At its core, composite-toe boots are a better choice for passing through metal detectors because their protective cap is made from non-metallic materials. Unlike steel, materials like carbon fiber, Kevlar, or specialized plastics are not detected by the electromagnetic fields used in standard security screening equipment.

The critical distinction is that while a steel-toe boot will always trigger a metal detector, a composite-toe boot is specifically designed to be "invisible" to them. However, for guaranteed passage, you must ensure the entire boot is certified as non-metallic, as some models may still contain a hidden steel shank.

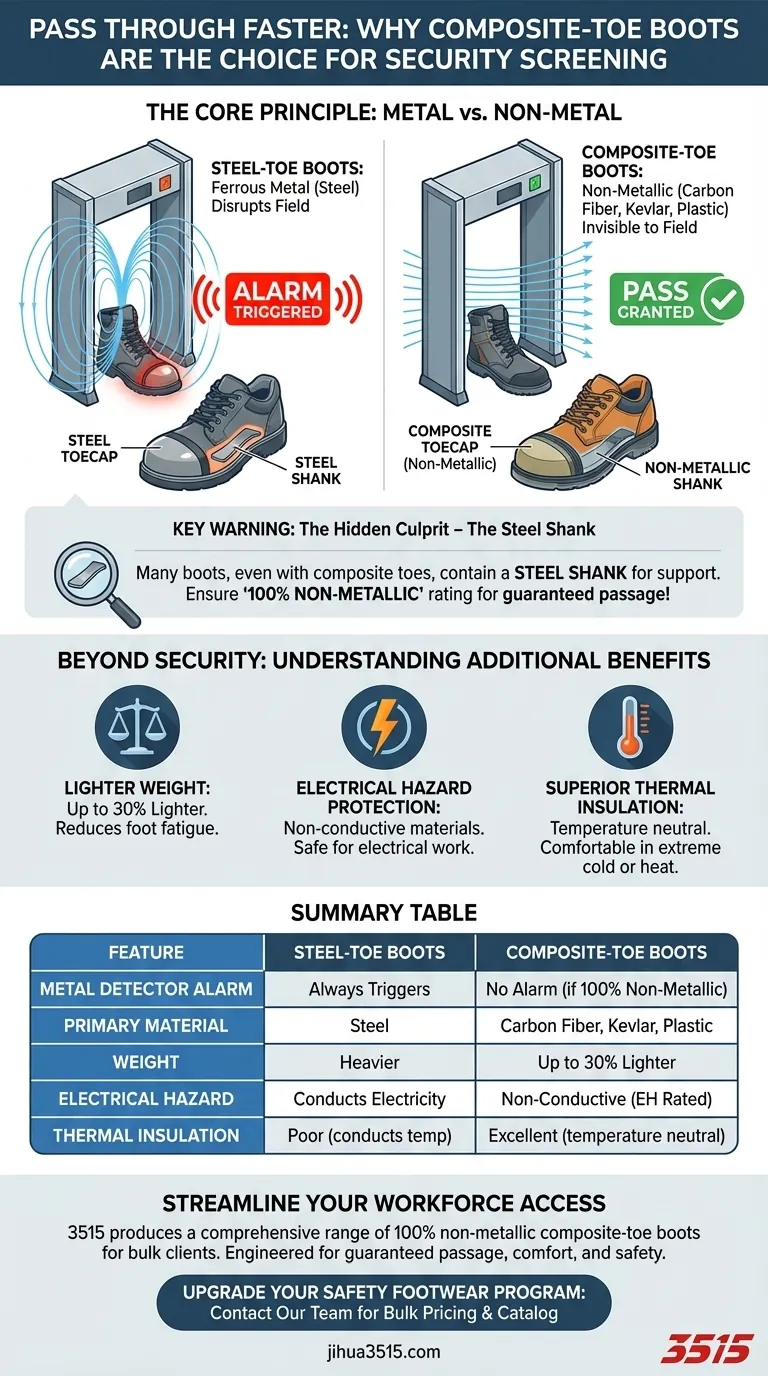

The Core Principle: Metal vs. Non-Metal Construction

The reason one boot triggers an alarm while another doesn't comes down to fundamental material science and how security scanners operate.

How Metal Detectors Work

Standard walk-through metal detectors create an electromagnetic field. When a conductive, ferrous metal like steel passes through this field, it disrupts it, which triggers an alarm.

The Inherent Issue with Steel Toes

A steel-toe boot has a protective cap made from steel. As a ferrous metal, it will consistently and reliably set off a metal detector, requiring the wearer to remove their footwear for screening.

The Advantage of Composite Toes

Composite-toe caps are engineered from a blend of non-metallic materials. These can include carbon fiber, plastic, Kevlar, or fiberglass, all of which do not interact with a metal detector's magnetic field.

Why "Composite Toe" Isn't Always Enough

While the toe cap is the most obvious component, other parts of a boot's construction can cause issues at a security checkpoint.

The Hidden Culprit: The Steel Shank

Many work boots, including some with composite toes, incorporate a steel shank. This is a small, rigid plate embedded in the midsole to provide arch support and stability. If a steel shank is present, the boot will still trigger a metal detector.

The Importance of a "100% Non-Metallic" Rating

To avoid any issues, you must look for boots that are explicitly advertised as "100% Non-Metallic" or "Metal-Free." This certification guarantees that not only the toe cap but also all other hardware, such as the eyelets and shank, are made from non-metallic materials.

Understanding the Trade-offs and Additional Benefits

Choosing composite-toe boots offers several advantages beyond just being friendly to metal detectors, but it's important to understand the complete picture.

Advantage: Lighter Weight

Composite materials are significantly lighter than steel. A composite-toe boot can be up to 30% lighter than its steel-toed equivalent, which reduces foot fatigue over a long workday.

Advantage: Electrical Hazard Protection

Because they contain no metal, composite boots do not conduct electricity. This makes them the superior choice for electricians or anyone working in environments with a risk of electrical hazards.

Advantage: Superior Thermal Insulation

Steel is highly conductive of temperature, making steel-toe boots very cold in winter and hot in summer. Composite materials provide much better thermal insulation, keeping your feet more comfortable in extreme weather conditions.

Consideration: Bulk and Profile

To achieve the same level of impact protection required by safety standards (like ASTM F2413), a composite cap often needs to be slightly thicker or bulkier than a steel one. While this difference is often minimal, it's a factor in the boot's overall profile.

Making the Right Choice for Your Goal

Selecting the right safety boot requires matching its features to your specific work environment and daily tasks.

- If your primary focus is passing through security checkpoints: Choose a boot that is explicitly labeled "100% Non-Metallic" to ensure every component is free of metal.

- If your primary focus is working around live electricity: A composite-toe boot is the only appropriate choice due to its non-conductive properties.

- If your primary focus is all-day comfort and reducing fatigue: The lighter weight and superior thermal insulation of composite boots offer a clear advantage over steel.

Ultimately, choosing a composite-toe boot empowers you to move through secure environments with efficiency while gaining benefits in comfort and specialized safety.

Summary Table:

| Feature | Steel-Toe Boots | Composite-Toe Boots |

|---|---|---|

| Metal Detector Alarm | Always Triggers | No Alarm (if 100% Non-Metallic) |

| Primary Material | Steel | Carbon Fiber, Kevlar, Plastic |

| Weight | Heavier | Up to 30% Lighter |

| Electrical Hazard | Conducts Electricity | Non-Conductive (EH Rated) |

| Thermal Insulation | Poor (conducts temp) | Excellent (temperature neutral) |

Streamline your workforce's access and enhance their safety.

As a large-scale manufacturer, 3515 produces a comprehensive range of 100% non-metallic composite-toe boots for distributors, brand owners, and bulk clients. Our boots are engineered for guaranteed passage through security checkpoints while providing superior comfort, reduced fatigue, and essential electrical hazard protection.

Upgrade your safety footwear program today. Contact our team for bulk pricing and catalog to equip your workforce with the right boots for secure and efficient environments.

Visual Guide

Related Products

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

- Premium Wholesale Tactical Style Safety Shoes Boots with Quick Lacing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- Do safety boots expire? Understand Their True Service Life for Maximum Protection

- What are the basic European safety standard categories for work footwear? A Guide from SB to S5

- What additional safety features do modern safety Wellington boots offer? Enhanced Protection for Hazardous Workplaces

- What are the primary functions of professional safety shoes? Maximize Safety in Water Supply Confined Spaces

- What are the advantages of leather as a material for motorcycle boots? Unmatched Safety & Long-Term Comfort

- Which is better, steel toe or composite toe boots? Match Your Job's Hazards for Optimal Safety

- Why are composite-toe boots suitable for composite manufacturing? The Ideal Safety Solution

- How do complex outsole tread designs in safety shoes work with coated floors? Master Slip Resistance Engineering