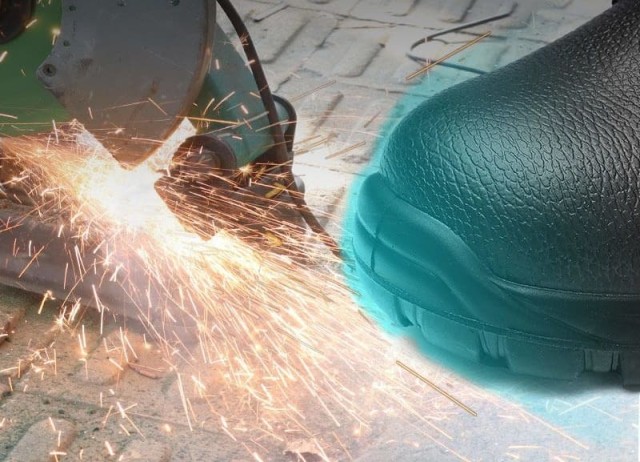

When your job demands safety footwear, the choice between composite and steel toe boots isn’t just about compliance—it’s about matching protection to your specific hazards, environment, and comfort needs. This guide breaks down the key differences, industry-specific recommendations, and long-term value to help you make an informed decision.

Material Science Breakdown: How Composite and Steel Differ

Composite toe boots use advanced materials like fiberglass, carbon fiber, or Kevlar® to create a lightweight, non-metallic protective cap. These materials offer:

- No thermal conductivity: Ideal for extreme temperatures (e.g., freezers or foundries).

- Electrical hazard resistance: Safer for utility workers or those near live wires.

- Lighter weight: Reduces fatigue during long shifts.

Steel toe boots, the traditional choice, provide:

- Higher durability: Better for heavy-impact environments like construction.

- Slimmer profile: Fits more snugly in tight spaces.

- Lower upfront cost: Budget-friendly for high-replacement scenarios.

Did you know? Composite materials can be up to 30% lighter than steel, a game-changer for workers on their feet all day.

Decoding ASTM F2413-18: What the Standards Mean for You

Both toe types meet ASTM F2413-18 standards for impact and compression resistance, but their performance varies:

| Feature | Composite Toe | Steel Toe |

|---|---|---|

| Impact Resistance | Meets ASTM (75 ft-lbs) | Meets ASTM (75 ft-lbs) |

| Compression | Meets ASTM (2,500 lbs) | Meets ASTM (2,500 lbs) |

| Electrical Hazard (EH) | Often rated EH | Rarely rated EH |

Key takeaway: If your workplace requires EH-rated footwear (e.g., electrical utilities), composite toes are the safer bet.

Environmental Suitability: Extreme Temperatures and Electrical Risks

Cold Weather Performance

- Composite: Insulates against cold; won’t freeze to skin in sub-zero temps.

- Steel: Conducts cold, risking discomfort or frostbite in prolonged exposure.

High-Heat Environments

- Composite: Resists heat transfer, unlike steel toes that can overheat.

- Steel: May require heat-resistant liners in foundries or welding shops.

Pro tip: For mixed conditions (e.g., oil rigs or alpine construction), composite toes adapt better to temperature swings.

Beyond Safety: Comfort, Weight, and Longevity Comparisons

Comfort

- Composite: Lighter and often paired with cushioned midsoles.

- Steel: Heavier but offers a firmer fit for precision tasks.

Long-Term Value

- Composite: Higher upfront cost but lasts longer in corrosive environments (e.g., chemical plants).

- Steel: Affordable but may rust or dent over time, requiring earlier replacement.

Have you considered how boot weight affects your productivity? A 10-hour shift in lighter composite boots can reduce leg strain by up to 20%.

Industry-Specific Recommendations

Construction

- Steel toe: Best for heavy machinery zones with crushing risks.

Utilities/Electrical Work

- Composite toe: Essential for EH protection and metal-free security checkpoints.

Oil & Gas

- Composite: Resists sparks and chemicals; won’t corrode like steel.

Warehousing

- Composite: Lightweight for all-day mobility.

Ready to Equip Your Team?

3515 delivers tailored safety footwear solutions for distributors and bulk buyers, ensuring your workforce gets the right protection without compromising comfort. From composite toes for extreme environments to cost-effective steel options, our range meets every hazard and budget.

Contact 3515 today to discuss custom bulk orders—because safety shouldn’t be a one-size-fits-all decision.

Products You Might Be Looking For:

View customizable steel toe work boots

Related Products

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

Related Articles

- How to Choose Safety Footwear That Solves Steel Toe Shoe Problems Without Sacrificing Protection

- Steel-Toe vs. Composite-Toe Boots: How to Choose the Right Safety Footwear for Your Job

- How Steel Toe Shoes Prevent Injuries: The Science Behind Workplace Safety

- Steel Toe Work Boots: Balancing Safety and Comfort for Demanding Jobs

- Matching Men’s Work Shoe Safety Technologies to Workplace Hazards