Stuck with work boots that pinch, rub, or cramp your feet? Before resigning to a painful shift, try these proven, no-cost solutions to redistribute pressure, cushion hotspots, and make it through the day.

Triage Your Discomfort

Mapping Pain Zones for Targeted Fixes

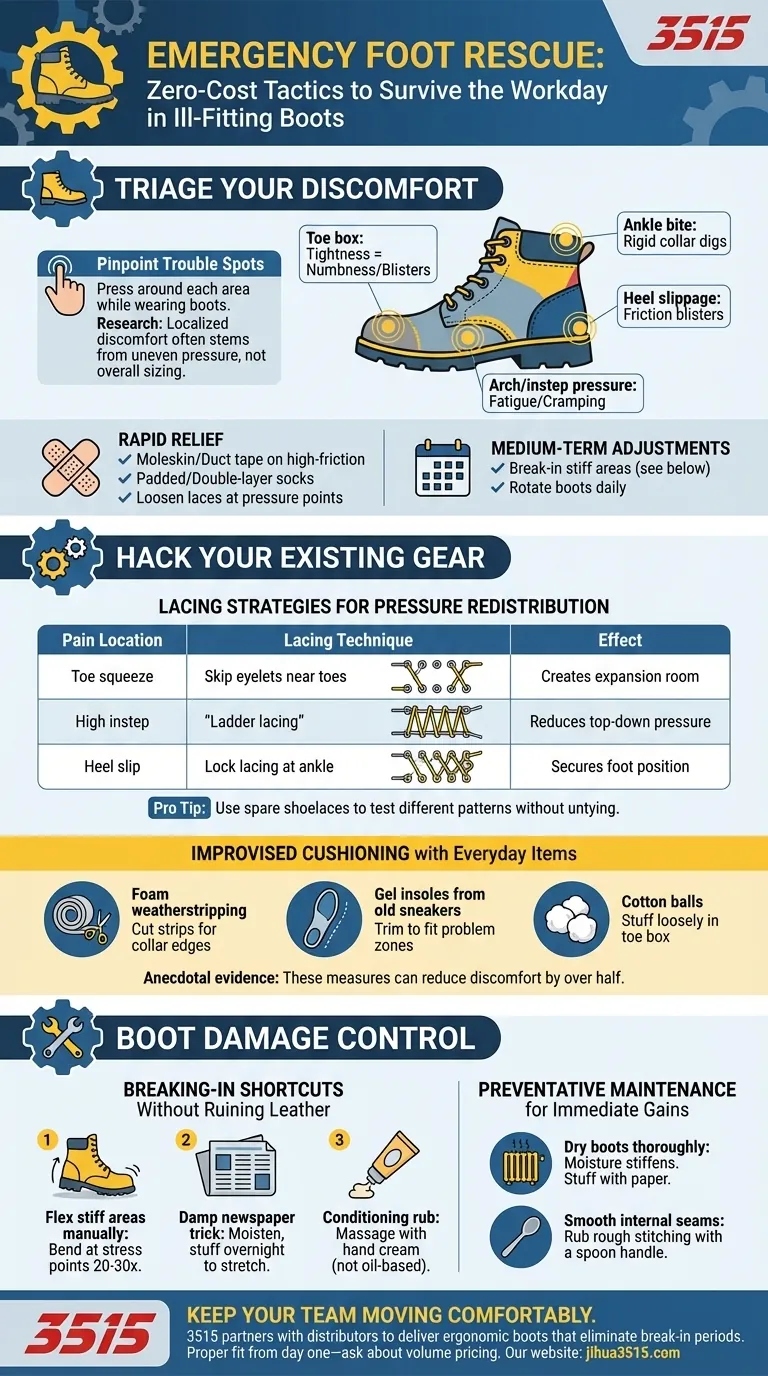

Identify where your boots hurt most:

- Toe box: Tightness here causes numbness or blisters

- Heel slippage: Leads to friction blisters at the back

- Arch/instep pressure: Creates fatigue and cramping

- Ankle bite: Rigid collar edges dig into skin

Press gently around each area while wearing boots to pinpoint trouble spots. Research shows localized discomfort often stems from uneven pressure distribution rather than overall sizing issues.

Rapid Relief vs. Medium-Term Adjustments

For immediate relief:

✔ Apply moleskin or duct tape to high-friction zones

✔ Use padded socks (or double-layer thin socks)

✔ Loosen laces at pressure points

For ongoing improvement:

✔ Focus on breaking-in stiff areas (see "Boot Damage Control")

✔ Rotate boots daily to reduce repetitive stress

Hack Your Existing Gear

Lacing Strategies for Pressure Redistribution

| Pain Location | Lacing Technique | Effect |

|---|---|---|

| Toe squeeze | Skip eyelets near toes | Creates expansion room |

| High instep | "Ladder lacing" (parallel vertical runs) | Reduces top-down pressure |

| Heel slip | Lock lacing at ankle | Secures foot position |

Pro Tip: Use spare shoelaces to test different patterns without untying your boots mid-shift.

Improvised Cushioning with Everyday Items

- Foam weatherstripping: Cut strips for collar edges

- Gel insoles from old sneakers: Trim to fit problem zones

- Cotton balls: Stuff loosely in toe box for temporary expansion

Anecdotal evidence from warehouse workers shows these stopgap measures can reduce discomfort by over half while waiting for proper footwear replacements.

Boot Damage Control

Breaking-In Shortcuts Without Ruining Leather

- Flex stiff areas manually: Bend boots at stress points 20-30 times when removing them.

- Damp newspaper trick: Lightly moisten newspaper, stuff boots overnight to gently stretch fibers.

- Conditioning rub: Massage leather with hand cream (not oil-based) to soften targeted spots.

Preventative Maintenance for Immediate Gains

- Dry boots thoroughly: Moisture-stiffened leather worsens fit. Stuff with paper to absorb sweat.

- Smooth internal seams: Rub rough stitching with a spoon handle to flatten ridges.

Keep Your Team Moving Comfortably

3515 partners with distributors and bulk buyers to deliver ergonomically designed work boots that eliminate break-in periods. Our manufacturing expertise ensures proper fit from day one—ask about our volume pricing for pain-free workforces.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

Related Articles

- How to Choose Between Steel and Composite Toe Boots for Maximum Safety

- How Steel Toe Boots Deliver Financial and Safety Returns in High-Risk Workplaces

- How to Reduce Steel Toe Boot Risks Without Compromising Workplace Safety

- How Steel Toe Boots Meet Industry Safety Standards and Reduce Workplace Injuries

- Steel Toe Work Boots: Balancing Safety and Comfort for Demanding Jobs