When every second counts, motorcycle police boots must deliver uncompromising protection without sacrificing mobility. These specialized boots integrate advanced materials science with ergonomic design to meet the rigorous demands of law enforcement. Let’s dissect the engineering behind their critical features.

Anatomy of Protection

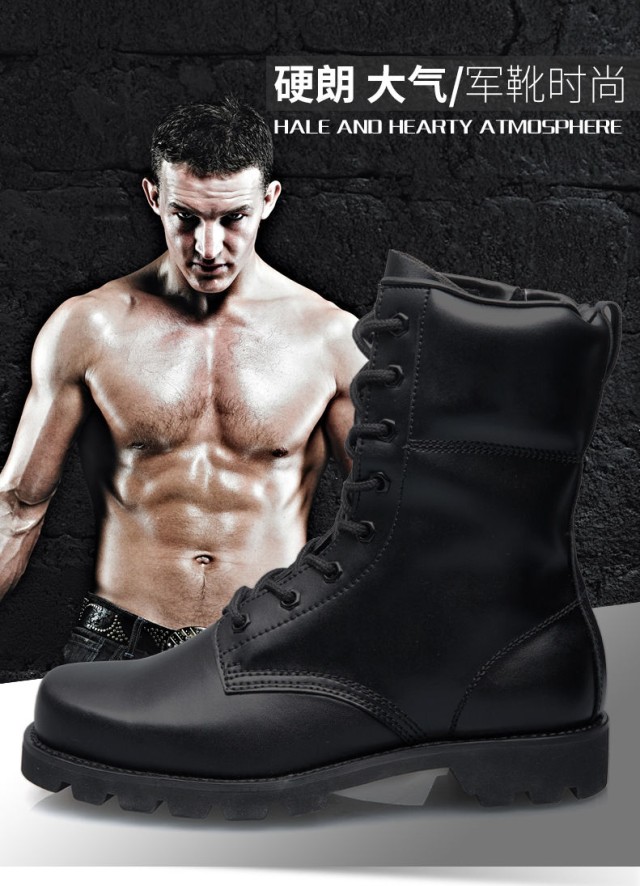

High-Gloss Leather: Beyond Aesthetic Polish

The mirror-like finish on motorcycle police boots isn’t just for visual professionalism—it’s a functional barrier. Full-grain leather, treated for high abrasion resistance, withstands road debris and crash impacts. Research shows that thick leather uppers can reduce friction burns by over 70% compared to synthetic materials.

Key benefits:

- Weatherproofing: Polymer coatings repel water and oil spills.

- Structural Integrity: Reinforced stitching prevents seam failure during high-stress maneuvers.

Rigid Sole Architecture: Impact vs Flexibility

Balancing rigidity and flexibility is a core challenge. Boot soles must:

- Resist Puncture: ASTM F-2412-2005 certified soles embed steel or composite plates to stop nails, glass, or sharp objects.

- Absorb Vibration: Multi-density rubber compounds dampen engine vibrations, reducing long-term joint fatigue.

- Optimize Grip: Deep-lug outsoles maintain traction on wet roads and oily surfaces.

Design Insight: Military-grade heel counters (often thermoplastic) prevent ankle rolls during sudden dismounts.

Ergonomic Combat Readiness

Ankle Locking Mechanisms

A 360° support system combines:

- Internal Stabilizers: Molded plastic or carbon fiber inserts limit lateral movement.

- External Straps: Adjustable closures customize fit for varied calf sizes.

Studies indicate proper ankle support reduces sprain risks by approximately 60% during foot-down stops.

Heat Resistance Thresholds

Boots face twin thermal threats:

- Exhaust Proximity: Heat-resistant liners (e.g., aramid fibers) shield against 500°F+ pipe temperatures.

- Ambient Heat: Perforated tongues enhance airflow without compromising protection.

Uniform Integration Science

Breeches Interface Design

Boots seamlessly integrate with tactical uniforms via:

- Extended Collars: Prevent debris entry while accommodating knee guards.

- Low-Profile Zippers: Enable quick gear changes without snagging.

Quick-Don Technology

Speed matters during emergencies. Features like:

- Pull Loops: Facilitate one-handed wearing.

- Elasticated Panels: Accommodate varying leg dimensions.

Why Trust 3515 for Tactical Footwear?

With decades of expertise, 3515 delivers boots that meet ASTM and occupational safety standards. Our designs prioritize:

✅ Durability: Industrial-grade materials for 10,000+ hours of use.

✅ Comfort: Engineered insoles reduce fatigue during 12-hour shifts.

✅ Customization: Bulk orders tailored to agency specifications.

Upgrade your fleet’s safety today—partner with 3515 for boots built to protect those who protect us.

Related Products

- Durable Moc Toe Wedge Sole Work Boots for Wholesale and Private Label

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Moc-Toe Wedge Work Boots | Wholesale Manufacturing for Brands

Related Articles

- Composite Toe Boots: The Modern Safety Solution for Demanding Work Environments

- How Military Boot Sole Engineering Solves Tactical Challenges in Extreme Environments

- How Material Science and Construction Define Abrasion Resistance in Work Boots

- Moc Toe Safety Boots: When Style Meets Workplace Protection

- How to Choose Between Composite and Steel Toe Boots for Optimal Safety