Traction is the single most critical safety feature in winter boots. Its importance stems from the need to maintain a secure grip on treacherous winter surfaces like ice, packed snow, and slush, directly preventing slips, falls, and potential injury. Boots designed for these conditions use specific materials and outsole designs to maximize friction and stability when you need it most.

The core challenge of winter footwear isn't just warmth; it's maintaining stability on unpredictable, low-friction surfaces. Effective traction is the engineered solution that provides the necessary grip to counteract the dangers of ice and snow.

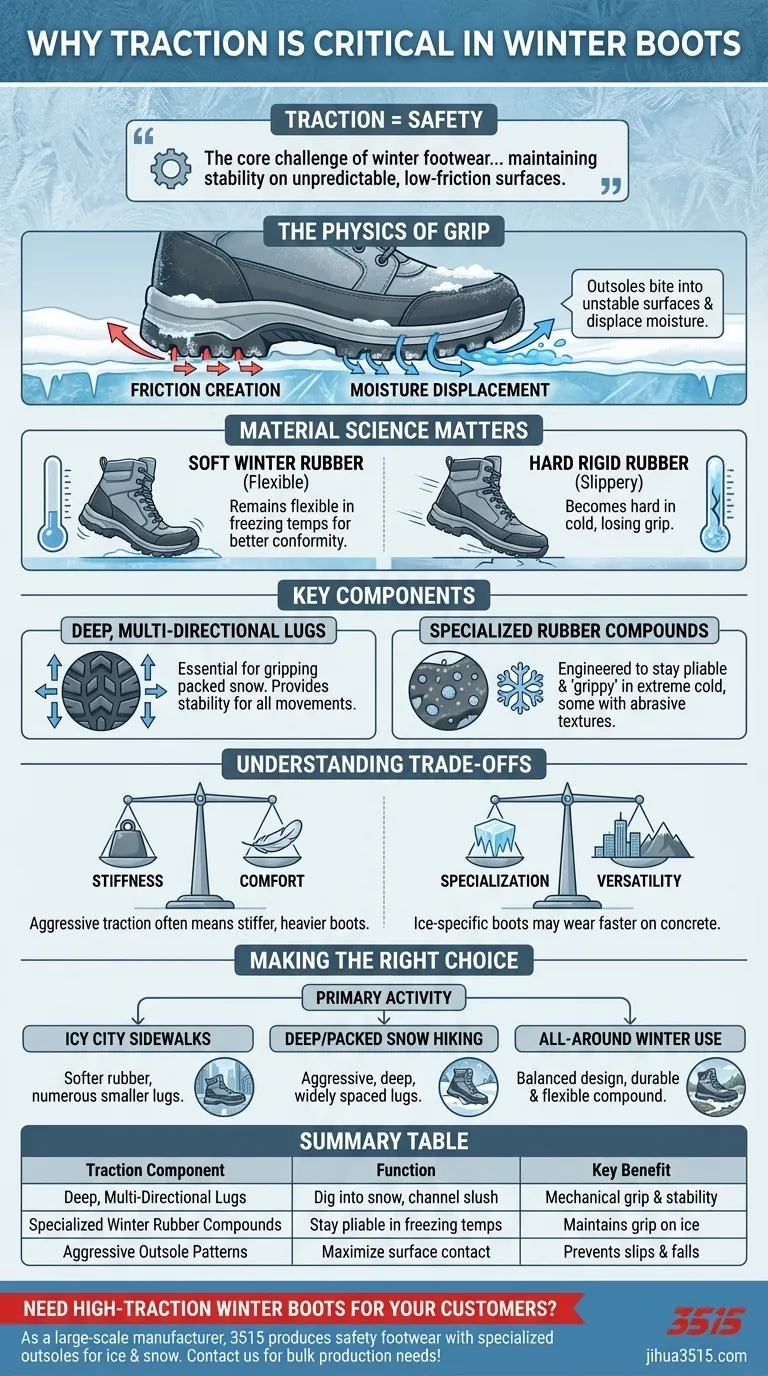

How Traction Prevents Winter Slips

Winter environments present a unique challenge to footwear. Unlike a dry sidewalk, surfaces like ice and snow constantly change and offer very little natural friction for a standard shoe.

The Physics of Grip

Traction is fundamentally about creating friction. An effective winter boot outsole is designed to bite into unstable surfaces and displace moisture.

The deep grooves, or lugs, on a winter boot's outsole act like teeth. They dig into snow for a mechanical grip and channel water and slush away from the sole's contact points.

The Role of Material Science

The material of the outsole is just as important as its design. Softer rubber compounds are often used because they remain flexible in freezing temperatures.

A rubber that becomes hard and rigid in the cold loses its ability to conform to the ground, significantly reducing its grip on slick surfaces.

Key Components of High-Traction Boots

When evaluating a boot's traction, you need to look at both the pattern and the substance of its outsole. These two elements work together to provide stability.

Deep, Multi-Directional Lugs

Lugs are the deep, patterned indentations on the bottom of the boot. Deep lugs are essential for gripping packed or loose snow.

Multi-directional patterns are crucial because they provide grip whether you are walking uphill, downhill, or stopping suddenly. This ensures stability no matter how you move.

Specialized Rubber Compounds

Look for boots that specify their use of a winter-grade rubber outsole. These materials are engineered to stay pliable and "grippy" even when the temperature drops well below freezing.

Some advanced outsoles even incorporate abrasive materials directly into the rubber, creating a texture similar to sandpaper for an enhanced grip on pure ice.

Understanding the Trade-offs

Superior traction often comes with compromises in other areas. Understanding these helps you choose a boot that fits your specific needs.

Stiffness vs. Comfort

Boots with aggressive, deep lugs and rigid outsoles offer phenomenal traction but can feel stiff and less comfortable for casual, all-day wear on dry pavement.

The most protective outsoles are often heavier, which can lead to fatigue over long distances compared to a lighter, more flexible boot.

Specialization vs. Versatility

A boot designed exclusively for gripping ice might use very soft rubber that wears down quickly if used primarily on concrete or asphalt.

There is no single boot that excels in every possible condition. A boot for deep snow hiking will have a different traction design than one meant for icy city sidewalks.

Making the Right Choice for Your Goal

Your primary activity dictates what kind of traction is most important.

- If your primary focus is walking on icy city sidewalks: Prioritize boots with softer rubber compounds and numerous, smaller lugs that maximize surface area contact with flat, slick ice.

- If your primary focus is hiking in deep or packed snow: Look for boots with aggressive, deep, and widely spaced multi-directional lugs that can bite into the snow and shed it easily.

- If your primary focus is all-around winter use: Seek a balanced design with moderately deep lugs made from a durable but still flexible cold-weather rubber compound.

Ultimately, choosing a boot with the right traction is a direct investment in your safety and confidence during the winter months.

Summary Table:

| Traction Component | Function | Key Benefit |

|---|---|---|

| Deep, Multi-Directional Lugs | Dig into snow and channel away slush | Provides mechanical grip and stability on uneven terrain |

| Specialized Winter Rubber Compounds | Stay pliable in freezing temperatures | Maintains grip on slick surfaces like ice |

| Aggressive Outsole Patterns | Maximize surface contact and friction | Prevents slips and falls on unpredictable winter surfaces |

Need high-traction winter boots for your customers? As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear with specialized outsoles designed for ice, snow, and harsh conditions. Our boots feature deep lugs and winter-grade rubber compounds to ensure maximum grip and durability for distributors, brand owners, and bulk clients. Enhance your winter footwear lineup with reliable, safety-focused designs — contact us today to discuss your production needs!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Insulated Safety Boots and Shoes for Wholesale & Bulk Orders

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

People Also Ask

- What are the advantages of full-grain leather hunting boots? Unmatched Durability & Custom Fit

- How do waterproof boots improve hygiene? Keep Your Feet Dry and Healthy

- Can hunting boots be repaired? Extend the Life of Your Favorite Gear

- What is the verdict on short riding boots? The Ultimate Guide to Comfort & Versatility

- Is scent more important than boot color in hunting? Master Stealth with Scent Control First

- Why are sandy surfaces considered a critical factor in the study of slip resistance for outdoor and construction footwear? Essential for Worker Safety.

- What are the boot requirements for warm and humid hunting conditions? Prioritize Breathability to Stay Cool

- What are sport and racing motorcycle boots and their key attributes? Essential Protection for High-Speed Riding