When officers suit up for duty, their footwear isn't just an accessory—it's mission-critical equipment. Every component, from the upper materials to the outsole treads, is engineered to address the unique physical demands and environmental challenges faced in law enforcement. This article breaks down the science behind tactical footwear design and how it supports officer safety and performance.

The Anatomy of Police Footwear

Police boots must withstand prolonged wear, unpredictable terrain, and extreme conditions while keeping officers agile. Here’s how each component contributes to tactical readiness.

Upper Materials: Balancing Durability and Mobility in High-Stress Scenarios

The upper part of police footwear faces constant abrasion, moisture, and flexing. Two primary materials dominate the market:

-

Leather (especially full-grain):

- Molds to the foot over time, reducing hotspots during long shifts.

- Naturally breathable, minimizing odor buildup.

- Historically favored for its ruggedness, though modern synthetics now rival its durability.

-

Synthetic composites:

- Lighter weight (critical for foot fatigue prevention).

- Often incorporate waterproof membranes (e.g., Gore-Tex) without sacrificing flexibility.

- Require less break-in time compared to traditional leather.

Key Takeaway: Modern advancements have narrowed the gap between leather and synthetics. Fit and task-specific features (e.g., waterproofing) now matter more than material alone.

Midsole Technology: Combatting Foot Fatigue During Extended Shifts

A 12-hour shift on hard pavement demands midsoles that absorb shock without losing stability. Police footwear leverages:

- Dual-density foam: Firmer foam along the arch for support, softer foam in the heel for impact absorption.

- Thermoplastic urethane (TPU) shanks: Lightweight plates that reduce strain on the plantar fascia.

- Ergonomic footbeds: Contoured to distribute pressure evenly, reducing hotspots.

Did you know? Research shows officers walk 4–6 miles per shift, often on unforgiving surfaces like concrete. A well-engineered midsole can reduce fatigue-related injuries by over 30%.

Outsole Engineering: Traction and Protection on Unpredictable Terrain

Slipping during a pursuit or losing footing on wet stairs isn’t an option. Police outsoles prioritize:

- Multi-directional lugs: Deep treads that grip loose gravel, mud, and slick surfaces.

- Oil-resistant rubber: Maintains traction in urban environments (e.g., gas stations, parking lots).

- Puncture-resistant layers: Thin but tough materials (e.g., Kevlar®) to shield against nails or broken glass.

Pro Tip: Look for outsoles with a "Vibram" or similar certification—these meet rigorous slip-resistance standards.

Beyond the Basics: Industry Standards and Innovations in Tactical Footwear

Leading manufacturers now integrate:

- ANSI/ASTM ratings: Standards for impact protection (e.g., metatarsal guards) and electrical hazard resistance.

- 3D-printed components: Customizable arch support for officers with plantar fasciitis.

- Climate-adaptive designs: Ventilation for desert patrols or insulated liners for winter operations.

The future? Smart boots with embedded sensors to monitor gait abnormalities—preventing injuries before they occur.

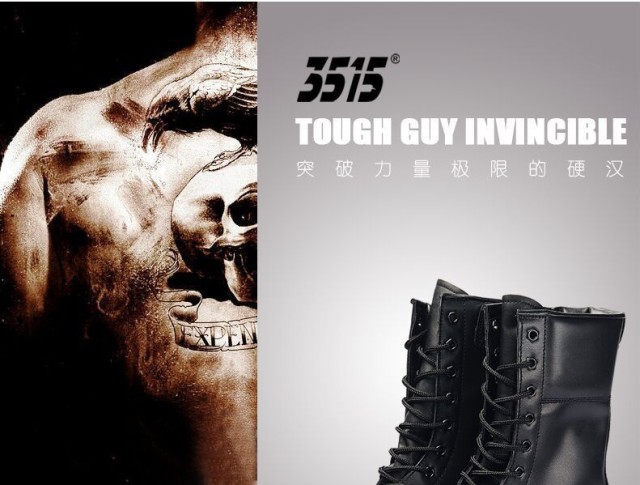

Step Into Superior Tactical Footwear with 3515

For distributors and brand owners seeking reliable, high-performance police footwear, 3515 combines decades of manufacturing expertise with cutting-edge innovations. Our range includes ANSI-compliant designs engineered for the realities of law enforcement—because when officers move with confidence, communities stay safer.

Ready to equip your clients with footwear that stands up to the job? Partner with 3515 to access bulk solutions tailored to tactical needs.

Related Products

- Wholesale Customizable Suede Safety Boots - Puncture-Proof with Velcro Closure

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

- Wholesale Durable Camo Canvas Shoes with High-Traction Rubber Soles

- Wholesale Classic Leather Lace-Up Ankle Boots for Brand Manufacturing

- Wholesale High-Traction Camo Boots - Custom Manufacturer for Brands

Related Articles

- How to Choose Work Boots That Match Your Industry's Safety Needs

- How to Choose Work Boots That Match Your Job Demands and Safety Needs

- Work Boots vs. Western Boots: How to Choose the Right Footwear for Labor Safety

- How to Choose Work Boots That Match Your Job's Safety Demands

- Matching Men’s Work Shoe Safety Technologies to Workplace Hazards