2005 compliant outsoles: Withstand conductive heat transfer from hot surfaces

- Seamless designs: Eliminate stitching weak points where embers could penetrate

Did you know? ASTM testing shows specialized foundry boots can resist direct flame contact for over 60 seconds—critical when accidental spills occur.

Insulation and Traction in Cold or Slippery Environments

Meatpacking plants (-30°C freezers) and oil rigs (ice-coated platforms) demand footwear that combats both temperature and slip hazards:

- Thermal barriers: Aerogel linings provide insulation thinner than traditional Thinsulate™ while blocking moisture

- Arctic-grade rubber: Remains flexible below -40°C to prevent sole cracking

- Micro-stud patterns: Ice-specific treads create 40% better grip than standard lug soles

These features prevent cold stress injuries while reducing fall-related incidents—a leading cause of offshore worker fatalities.

Material Innovations Driving Industry-Specific Safety

Asphalt/Paving: Tackling Molten Surfaces and Compression Risks

Road crews face two invisible threats:

- 300°F+ asphalt that melts conventional soles

- 10,000+ lbs of roller compression forces

Modern solutions include:

- Proprietary polyurethane (PU) outsoles: Resist heat deformation 3x longer than rubber while repelling tar

- Wide-base designs: Distribute weight to reduce crushing injuries by up to 50%

- Vented tongues: Release trapped heat without compromising protection

Mining: Puncture Resistance and Chemical Exposure Solutions

Underground mines present unique challenges:

✔ Carbon fiber shanks: Stop nails and rebar from penetrating, yet weigh 70% less than steel

✔ Electrically dissipative materials: Prevent static sparks in coal seams

✔ Acid-resistant coatings: Protect against battery spills in tunnel vehicles

Field tests show ballistic-fabric reinforced soles can withstand 250+ psi puncture forces—vital when working around discarded mining equipment.

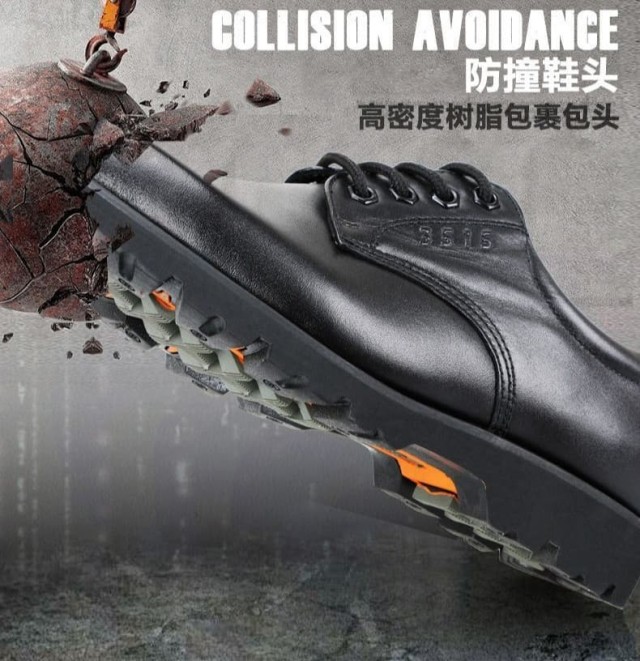

Engineered for Your Industry

3515’s safety footwear solutions transform workplace hazards into manageable risks. Whether you’re sourcing for foundry teams needing heat deflection or mining crews requiring chemical-proof boots, our manufacturing expertise delivers protection that adapts to your environment’s worst conditions.

Protect your workforce with science-backed designs—connect with our specialists to match your hazard profile with precision-engineered footwear.

Products You Might Be Looking For:

View heat-resistant work boots for foundries

Explore customizable safety footwear for industrial hazards

Related Products

- Wholesale Customizable Suede Safety Boots - Puncture-Proof with Velcro Closure

- Wholesale Durable Camo Canvas Shoes with High-Traction Rubber Soles

- Durable Mid-Cut Tactical Boots for Wholesale & Private Label

- Wholesale Durable Mid-Cut Tactical Boots for Custom & Private Label Brands

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

Related Articles

- Steel Toe Work Boots: Balancing Safety and Comfort for Demanding Jobs

- How to Choose Work Boots That Match Your Job Demands and Safety Needs

- Matching Men’s Work Shoe Safety Technologies to Workplace Hazards

- Work Boots vs. Western Boots: How to Choose the Right Footwear for Labor Safety

- How to Extend Work Boot Lifespan: Science-Backed Care for Safety & Savings