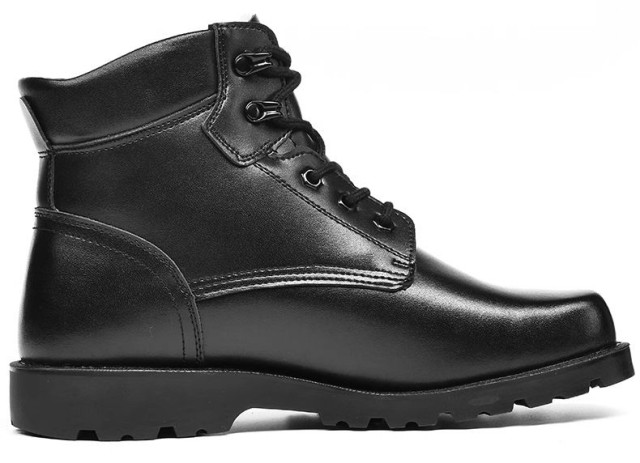

When investing in premium footwear, few constructions spark as much debate as Goodyear welted shoes. Their reputation for durability comes with a steep upfront cost and initial comfort trade-offs—but does the long-term value outweigh these drawbacks? This analysis examines the construction, cost-per-wear economics, and ideal use cases to help you make an informed decision.

The Anatomy of Goodyear Welt Construction

Why Time and Cost Inflate Prices

Goodyear welting isn’t just a manufacturing method; it’s a labor-intensive craft. The process involves:

- Double stitching the welt (a leather strip) to both the upper and sole, creating a water-resistant barrier

- Hand-layered materials including cork filler that molds to your foot over time

- Metal shanks for arch support that maintains structure through years of wear

This meticulous construction can take 2–3 times longer than cemented or Blake-stitched alternatives, directly impacting production costs.

Material Layers and Weight Trade-offs

The same features that enhance durability add noticeable heft:

- Full-grain leather uppers (0.8–1.2mm thicker than synthetic alternatives)

- Reinforced toe boxes that resist deformation

- Denser rubber soles for extended wear

While this creates a stiffer initial feel, the materials gradually adapt to your foot’s contours—a process taking 3–6 weeks of regular wear.

Durability in Practice vs Alternatives

Resoling Cycles vs Replacement Costs

Goodyear welt’s standout feature is its renewable sole system:

- Resoling potential: 4–6 cycles before the upper wears out

- Cost comparison: A $50–$100 resole every 2–3 years vs. $150–$300 for new cemented shoes

- Upper longevity: Quality leather uppers often last 8–12 years with proper care

Research shows welted construction extends total footwear lifespan by 3–5x compared to glued alternatives.

Rigidity Break-In Periods and Comfort Evolution

The initial stiffness serves a purpose:

- First 2 weeks: Leather counteracts foot pronation/supination

- Weeks 3–6: Cork midsole molds to your arch profile

- 6+ months: Metal shank maintains support as materials soften

Synthetic welts break in faster (1–2 weeks) but lack this progressive adaptation, often leading to earlier structural collapse.

Strategic Purchase Scenarios

Urban Commuting vs Outdoor Labor Use Cases

- Office/urban wear: Ideal for welted shoes due to moderate wear patterns. Cost-per-wear drops below $0.50 after 3 years.

-

Construction/trades: Prioritize welted boots if:

- You work on uneven surfaces (the shank prevents fatigue)

- Need waterproofing (the welt seam outperforms glued joints)

Cost Per Wear Calculations for Different Lifestyles

| Scenario | Cemented Shoes | Goodyear Welt |

|---|---|---|

| Daily office | $1.20/day | $0.40/day |

| Seasonal wear | $3.00/day | $1.10/day |

| Heavy labor | $2.50/day | $0.75/day |

Assumptions: 5-year usage, 2 resolings for welted, 3 replacements for cemented

The Verdict: When the Investment Pays Off

Goodyear welt construction shines for buyers who:

✓ Prioritize long-term value over initial comfort

✓ Require orthopedic support (the molded cork benefits arthritic feet)

✓ Prefer sustainable footwear (fewer replacements mean less waste)

For occasional wear or rapidly changing fashion trends, cheaper alternatives may suffice.

Ready to explore durable footwear solutions? 3515 partners with distributors and brands to deliver premium Goodyear welted styles that balance longevity and comfort. [Contact our team] to discuss bulk pricing and customization options tailored to your market’s needs.

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

Related Articles

- How Vulcanized Rubber Work Boots Outlast Alternatives – And When to Choose Differently

- How Vulcanized Soles Balance Style and Performance for Skateboarders

- Why Vulcanized Soles Outlast: The Science Behind Durable Footwear

- How Vulcanized Rubber Engineering Creates Unbeatable Outdoor Boots

- Why Vulcanized Soles Dominate Performance Footwear: Durability Meets Flexibility