In footwear design, materials are not just a component; they are the foundation. The selection of materials is arguably more critical than the shoe pattern itself because it dictates whether a design idea can be successfully transformed into a functional, durable, and manufacturable product. The right material choice ensures a shoe performs as intended, while the wrong one can lead to failures like ripping during production or fading in the sun.

Choosing the right material is a strategic decision that balances a shoe's intended function, aesthetic vision, and production reality. Getting this decision wrong compromises every other aspect of the design.

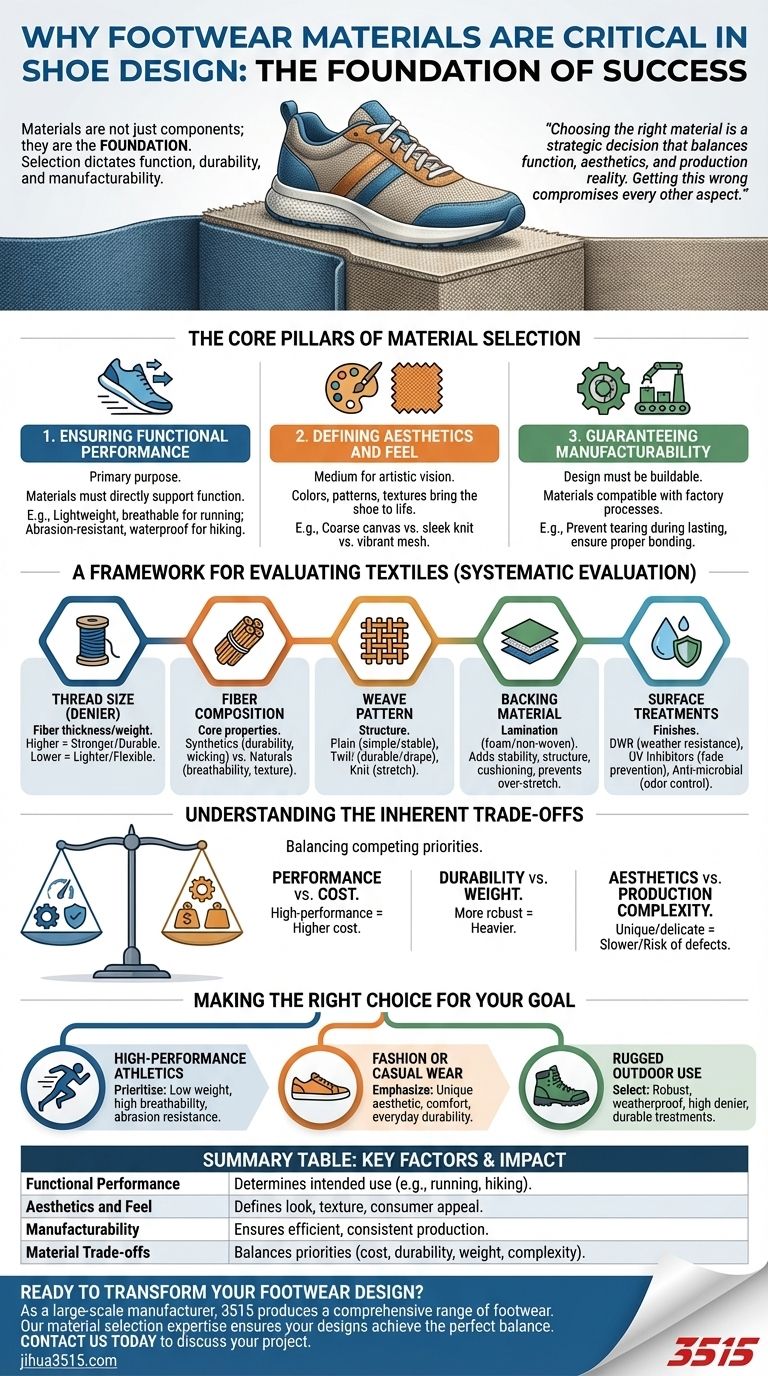

The Core Pillars of Material Selection

A material does more than just cover the foot; it defines the shoe's entire existence, from the factory floor to the end user's experience. Understanding its role is key to successful design.

Ensuring Functional Performance

The primary purpose of any shoe is functional. The materials chosen must directly support that function.

A running shoe requires lightweight, breathable, and flexible textiles. A hiking boot demands abrasion-resistant, waterproof materials. The material dictates the shoe's performance capabilities.

Defining Aesthetics and Feel

Materials are the medium for the designer's artistic vision. They bring the shoe to life through color, pattern, and texture.

Textiles, in particular, offer a nearly infinite variety of options. The choice between a coarse canvas, a sleek knit, or a vibrant synthetic mesh fundamentally changes the shoe's character and consumer appeal.

Guaranteeing Manufacturability

A brilliant design is useless if it cannot be built efficiently and consistently. Materials must be compatible with factory processes.

Some materials may tear under the strain of a lasting machine, while others may not bond well with adhesives. Selecting production-friendly materials prevents costly delays and quality control issues.

A Framework for Evaluating Textiles

When working with textiles, a systematic evaluation is necessary. Five key factors determine how a fabric will perform in a footwear application.

Thread Size (Denier)

This refers to the thickness and weight of the fiber. A higher denier generally indicates a stronger, more durable fabric, while a lower denier offers a lighter weight and greater flexibility.

Fiber Composition

The type of fiber—such as polyester, nylon, cotton, or wool—determines the material's core properties. Synthetics often provide durability and moisture-wicking, while natural fibers can offer breathability and a distinct texture.

Weave Pattern

The way fibers are interlaced creates the fabric's structure. A plain weave is simple and stable, a twill weave is durable and drapes well, and a knit construction offers inherent stretch.

Backing Material

Many footwear textiles are laminated with a backing material, such as foam or a non-woven fabric. This adds stability, structure, and cushioning, preventing the primary fabric from over-stretching.

Surface Treatments

Finishes and coatings can add critical performance features. These can include Durable Water Repellent (DWR) coatings for weather resistance, UV inhibitors to prevent fading, or anti-microbial treatments to control odor.

Understanding the Inherent Trade-offs

Material selection is never about finding one "perfect" option. It is always an exercise in balancing competing priorities.

Performance vs. Cost

High-performance materials with advanced properties almost always come at a higher cost. The challenge is to meet the necessary performance targets within the product's budget.

Durability vs. Weight

For performance footwear, this is a classic dilemma. A thicker, more robust material will increase longevity but will also add weight, potentially hindering athletic performance.

Aesthetics vs. Production Complexity

A unique, delicate material may create a stunning visual but can be a nightmare on the production line. Such materials may require slower, more specialized handling, increasing costs and the potential for defects.

Making the Right Choice for Your Goal

Your final material decision should be guided by the primary objective of your design.

- If your primary focus is high-performance athletics: Prioritize materials with specific functional properties like low weight, high breathability, and exceptional abrasion resistance.

- If your primary focus is fashion or casual wear: Emphasize aesthetic qualities like unique colors, textures, and weaves, while ensuring sufficient comfort and durability for everyday use.

- If your primary focus is rugged outdoor use: Select robust, weatherproof materials with high denier counts and durable surface treatments to withstand the elements.

Ultimately, mastering material selection is what separates a mere concept from a successful, market-ready shoe.

Summary Table:

| Key Factor | Impact on Shoe Design |

|---|---|

| Functional Performance | Determines if the shoe meets its intended use (e.g., running, hiking). |

| Aesthetics and Feel | Defines the shoe's look, texture, and consumer appeal. |

| Manufacturability | Ensures the design can be produced efficiently and consistently. |

| Material Trade-offs | Balances priorities like cost, durability, weight, and complexity. |

Ready to transform your footwear design into a market-ready product? As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our expertise in material selection ensures your designs achieve the perfect balance of function, aesthetics, and manufacturability. Contact us today to discuss your project and leverage our full production capabilities for all types of shoes and boots.

Visual Guide

Related Products

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Durable Canvas Work Shoes with Rubber Lug Sole | Wholesale Manufacturer

- Premium Safety Shoes with Rotating Buckle Safety Sneakers

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- Why is structural stability in footwear required during dual-task walking tests? Ensure Sensor Precision & Data Integrity

- What factors influence the healing time of ankle fractures? Optimize Your Recovery Journey

- What is the primary function of an on-board SD card storage module within a human safety monitoring node?

- Can a shoe have mixed certification levels across tests? Yes, Here's Why It Matters.

- How do automated knitting technologies improve occupational risk management? Boost Safety with Advanced Machine Controls

- What temperature range is considered winter for cycling? Master the Layering System for Cold Rides

- Why is it necessary for a footwear manufacturer to maintain a production range from safety shoes to formal dress shoes?

- How does the use of standardized equipment assist in identifying mechanical risk points? Expert Load Testing Insights