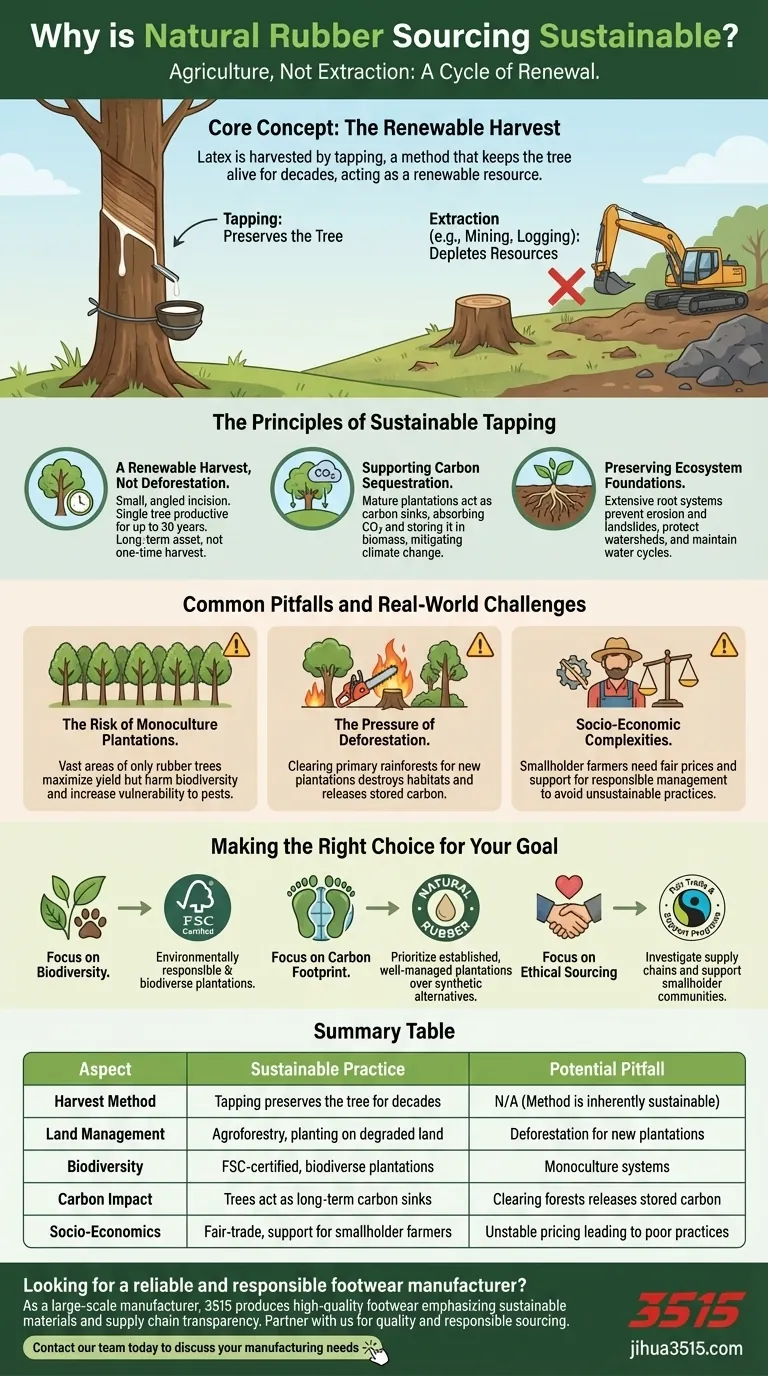

At its core, the sourcing process for natural rubber is considered sustainable because it is a form of agriculture, not extraction. The latex is harvested by tapping the Hevea brasiliensis tree, a process that does not require the tree to be cut down. This allows a single tree to remain productive for decades, acting as a renewable resource while keeping the forest canopy intact.

The inherent sustainability of natural rubber comes from the tapping method that preserves the tree. However, its true environmental impact depends entirely on how the rubber plantations are managed—ranging from ecologically damaging monocultures to biodiverse agroforestry systems.

The Principles of Sustainable Tapping

The method of harvesting latex is fundamentally different from resource extraction methods like mining or logging. It is a cycle of renewal that, when managed correctly, can offer significant environmental benefits.

A Renewable Harvest, Not Deforestation

The process involves making a small, angled incision in the tree's bark to collect the milky latex sap that flows out. This tapping is carefully managed to ensure the tree's health and longevity.

A single rubber tree can be tapped for up to 30 years, making it a long-term, renewable asset rather than a one-time harvest. This stands in stark contrast to agricultural practices that require annual clearing and planting.

Supporting Carbon Sequestration

Like any forest, a mature rubber plantation acts as a significant carbon sink. The trees absorb carbon dioxide from the atmosphere throughout their long lives, storing it in their biomass.

By keeping these trees standing and healthy for decades, well-managed rubber sourcing contributes directly to mitigating climate change.

Preserving Ecosystem Foundations

The extensive root systems of rubber trees help to anchor the soil, preventing erosion and landslides, particularly in tropical regions with heavy rainfall.

These plantations also play a role in maintaining the local water cycle and protecting watersheds, benefits that are lost when land is completely cleared for other uses.

Common Pitfalls and Real-World Challenges

The sustainable potential of natural rubber is not always realized in practice. The distinction between ideal methods and on-the-ground reality is critical for a complete understanding.

The Risk of Monoculture Plantations

Many large-scale operations plant vast areas with only rubber trees. This monoculture approach maximizes yield and simplifies harvesting but is detrimental to biodiversity.

Monoculture forests cannot support the complex web of plant and animal life found in natural ecosystems and are more vulnerable to pests and disease.

The Pressure of Deforestation

While tapping itself is sustainable, the demand for rubber can still drive deforestation. New plantations are sometimes established by clearing primary rainforests, which destroys irreplaceable habitats.

The sustainability claim is only valid when rubber is grown on previously degraded land or within well-managed systems that do not replace native forests.

Socio-Economic Complexities

True sustainability must also include social and economic factors. The industry relies heavily on smallholder farmers, who produce the majority of the world's natural rubber.

Ensuring these farmers receive fair prices and have the resources for responsible land management is crucial. Unstable pricing can pressure them into unsustainable practices to make ends meet.

Making the Right Choice for Your Goal

Evaluating the sustainability of a specific rubber source requires looking beyond the material itself and investigating its origin and the practices used to produce it.

- If your primary focus is biodiversity: Seek out rubber certified by the Forest Stewardship Council (FSC), which guarantees it comes from environmentally responsible and biodiverse plantations.

- If your primary focus is carbon footprint: Prioritize natural rubber from established, well-managed plantations over synthetic, petroleum-based alternatives.

- If your primary focus is ethical sourcing: Investigate supply chains for fair-trade certifications and programs that provide direct support to smallholder farming communities.

Ultimately, understanding these nuances empowers you to assess whether a product truly aligns with its environmental claims.

Summary Table:

| Aspect | Sustainable Practice | Potential Pitfall |

|---|---|---|

| Harvest Method | Tapping preserves the tree for decades | N/A (Method is inherently sustainable) |

| Land Management | Agroforestry, planting on degraded land | Deforestation for new plantations |

| Biodiversity | FSC-certified, biodiverse plantations | Monoculture systems |

| Carbon Impact | Trees act as long-term carbon sinks | Clearing forests releases stored carbon |

| Socio-Economics | Fair-trade, support for smallholder farmers | Unstable pricing leading to poor practices |

Looking for a reliable and responsible footwear manufacturer?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality footwear for distributors, brand owners, and bulk clients. We understand the importance of sustainable materials and supply chain transparency. Our production capabilities encompass all types of shoes and boots, ensuring durability and performance.

Partner with us to ensure your products are built on a foundation of quality and responsible sourcing.

Contact our team today to discuss your manufacturing needs.

Visual Guide

Related Products

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

People Also Ask

- How do the heights of rain boots and snow boots compare? A Guide to Weather-Ready Footwear

- What are rain boots made of? Discover the best materials for ultimate waterproof protection.

- What materials are used in snow boots and rain boots? A Guide to Waterproof Footwear

- What are the distinctive features of rain boots? Unmatched Waterproof Protection Explained

- What are the liner materials for rain boots? Cotton vs. Blends for Comfort & Durability