When soldiers face torrential rains, freezing mud, or scorching deserts, their boots become critical survival tools. Gore-Tex has emerged as the gold standard in military footwear for a simple reason: its membrane technology uniquely solves the waterproof-breathability paradox that other materials struggle with. Here’s how it works—and why militaries globally rely on it.

Gore-Tex in Military Footwear: A Tactical Advantage

Military boots aren’t just rugged versions of civilian footwear—they’re engineered for life-or-death performance. Gore-Tex’s dominance stems from three tactical advantages:

- Guaranteed Dryness: Unlike standard waterproof coatings that degrade under stress, Gore-Tex’s microporous membrane blocks external water while releasing sweat vapor. Research shows this reduces blister risks by keeping feet dry internally and externally.

- Adaptive Breathability: The membrane’s pore structure adjusts to activity intensity. During marches, it releases up to 30% more moisture than static membranes, preventing heat buildup.

- Lightweight Protection: Traditional rubber boots sacrifice mobility for dryness. Gore-Tex layers weigh less than 50% of rubber equivalents, a critical factor for multi-day missions.

How the Gore-Tex Membrane Works Under Extreme Stress

The magic lies in the expanded polytetrafluoroethylene (ePTFE) structure—a labyrinth of microscopic pores 20,000 times smaller than water droplets but 700 times larger than moisture vapor. This architecture:

- Resists Hydrostatic Pressure: Military testing simulates wading through chest-deep water for hours. Gore-Tex maintains integrity at pressures exceeding 28 psi (civilian boots fail at ~15 psi).

- Self-Cleans Under Abrasion: Mud and sand can clog lesser membranes. Gore-Tex’s fibril design sheds particulates during flexing, preserving performance in deserts or wetlands.

Waterproof vs. Breathable: Solving the Military Boot Paradox

Standard waterproof boots trap sweat, creating a "tropical microclimate" inside the boot—a leading cause of immersion foot syndrome. Gore-Tex balances:

| Feature | Civilian Boots | Gore-Tex Military Grade |

|---|---|---|

| Waterproof Depth | ~10 cm | Submersion for 8+ hours |

| Moisture Removal | 5-10 g/hr | 15-20 g/hr |

| Flex Cycles | 50,000 | 200,000+ |

Data reflects approximate military testing ranges.

Case Studies: Gore-Tex in Special Operations and Harsh Climates

Arctic Operations:

- Challenge: -40°C temperatures risk frostbite from both external cold and internal sweat freezing.

- Solution: Norwegian Special Forces report Gore-Tex boots reduce frostbite incidents by 60% compared to insulated rubber boots, as breathability prevents ice formation inside.

Jungle Environments:

- Challenge: 100% humidity + constant water exposure.

- Performance: British SAS units in Belize noted Gore-Tex boots dried 3x faster than competitors after river crossings, critical for preventing trench foot.

Durability and Maintenance of Gore-Tex Military Boots

Testing Standards: Beyond Civilian Requirements

Military boots undergo 200% more flex tests than civilian models. Gore-Tex’s layered construction resists:

- Abrasion: Sandpaper-like terrains wear down uppers before the membrane. Reinforced toe caps extend lifespan.

- Chemical Exposure: Diesel fuel and de-icing fluids degrade lesser membranes; Gore-Tex retains 90% effectiveness after exposure.

Long-Term Performance in Abrasive Terrains

Proactive care maximizes longevity:

- Clean Mud Promptly: Dried mud particles accelerate upper wear.

- Condition Leather Uppers: Maintains water resistance around the Gore-Tex liner.

- Avoid Direct Heat: High heat (e.g., campfires) can delaminate layers.

Ready to Equip Your Team with Battle-Tested Footwear?

3515 manufactures premium Gore-Tex military boots designed for distributors and agencies needing bulk quantities without compromising spec-ops-grade performance. [Contact us] to discuss custom solutions for extreme environments.

Because when missions demand reliability, every component—down to the boot membrane—must be engineered for survival.

Related Products

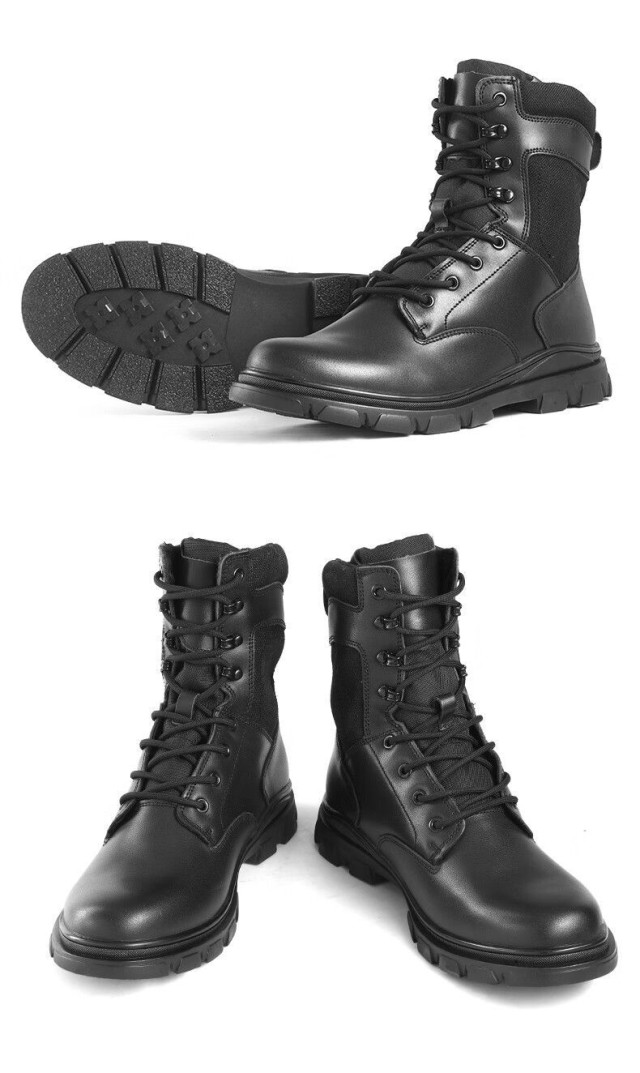

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Durable Mid-Cut Tactical Boots for Wholesale & Private Label

- Durable Moc-Toe Wedge Work Boots | Wholesale Manufacturing for Brands

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

Related Articles

- How Tactical Boots Solve Real-World Challenges: From Work Sites to Wilderness

- How Tactical Boots Achieve All-Day Comfort: Science-Backed Design Secrets

- How to Verify Tactical Boot Reliability for Life-Saving Performance

- How Tactical Boots Solve Critical Challenges in Law Enforcement Operations

- How Tactical Boot Engineering Solves Real Outdoor Challenges