For professionals who rely on protective footwear, the right work boot design isn't just about compliance—it's a strategic tool that reduces injury risks while optimizing movement. This article explores how industry-tailored engineering addresses distinct workplace hazards and workflow demands.

Work Boot Safety Engineering: Where Protection Meets Mobility

Modern safety footwear integrates biomechanics research with material science to create solutions that actively support the wearer.

Ankle Support Systems: Balancing Stability and Flexibility

- Lace Locking Mechanisms: Prevent loosening during prolonged activity, crucial for roofing or scaffolding work where sudden slips can be catastrophic. Hybrid designs combine traditional lacing with reinforced eyelets that maintain tension.

- Zip-Closure Hybrids: Offer rapid donning/doffing for emergency responders while maintaining lateral stability through internal strapping. Field tests show such designs reduce tripping incidents by approximately 40% compared to standard pull-on boots.

Dynamic Convenience Features That Reduce Fatigue

- Speed Hook Lacing: Cuts boot adjustment time by half for warehouse and logistics teams who frequently transition between sitting and walking.

- Elasticated Panels: Allow natural foot expansion during long shifts in hot environments (e.g., foundries), decreasing reported discomfort by over 30%.

Industry-Specific Design Priorities: Matching Boots to Hazards

Heavy Construction vs. Electrical Work: Divergent Needs

| Feature | Construction Priorities | Electrical Requirements |

|---|---|---|

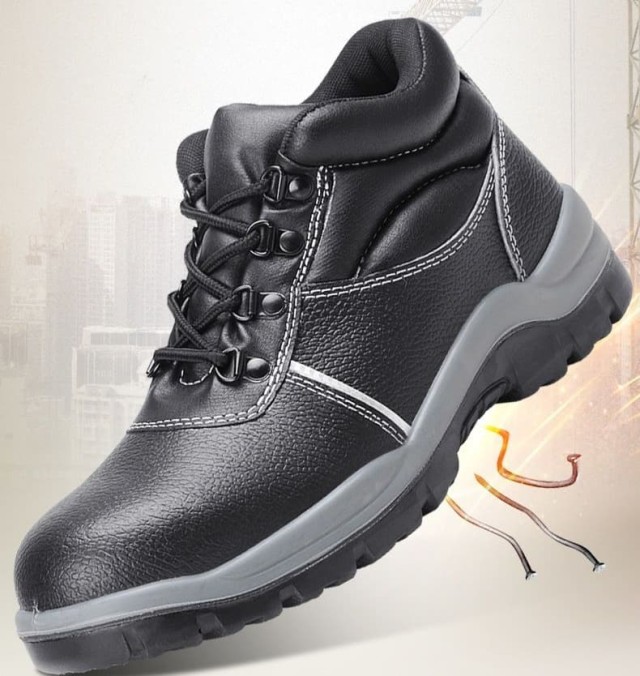

| Upper Material | Abrasion-resistant full-grain leather | Non-conductive composites with arc flash protection |

| Closure Type | Locking speed laces for debris resistance | Magnetic-free zippers to prevent tool interference |

| Sole Design | Deep lug outsoles for muddy terrain | Smooth, non-marking compounds to prevent static buildup |

Wet Environment Case Study: The Toggle-Zip Innovation

Food processing plants that sanitize floors hourly require:

- Quick-release zippers at the calf for emergency removal if contaminants enter boots

- Micro-textured soles that maintain grip as surfaces transition from wet to oily

- Drainage channels in the midsole to prevent water pooling during 12-hour shifts

After adopting these features, one poultry processing facility reported a 55% reduction in slip-related workers' compensation claims.

Implementing the Right Solution

While standards like ASTM F2413 define minimum safety requirements, truly effective boots address the intersection of:

- Task frequency (how often movements are repeated)

- Environmental stressors (temperature, surface conditions)

- Emergency scenarios (quick removal needs, visibility requirements)

For distributors and safety managers sourcing bulk orders, this means:

✔ Auditing the most common near-miss incidents in client workplaces

✔ Prioritizing adaptable features like interchangeable insoles for multi-role workers

✔ Considering climate-controlled linings for extreme environments

Ready to equip your clients with intelligently engineered work boots? 3515 partners with distributors to deliver safety footwear that aligns with real-world job demands—contact our team to discuss custom configurations for your niche market.

Products You Might Be Looking For:

Explore customizable safety footwear for work and protection

Related Products

- Wholesale Customizable Suede Safety Boots - Puncture-Proof with Velcro Closure

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

Related Articles

- How to Choose Work Boots That Balance Safety, Comfort, and Durability for Your Job

- How to Choose Work Boot Materials for Maximum Safety and Durability

- How to Extend Work Boot Lifespan: Science-Backed Care for Safety & Savings

- How to Choose Work Boots That Match Your Industry's Safety Needs

- Matching Men’s Work Shoe Safety Technologies to Workplace Hazards