Traction in oilfield boots is the critical line of defense against career-ending injuries. In an environment defined by slippery contaminants and unpredictable surfaces, the grip of your outsole is what allows for stability, control, and personal safety. The right traction directly mitigates the constant risk of slips, trips, and falls that are prevalent across drilling sites and production facilities.

The importance of traction goes beyond simply preventing a fall. It is about enabling a worker to maintain solid footing and body control while performing demanding physical tasks on surfaces compromised by oil, mud, and water, making it a non-negotiable pillar of worksite safety.

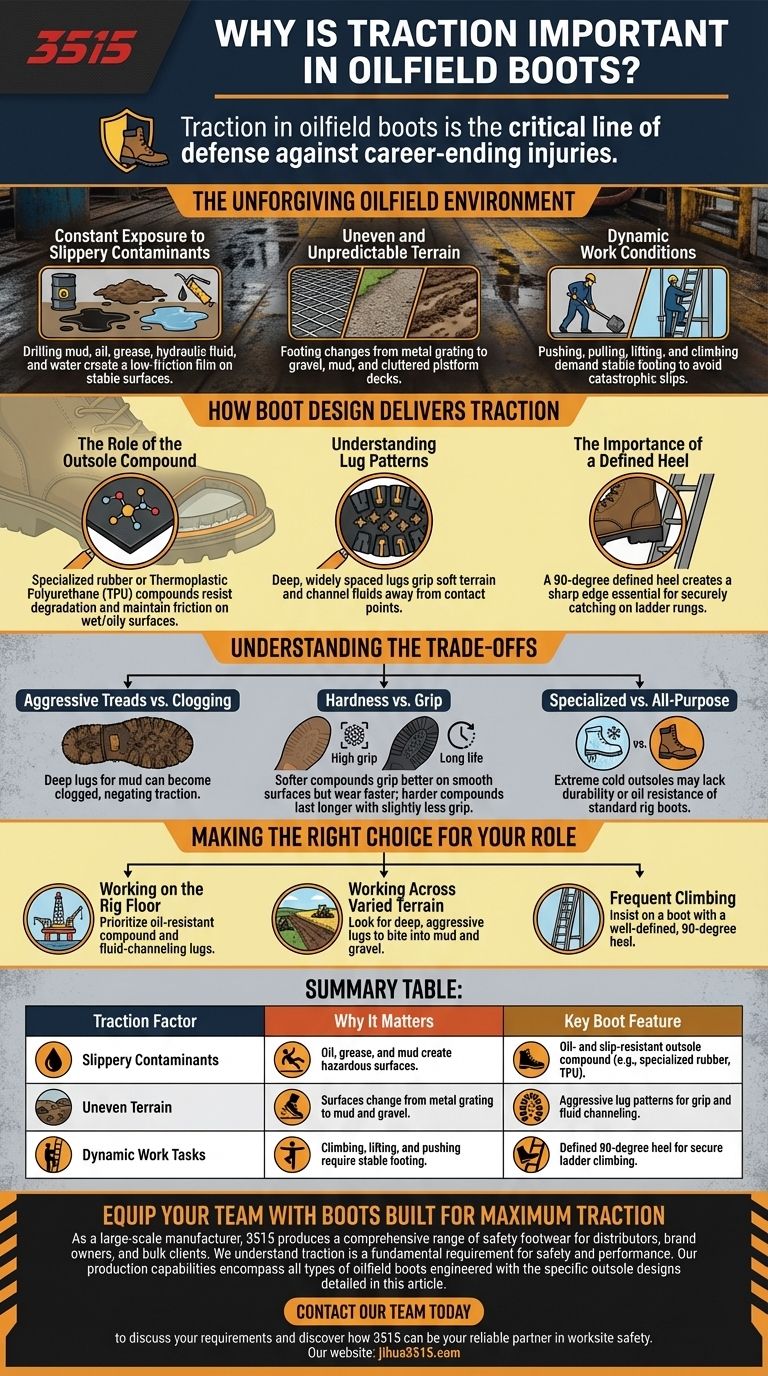

The Unforgiving Oilfield Environment

To understand why traction is paramount, you must first appreciate the unique and hazardous nature of the surfaces involved. Standard work boots are simply not equipped to handle these conditions.

Constant Exposure to Slippery Contaminants

The very nature of oil and gas extraction means surfaces are rarely clean and dry. Workers constantly encounter drilling mud, oil, grease, hydraulic fluid, and water.

These substances create a low-friction film on otherwise stable surfaces like steel decking or concrete, dramatically increasing the risk of a slip.

Uneven and Unpredictable Terrain

An oilfield is a dynamic and rugged environment. Footing can change from one step to the next.

You may be walking across metal grating, gravel lots, mud-caked ground, or cluttered platform decks. Each surface requires a different kind of grip to ensure stability.

Dynamic Work Conditions

Workers are not just standing still; they are pushing, pulling, lifting, and climbing. These tasks demand stable footing to generate force and maintain balance.

A sudden slip while handling heavy equipment or climbing a rig ladder can have catastrophic consequences.

How Boot Design Delivers Traction

Specialized oilfield boots use specific design features to counteract the hazardous conditions on-site. The outsole is the most critical component in this system.

The Role of the Outsole Compound

The material of the outsole is the first line of defense. Most high-quality boots use specialized rubber or Thermoplastic Polyurethane (TPU) compounds.

These materials are engineered to be oil- and slip-resistant, meaning they resist degradation from petrochemicals and are formulated to maintain a high coefficient of friction even on wet or oily surfaces.

Understanding Lug Patterns

The channels and projections on the bottom of the boot are called lugs. Their design is crucial for performance.

Deep, widely spaced lugs provide an aggressive grip on soft terrain like mud and gravel. They also serve to channel oil, water, and other fluids away from the contact points of the sole, allowing it to make a more direct connection with the underlying surface.

The Importance of a Defined Heel

A feature often overlooked is the 90-degree defined heel. This creates a sharp edge that is essential for securely catching on ladder rungs or the edge of a platform.

Boots with a wedge or undefined heel offer significantly less safety when climbing, a common activity on any rig.

Understanding the Trade-offs

No single outsole design is perfect for every possible condition. It's important to recognize the inherent compromises.

Aggressive Treads vs. Clogging

While deep, aggressive lugs are excellent for mud, they can become clogged with thick clay or debris. When the lugs are filled, the outsole can become a slick, flat surface, negating its traction advantage.

Hardness vs. Grip

Softer rubber compounds often provide superior grip on smooth, wet surfaces like steel grating because they have more "stickiness." However, they tend to wear down much faster.

A harder, more durable compound will last longer but may offer slightly less grip on those same smooth, slick surfaces.

Specialized vs. All-Purpose Outsoles

Some outsoles are specifically designed for ice or extreme cold, using compounds that stay flexible at low temperatures. While excellent in those conditions, they may not offer the same durability or oil resistance as a standard rig boot.

Making the Right Choice for Your Role

Selecting the right boot depends entirely on your primary work environment and tasks.

- If your primary focus is working on the rig floor: Prioritize a boot with a high-quality, oil-resistant rubber compound and lug patterns designed to channel away fluids.

- If your primary focus is working across varied, undeveloped terrain: Look for deep, aggressive lugs that can bite into soft ground like mud and gravel.

- If your primary focus involves frequent climbing: Insist on a boot with a well-defined, 90-degree heel for maximum safety on ladders and rungs.

Ultimately, your boots are a critical piece of personal protective equipment designed to keep you stable and safe in a hazardous world.

Summary Table:

| Traction Factor | Why It Matters | Key Boot Feature |

|---|---|---|

| Slippery Contaminants | Oil, grease, and mud create hazardous surfaces. | Oil- and slip-resistant outsole compound (e.g., specialized rubber, TPU). |

| Uneven Terrain | Surfaces change from metal grating to mud and gravel. | Aggressive lug patterns for grip and fluid channeling. |

| Dynamic Work Tasks | Climbing, lifting, and pushing require stable footing. | Defined 90-degree heel for secure ladder climbing. |

Equip Your Team with Boots Built for Maximum Traction

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. We understand that for workers on drilling sites and production facilities, traction isn't just a feature—it's a fundamental requirement for safety and performance.

Our production capabilities encompass all types of oilfield boots and work boots, engineered with the specific outsole compounds, lug patterns, and heel designs detailed in this article to mitigate the risks of slips, trips, and falls.

Let us help you source the right safety footwear for your specific operational hazards. Contact our team today to discuss your requirements and discover how 3515 can be your reliable partner in worksite safety.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Grain Leather Safety Boots for Bulk Supply

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- How do PVC work boots compare to rubber boots? Choose the Right Material for Your Job

- What are the primary uses and characteristics of cowboy boots? From Workhorse to Fashion Statement

- What factors should be considered when choosing work cowboy boots? A Guide to Safety, Durability & Comfort

- How do men's winter work boots differ from casual boots? Choose the Right Footwear for Safety & Style

- What environmental conditions damage firefighter boots? The Hidden Cycle of Heat, Water & Chemicals

- What materials are commonly used for the upper part of work boots? Full-Grain Leather vs. Synthetics Explained

- What are the characteristics of nylon work boots? Lightweight, Breathable & All-Day Comfort

- What are the requirements for impact resistance in safety toe boots? Ensure Maximum Protection for Your Workforce